- The P Zero was originally introduced in 1985.

- Pirelli's high-performance tire comes in a few flavors.

- Development is equal parts virtual and physical.

Behind the Scenes of Pirelli's New P Zero Performance Tire

How Pirelli reinvented one of its most iconic tires

To many drivers, tires are the unsung heroes of modern mobility. Even with all the cool new technology packed into every vehicle on the road, your tires are the only part of that vehicle that actually comes in contact with the ground. They're responsible for handling all the power, turning and stopping the vehicle safely and predictably for the entirety of their lives. So, you know, no big deal.

Tires might go unnoticed by most drivers, but those who know know about the Pirelli P Zero. It's an icon of the automotive industry, so when Pirelli introduced the newest generation of its performance tire and offered me a chance to get a behind-the-scenes look into its development, I jumped at the chance.

Where it started and where it's going

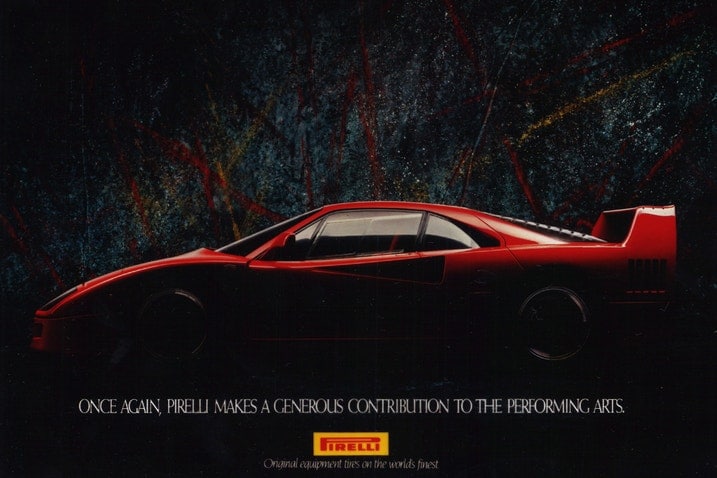

Fittingly, 2025 marks the 40th anniversary of the P Zero's introduction. Originally developed for the growing number of fast (for the era) turbocharged and supercharged cars, the P Zero turned out to be the first modern ultra-high-performance (UHP) tire. Fun fact: The P Zero was still under development when the Lanica rally team used it as the road tire to get their legendary 037 between stages. During a particularly wet day, driver Miki Biasion liked the tire so much that he demanded he run it during the next stage. He did, and he won the stage. On a street-legal tire.

Ever since then, the P Zero has found itself used as standard equipment on some of the hottest cars of their respective generations. In fact, the P Zero has been produced in over 3,000 variations for everyone from specialist automakers like Pagani and McLaren to more mainstream companies like Audi and Jaguar Land Rover.

There's not a singular P Zero model. Instead, it's a family of UHP tires engineered for different types of vehicles and performance envelopes. Ranging in size from 18 to 23 inches (remember high-performance 16-inch tires?), the P Zero range includes the eponymous model but offers an even higher-performance variant, the P Zero R, for rapid road machines like the Porsche 911 GTS hybrid and the Lamborghini Urus. If you want to go faster still, and do most of that driving on a racetrack, there's the P Zero Trofeo RS. Our own Mustang Dark Horse uses these tires as standard equipment, but you've also seen them on the bonkers Porsche Taycan Turbo GT and the Lucid Sapphire in the fastest episode of U-Drags ever.

The P Zero range includes the E model, featuring the use of over 55% natural or recycled materials in its construction, and the Winter 2 for, you guessed it, colder climates. Another cool feature, and definitely something we're likely to see more of in the future, is the Pirelli Cyber Tire. The tire is fitted with a small transmitter (check out the photo of the wheel cutaway) that sends vital information, such as tire temperature and pressure, to the vehicle's electronic control unit, where it can work in conjunction with the car's traction and stability systems to optimize performance and safety. With its algorithms, the tire can also determine the tire's approximate lifespan and alert you when it needs to be replaced. So far, this technology is only available on the Pagani Utopia (I know, I'm still waiting for mine), but the software could be integrated into a vehicle's operating system without too much work.

Behind the scenes

The coolest part of this trip was the rare behind-the-scenes access I had to see some of the development work that goes into a modern tire. While this was all at Pirelli's headquarters, it's safe to say that most major tire manufacturers use similar methods and technology to create and refine their products.

Buried four stories below its corporate buildings and archives (I wish I could have spent more time in those) in Milan, Italy, is one of Pirelli's impressive research and development centers. With high ceilings and too many concrete support pillars to count, unlike the stylish above-ground architecture, this space has not been designed for anything but the testing and development of tires. Everything from a hemi-anechoic chamber to singular tire testing rigs capable of simulating any racetrack in the world to a driving simulator can run up to 24 hours a day, seven days a week.

While most of these rooms run physical tests on prototype tires, the last one I mentioned, the simulation rig, is the new key to tire development. Using virtual prototyping of tires allows for faster and less expensive tire development and also allows manufacturers to send their newest and most secret products in encrypted files for Pirelli to use in the tire development process before either company has developed a physical prototype of their product. Another benefit to virtual tire development is the significant reduction in materials used and their associated emissions. With natural resources being as finite as they are and environmental regulation growing ever more stringent, the virtual process of development really is a look into the future.

by

by  edited by

edited by