By now you've heard many times about the revolutionary new coil spring suspension that Dodge engineers put in the back of the 2009 Dodge Ram 1500 pickup. You've also heard us rave about how much we like it, whether driving it around empty, towing, hauling or off-roading.

This suspension played no small part in the Ram's victory in our recent 4-way truck comparison test in which it defeated the other main players in the 1/2-ton truck market from Ford, Chevy and Toyota.

But we've never actually shown you that suspension...until now.

Dodge calls this "link-coil" rear suspension. The name fits because the solid live axle is located by 2 links per side (white) and the truck is supported by coil springs (black) instead of the usual leafs we see in other pickups.

Other manufacturers use the term "5-link" suspension, for reasons we shall see in a moment.

Did I just say other manufacturers? Isn't Dodge out in front of the curve, here? Well, yes and no.

Every full-size SUV on the market had this type of rear suspension at one time, before all of them (except notably the Tahoe/Yukon/Escalade and their long-wheelbase counterparts) eventually switched to fully independent suspension. The Chevy Avalanche and earlier Ford Exploer Sport used link-coil too, because those vehicles are more of an SUV with a portion of the roof cut off than a full-blown pickup truck.

Chevy tried coil springs on the back of their two-wheel drive 1/2-ton trucks in the 60's, but that was a twin trailing arm design. GMC trucks never adopted it, and Chevy later dropped the idea, but the configuration lives on in NASCAR stock cars and numerous hot rods under the name "truck arm" rear suspension.

Dodge is unique here because they've gone ahead and put 5-link rear suspension on their bread-and-butter 1500-series pickups, 4x2 and 4x4 alike. This type of coil spring suspension is actually a boon off-road because it provides better articulation over obstacles than leaf springs. And coil springs are more than up to the task of handling the loads in the back of a 1/2-ton truck such as this.

But the real payoff here is superior unladen ride and improved cornering stability, as coils have less unsprung mass and they have none of the stick-slip friction found between the rubbing leaves of leaf springs.

Dodge retains leaf springs for it's new 2500 and 3500-series trucks because it is easier to progressively "stage" the spring stiffness of leaf springs when payload capacities get extremely high, as they do in these heavy-duty pickup trucks. Besides, these HD versions don't need to be as concerned about unladen ride comfort because they are more highly-focused as work trucks.

Truck-arm suspension uses one massive trailing arm per side, and that means the nose angle of the rear differential (yellow) changes in an unfavorable way. The only way around the problem is to make the truck arms as long as the driveshaft, but that eats up a lot of space and adds a bunch of weight. Space was less of a problem in the 60's when truck gas tanks were placed outside the frame rails, but modern safety practices put those tanks between the rails, leaving no room for so-called truck arms.

But here a pair of shorter links (white) are used on each side. The space between them prevents axle windup and their differing lengths controls the nose angle of the differential (yellow) in such a way that the u-joints in the driveshaft run much more smoothly and with less vibration through their entire range of motion, something that can't be said for leaf springs or truck arms. As a bonus, the links nest up against the natural curve of the frame rails, so they also take up less space.

Leaf spring suspensions attempt to combat windup by using staggered shock absorbers--one leans forward and the other leans back. But the Dodge setup doesn't need staggered shocks, so they both lean forward like the one shown above.

The coil spring (white) sits atop the axle and extends alongside the frame rail so it can be as long as possible. A urethane bump-stop (yellow) sits just inboard.

We've seen the four trailing links (two per side), and this lateral link brings the total up to five. Called a Panhard rod, it attaches to a bracket on the axle on the left side (yellow) and the frame on the right side (white). The panhard rod is the component that carries all of the lateral loads, and that's why these brackets are so massive.

Leaf spring trucks don't have any such lateral link, so the leaf ends and shackles have to hold fast against lateral loads--a job they're not particularly good at. That's one reason why a leaf- spring truck can sometimes seem jumpy or jittery when encountering rough surfaces.

A rear stabilizer bar is another thing you won't see on a leaf-sprung truck, primarily because the leaves themselves and the staggered shocks use up the available space. But 5-link suspension provides plenty of room for a rear stabilizer bar, and all Dodge Ram 1500 trucks have one.

This application is about as exposed and easy to see as any you'll ever find, with the stabilizer bar (yellow) bolted to brackets on the axle housing and the end links (white) stretching up to meet fixed points on the frame.

Stab bar 101: As the frame & body rolls relative to the axle (ground), these links impart a twist on the bar, which generates a resistive torque that feeds back through the links. A larger bar will therefore generate more force and offer more resistance to body roll. But no such twist is generated if both wheels strike a bump at the same time and the bar pivots harmlessly in its bushings.

You might think that 4 trailing links, a lateral panhard rod and a stabilizer bar would make this setup weigh more than a simple pair of leaf springs. You'd be wrong. Dodge says this design weighs some 40 pounds less than the leaf spring design it replaced. That's because the leaf springs themselves are solid and HEAVY, whereas the five links seen here are simple hollow tubes.

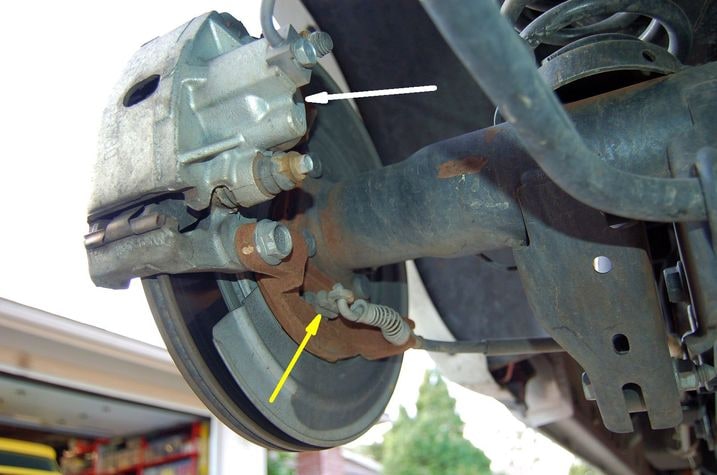

Rear disc brakes with ventilated rotors are used on all Ram 1500 trucks.

Familiar single-piston (white) sliding calipers are used, but the parking brake is a mechanically-actuated (yellow) drum brake that acts upon a rotor with a drum-in-hat profile.

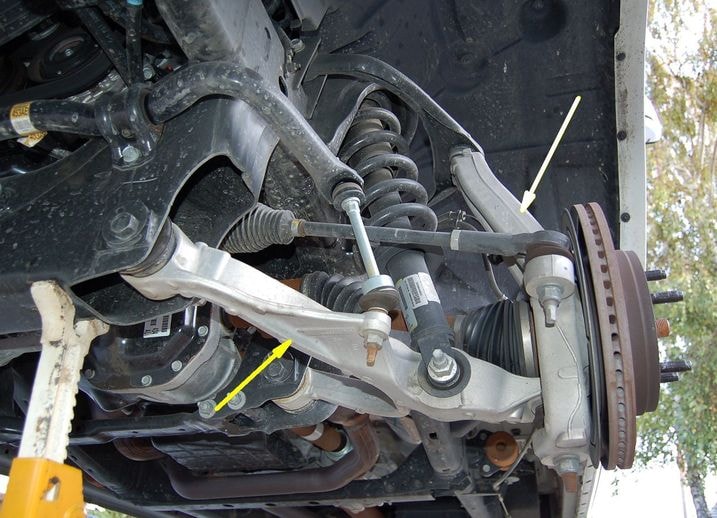

Up front, the 2009 Dodge Ram 1500 rides on double wishbone suspension with a high-mount upper arm.

The lower control arm (yellow) and the front knuckle (white) are made of aluminum.

The front brakes utilize two-piston sliding calipers and ventilated rotors.

As we've seen before, the upper control arm is angled to provide a fair amount of anti-dive geometry.

The coil-over spring/shock assembly (yellow) and the stabilizer bar link (black) attach at intervals along the lower control arm, meaning their motion ratios are something less than 1:1.

The routing and operation of the front stabilizer bar is nearly as easily to visualize as the rear bar.

Our Ram wears the optional 20" wheels with chrome facings. The tires are P275/60R20 Goodyear Wranglers and the mounted assemblies weigh 76.5 pounds apiece.

As you can see, these wheels measure 20-by-9 inches and they have a 19.05 mm offset. 19.05 mm? Are they serious? Yes they are, because 19.05 mm is exactly 3/4 inches.

The chrome facing is in reality an elaborate plastic wheel cover that is permanently fused to the aluminum alloy wheel beneath. I don't recommend these optional wheels if you plan to go off-road, because a) 20" wheels are not the best off-road choice because they lack sufficient sidewall and b) trailside rocks can easily flip up and create an ugly gouge in the flashy chrome cover. In fact this is precisely what happened to me while off-roading a new F-150 with a similar wheel treatment. And c) these chrome facings fall into that category of "fake chrome" that I hate. This type of plasti-chrome looks no more like real metal than the plastic chrome parts found in your typical Revell model car kit. This wheelmaking trend must die.

Dan Edmunds, Director of Vehicle Testing @ 13,650 miles