2016 Toyota Tacoma: What's It Like to Live With?

Read the latest updates in our long-term road test of the 2016 Toyota Tacoma as our editors live with this truck for a year.

What do you want to know about?

- Introduction

- The Relic That Makes a Difference

- Baptism by Fire Road

- TRD Off-Road vs. TRD Sport

- First Thoughts (Video)

- First Impressions — Better Ride, Touchy Brakes

- Off-Road Clearance and Suspension Flexibility

- Performance Tested

- Seat Folding Maximizes Cargo Capacity

- Fuel Economy Update For January - Initial Observations

- Enjoying the Convenience of a Midsize Short Bed

- Steady On the Brakes

- Keyless Access Only Works On One Door

- Best Off-Road Pick For a Daily Driver?

- Fuel Economy Update for February - Holding at 18 MPG

- V6/Automatic Transmission Combo Doesn't Impress Much

- Clunky Voice Control for Those Without Apple Phones

- Sedona Road Trip Impressions

- March Sees Best- and Worst-Ever Tank Fuel Economy

- Brake Modulation Lacks Finesse

- A Fine First Service

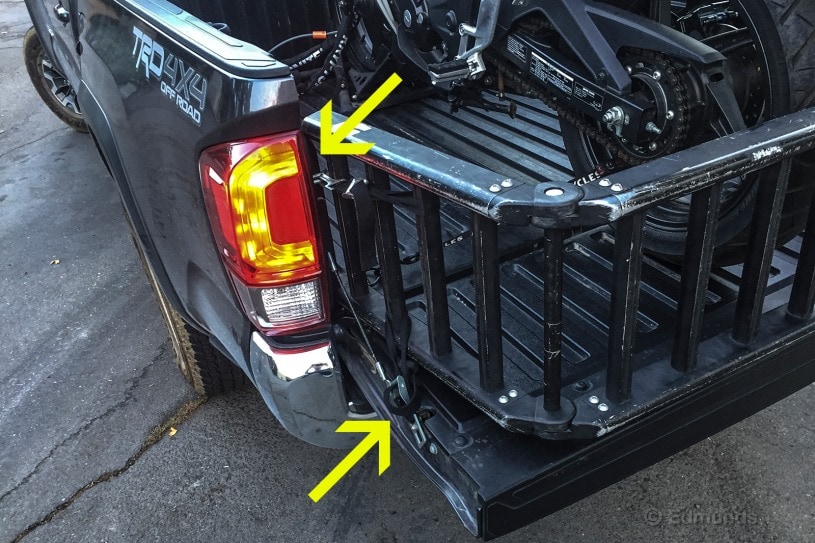

- 8 Great Bed Features

- Of Course the Bike Fits

- Stop For Gas Stupid!

- Fuel Economy Update for April

- Rear Seats are Tight

- The More You Drive It the More You'll Like It

- Wants You To Stay Hydrated

- A Better Radio Knob Suggestion

- One Way To Haul 8-foot Items

- A Devil in a Detail

- A Little Novice Off-Roading

- Less Than Ideal Seating Position

- Fuel Economy Update for May - Show Me the MPG

- More Comfortable on the Highway Than the Old Tacoma, But Still Not Great

- Rear Seat Storage

- Fuel Economy Update for June - Better Range

- Starts Without the Key

- Desert Sessions

- Hauling the Plastic

- July Fuel Economy Update - Despite Road Trips, MPG Stays the Same

- Midsize Truck, Big City

- Refreshingly Simple Climate Controls

- Oh Yeah, It Has a Factory Go-Pro Camera Mount

- Time for New Wiper Blades

- A Transatlantic Perspective

- Good Stereo, Not Great

- September MPG Update - Undramatically Unchanged

- Three Reasons to Buy

- Monthly Update for October 2016

- Easy Loading

- Touchscreen is OK, but Smartphone Integration Lags

- Monthly Update for November 2016

- Rock On

- Monthly Update for December 2016

- Monthly Update for January 2017

- Monthly Update for February 2017

- Monthly Update for March 2017

- Monthly Update for April 2017

- Monthly Update for May 2017

- Monthly Update for June 2017

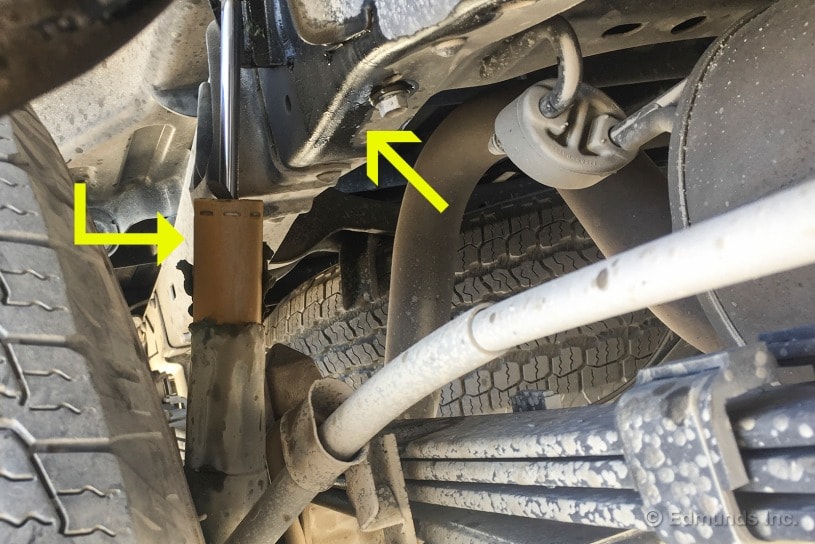

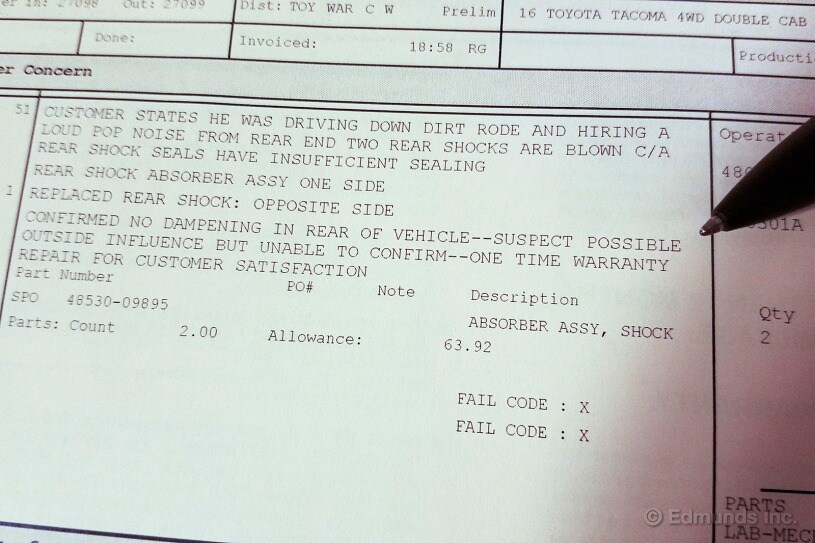

- Suspension Breakdown in Death Valley

- Making Sense of Our Death Valley Results

- Monthly Update for July 2017

- Monthly Update for August 2017

- Monthly Update for September 2017

- Monthly Update for October 2017

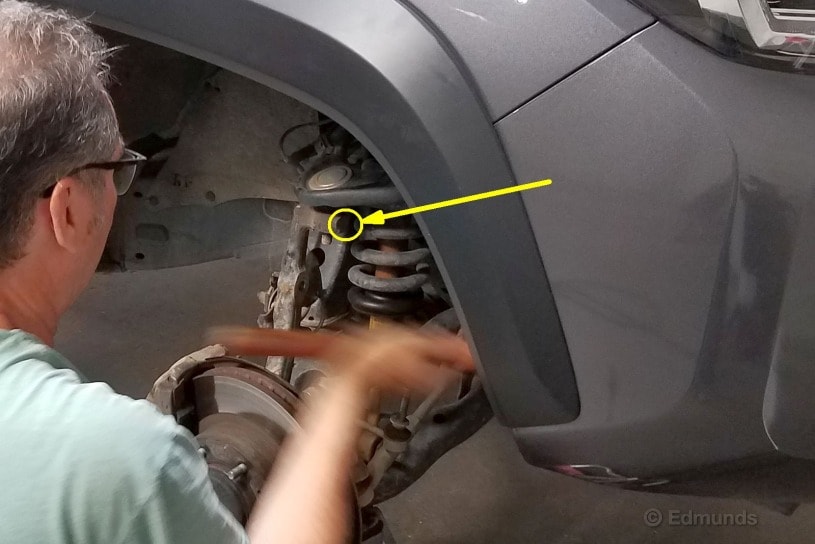

- Bilstein Shock Absorber Upgrade

- Monthly Update for November 2017

- Racetrack Road Revisited

- Wrap-Up

Introduction

What Did We Get?

The Toyota Tacoma has history. It's a workhorse with a reputation for reliability and durability that's known the world over. And it earned that reputation with the easygoing nature offered only in a smaller pickup. As midsize trucks go, it is the standard-bearer.

That reputation is one reason why the redesigned 2016 Toyota Tacoma isn't drastically different from the previous model. There's a new V6 and an improved six-speed automatic. The interior is updated to modern standards that were desperately lacking in the 11-year-old outgoing version. Dimensionally, however, the new truck is almost identical to the one it replaces. Its track width, wheelbase and suspension remain the same as before. It's still very much the same midsize truck it's always been.

That's a good thing in many ways, as we have always liked the Tacoma's rugged nature and considerable capabilities. Our initial drive of the redesigned model suggested that it was a slightly more high-tech version of the truck we already knew. We decided to find out if that was enough of a leap to keep it at the head of the class, so we bought a crew cab V6 of our own.

What Options Does It Have?

There are five trim levels available: SR, SR5, TRD Sport, TRD Off-Road and Limited.

All Tacomas come with a bedliner from the factory. Other standard features across the board include air-conditioning, power accessories, Bluetooth phone and audio connectivity, a rearview camera and a USB port and auxiliary audio jack. Sixteen-inch wheels are nothing new, but are included as standard equipment on every Tacoma except the TRD Sport (17s) and the top-trim Limited, which gets 18s.

We opted for the TRD Off-Road model, as we liked its combination of features and suspension tuning. It includes Bilstein shocks, a lockable rear differential and a crawl control system that allows varying speeds between 1 and 5 mph (only available with automatic transmission versions). It also includes keyless entry, a first for the class.

The 3.5-liter V6 in our truck is good for 278 horsepower and is paired to a six-speed automatic transmission. Its two-speed transfer case is electronically switched.

Additional options include the $650 V6 Tow package, which adds an engine oil cooler, power steering cooler, heavy-duty alternator and a four- and seven-pin electrical connector for a trailer. We also got a $90 exhaust tip and carpeted floor mats for $209, which brought the MSRP to $35,579. We purchased the truck from Carson Toyota, which knocked $500 from the sticker price for a total of $35,079.

Why Did We Buy It?

For the last decade or so, the midsize truck segment was stagnant. The long-running Ford Ranger was killed off, while GM's trucks came and went. The Toyota Tacoma and Nissan's Frontier stuck around, but with little competition they didn't change much.

In 2014, GM got back into the game and rejuvenated the segment. Sales of the Colorado and Canyon have exceeded expectations without stealing sales from their larger siblings. We recently wrapped up a year with Chevy's Colorado in which it proved to be a solid machine. Clearly, there was some unmet demand out there.

This new Tacoma arrived with a familiar look and feel. We couldn't help but wonder if Toyota was underestimating its new rivals. But after some initial seat time and closer inspection of its features and specs, it was clear that this Tacoma wasn't just a quickly arranged refresh. This is a truck designed to appeal to the kinds of truck buyers that have made the Tacoma the class leader, while offering enough new features to keep it fresh.

Now it's time to see if Toyota's latest take on the midsize truck measures up to GM's effort. As similar as the Colorado and Tacoma are in many respects, they have very different characters. We grew to like the Colorado for a variety of reasons, and over the next 12 months and 20,000 miles we'll learn every quirk of the Tacoma, both good and bad.

Follow along on our Long-Term Road Test page to see if the new Tacoma is still the standard when it comes to midsize trucks.

Edmunds purchased this vehicle for the purpose of evaluation.

I've seen the ECT Power switch in Toyota trucks since I was in junior high. I've driven plenty of trucks with the switch. And before this Tacoma, that switch has never made any discernable difference. Now that's changed.

The switch resides on the center stack of our 2016 Toyota Tacoma. I had driven the truck for a day or so before I even noticed it. Then I drove up the longest hill in my neighborhood. We live in the foothills of Orange County's Santa Ana mountains and the houses are built into some real inclines. The one in question rises 450 vertical feet in just over a mile.

Just enough, it turns out, to throw the Tacoma into shift-fits. Be careful how you say that.

The hill is the perfect pitch to create an endless search for the right gear. Try to maintain the speed limit (45 mph) and the Tacoma downshifts. Then speed climbs rapidly and lifting off the throttle is required to maintain the speed limit. As soon as the throttle is closed — even slightly — the transmission upshifts again, the truck begins to lose speed, and the process repeats.

This, friends, is textbook gear hunting. And it's infuriating.

Activating "Power Mode" via the ECT switch essentially solves the problem. Shift points and throttle calibration tweaks let it hold the higher gear up the hill, which is a relief.

It's fairly clear that the Tacoma's stock transmission calibration is a product of a hair-splitting search for fuel economy. It's almost always a gear too high in city driving. Pushing the ECT Power button solves the problem. But should I need to activate an alternate calibration just to drive through my neighborhood?

That didn't take long. I headed for the local mountains the very first weekend I got my mitts on the keys to our brand new 2016 Toyota Tacoma. And it was good.

No, it was excellent.

I'm talking about the TRD Off-Road suspension, which impressed me more than it had during my drive at last summer's launch event near Seattle. Here on my rougher local terrain, it was even better than expected at smoothing out awkward bumps and the sort of rough cross-grain erosion grooves you get on forest service fire roads that haven't seen a grader for a few seasons.

Off-road suspension does not automatically mean stiff suspension. It couldn't be if it were to suck up under-maintained dirt roads like these without rattling the cage containing me and my buddy, Mike.

Due credit goes to the tall and enveloping sidewalls of the Kevlar-reinforced 265/70R16 (a.k.a. 31-inch) Goodyear tires and the 16-inch wheels on which they're mounted, a breath of fresh air in this day and age of "over-dubbing." Do the math and you'll see that these wheels have a full 7.5 inches of rubber protecting them from the rocks and ditches below.

This wouldn't amount to much if the Bilstein monotube shocks weren't tuned to match. A monotube design is preferable out here because such shocks shed heat faster than it can be generated by internal damping valves hammering across washboard and other broken surfaces. But even this does not guarantee success on a wide range of paved and unpaved roads unless the suspension tuning engineers calibrate the damping just right.

They nailed it here. These shocks suck up impacts without jostling the cabin or its occupants. The truck moves as the general shape of the road changes, but the suspension and tires filter out all of the messy and uncomfortable details. Heck, there wasn't even a single squeak or rattle all day.

This truck is tight.

It all translates fairly well onto paved roads, too. The baseline spring tuning stops short of being overly stiff, the tall sidewalls that work well in the rocks do a good job with potholes, and the Bilsteins have the finesse to smooth out the small stuff.

Yes, there is a bit of head toss and some wiggle now and then, but it's all very agreeable, especially considering how capable this truck is on the way to the campsite or mountain bike trailhead.

My head moved as if on a swivel as I wheeled our 2016 Toyota Tacoma into the parking lot of my local Costco and scanned for the nearest open spot. As luck would have it, the first and best one I saw was alongside my truck's doppelganger.

Crew cab? Check. Magnetic Gray Metallic paint? Uh-huh. 3.5-liter V6? Present. Optional 2-inch receiver hitch? Ditto. Brand-spanking new with temporary tags and no license plate? Yes, even that, too.

TRD Off-Road? Hang on a second. That one's a TRD Sport.

Together they represent at least 40 percent of Tacoma sales. The two are identically-equipped as far as interior trimmings go. And they cost exactly the same when the cab, engine, transmission and drive-type selections match. The differences boil down to things we can see here in the parking lot — mostly.

The rear bumper end caps jump out immediately. They're chrome on our TRD Off-Road and painted body-color on the Sport. The fender flare difference is subtle, owing to the particular color of these trucks. They again match the body color on the Sport, but a TRD Off-Road wears textured and unpainted black ones that are more resistant to stone chips and better at concealing the "desert stripe" you get from driving on narrow brush-covered trails.

Up front, the headlights and grille are identical. But the TRD Sport has two things our TRD Off-Road does not have: a hood scoop and an air dam. The hood scoop is pure visual decoration that doesn't connect to anything. The air dam, present on all Tacomas except the TRD Off-Road, is there to bolster the Tacoma's official EPA fuel economy rating.

It's not fitted to the TRD Off-Road because of its negative effects on the approach angle, which on paper is 29 degrees for the TRD Sport and 32 degrees on our TRD Off-Road. Those numbers are measured at the truck's centerline, but the practical difference is far more dramatic (and arguably more meaningful) out where the TRD Off-Road's front tires are exposed to any rocky terrain you may attempt to surmount.

Speaking of tires, the wheel and tire package is perhaps the most impactful functional difference you'd notice at first glance. Both share the same 31-inch rolling diameter, but that's where the similarities end.

The TRD Off-Road rides on 16-inch wheels surrounded by P265/70R16 Goodyear All-Terrain Adventure tires with Kevlar-reinforced sidewalls and an all-terrain tread pattern. In contrast, the TRD Sport wears 17-inch wheels shod with P265/65R17 Toyo Open Country tires with a more pavement-oriented crossover SUV-style tread pattern.

Behind each we can see the dust covers of the shock absorbers peeking out. That splash of blue indicates that our TRD Off-Road is riding on Bilstein monotube dampers. Meanwhile, then plain black dust boots of the TRD Sport indicate it has conventional twin-tube shocks with a more pavement-biased tune.

The stuff we can't see here in the parking lot is not insignificant, and all of it is exclusive to the TRD Off-Road. It has an extra skid plate. It comes with a lockable rear differential, an enhanced stability control system with multiple terrain settings, and a new crawl control system. Switches for these are found inside the cabin in the overhead console area. In the TRD Sport, that space is a sunglasses storage bin.

Trim differences aside, what it comes down to is that the TRD Off-Road comes with a suite of functional off-road equipment while the TRD Sport has a non-functional hood scoop and a more pavement-oriented suspension and tire tune.

For the same money.

I got my first taste of our long-term 2016 Toyota Tacoma, so I set up my iPhone holder and pressed record. Vlog time!

Although there have been various versions of the 2016 Toyota Tacoma in the office over the last few months, I never managed to get behind the wheel. This weekend, I got my first chance to get acquainted with our new long-term Tacoma. Here's what I found:

The biggest takeaway from my commute home and various weekend errands? This Tacoma rides significantly better than before. I'm not convinced it's necessarily better than our Chevy Colorado, but this Tacoma is noticeably less jittery over freeway expansion joints compared to the previous model. It feels closer to a full-size truck in this regard, which is no small feat.

As much as I like the ride quality, I'm less impressed by the brakes. They stop well and all, but the pedal is too touchy for my tastes. They make it hard to stop smoothly in stop-and-go traffic. Hopefully this fades a bit as they break in.

At this early juncture, I'm on the fence about the engine and transmission. Although there's plenty of power once the engine is spinning, I wouldn't mind having a little more meat on the low end. I didn't have a chance to play with the transmission much so I'll reserve judgement for now. At this point it feels much like the Toyota automatics on prior Tacomas.

Overall, I like the refinements made to this truck. I found the previous model more agreeable than most, so I wasn't surprised with the mild redesign. We'll see how long that sentiment lasts.

Off-Road Clearance and Suspension Flexibility

The thing about off-road potential is that you can often simply look at a vehicle, or study certain fundamental specifications, and size it up pretty accurately. Ground clearance is a good one, along with the clearance angle triplets: Approach, departure and breakover. Tire size and the general knobbiness of the tread pattern are plain to see, of course. Gearing is invisible to the casual observer, but you can readily look it up.

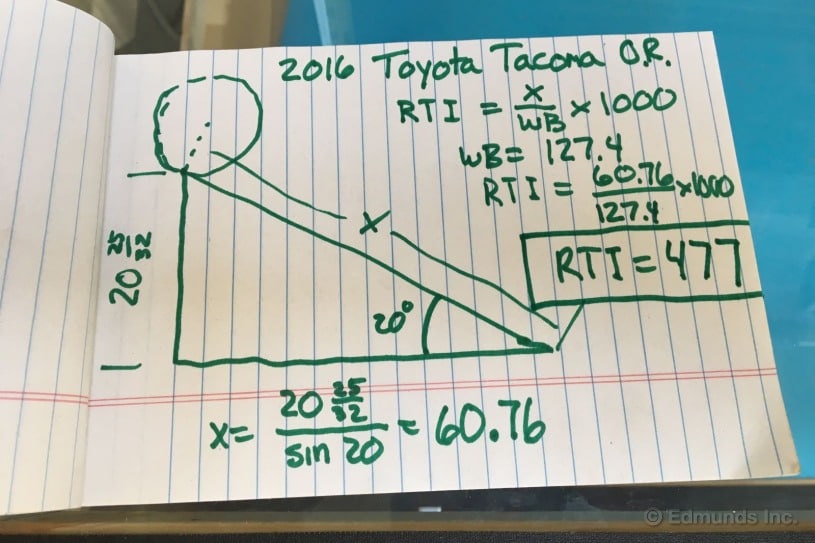

One of the things you cannot see or easily look up is Ramp Travel Index, a measure of the maximum articulation of a given suspension. We had the same problem, so we built a 20-degree test ramp of our own. It was only a matter of time before we pointed our 2016 Toyota Tacoma up the ramp.

We did the same with our 2015 Chevrolet Colorado soon after we bought it last year - or tried to. But the Colorado scored a zero because its comically low and unexpectedly rigid chin spoiler frustrated our attempts to even drive up the 20-degree RTI ramp in the first place.

The story is quite different when it comes to the new Tacoma.

What's that? You didn't catch the ill-fated Colorado RTI test when it appeared? The above photograph tells you everything you need to know.

Short of cutting it off with shears, the job of removing the spoiler was going to take hours because of the way the way the attachment had been designed. We ultimately decided against it after we discovered a passage in the owner's manual that warned against sustained operation with the spoiler absent, citing "improper airflow to the engine."

The whole situation left a bitter aftertaste. Off-road use was way down the list of priorities when the Colorado was designed, it seemed.

The front-end design of the Tacoma, on the other hand, is the result of a much higher expectation that owners will wander off-highway in rugged terrain. The 2016 Tacoma TRD Off-Road has a full eight or 10 inches of clearance above the point where its front tire makes first contact with the ramp - or if you're outdoors, that rock you need to butt up against and creep over.

I can't remember another vehicle this side of a Jeep Wrangler that exhibited this much clear space at this point on the ramp.

The SR5, TRD Sport and Limited versions of the Tacoma wear an air dam, but it's cut much higher than the Colorado and wraps up in the critical area ahead of the front tires. Those versions of the Tacoma would still have plenty of clearance here - more clearance, it appears, than a Colorado would have even if we'd bothered to invest the time to remove its low-hanging spoiler.

How did the numbers work out for the Tacoma TRD Off-Road? It ultimately hiked its left front tire 20.8 inches above ground, which translates into a 20-degree ramp-climb distance of 60.8 inches. Divide that figure by our crew cab short-bed truck's 127.4-inch wheelbase and multiply the result by 1,000 and you'll get 477 RTI points.

The result would be the same for an extended cab long-bed Tacoma because it rides on the same wheelbase.

Our full-size 2015 Ford F-150 and 2014 Ram 1500 scored 420 and 423 points, respectively. The off-road-oriented Ram 2500 Power Wagon managed 412 points in normal mode and 518 with its electronically-disconnecting front stabilizer bar unhinged.

The Toyota Tundra TRD Pro, a more serious off-road package built around a suite of factory-tuned aftermarket parts, was good for 484 points.

Back in 2014, a Range Rover Sport scored 487 points, and the Land Rover LR4 came in at 457 points with its terrain dial in Rock mode, which jacks its air suspension to the highest position. A four-door Jeep Wrangler Unlimited scored 518 points, but that leaps to 687 points if it's a Rubicon with its electronically-controlled front stabilizer bar disconnected.

In other words, the Tacoma's suspension is quite flexible, especially among pickup trucks. And in the process of measuring its RTI, we confirmed what you can see by studying it in a parking lot: It offers abundant clearance where it counts.

Like many trucks, our long-term 2016 Toyota Tacoma shouldn't be judged by its on-road performance alone. The Kevlar-sidewall tires, skid plates and beefed-up suspension are no help here, but there is a reason we chose the TRD Off Road over the TRD Sport.

While we've briefly tested the Taco's off-road capabilities, it's time to see how it performs at the track.

Vehicle: 2016 Toyota Tacoma Double Cab TRD Off Road

Odometer: 1,856

Date: 1/29/2016

Driver: Carlos Lago

Price: $35,579

Specifications:

Drive Type: Four-wheel drive

Transmission Type: Six-speed automatic

Engine Type: Naturally-aspirated V6

Displacement (cc/cu-in): 3,456/211

Redline (rpm): 6,100

Horsepower (hp @ rpm): 278@ 6,000

Torque (lb-ft @ rpm): 265 @ 4,600

Brake Type (front): One-piece discs with two piston sliding calipers

Brake Type (rear): Drum

Suspension Type (front): Coil spring double wishbone with stabilizer bar

Suspension Type (rear): Leaf springs with staggered outboard-mounted gas shocks

Tire Size (front): 265/70R16 112T

Tire Size (rear): 265/70R16 112T

Tire Brand: Goodyear

Tire Model: Wrangler A/T Adventure

Tire Type: Standard All Season with Kevlar sidewall

Test Results

Acceleration:

0-30 (sec): 3.3 (w/ TC on 3.5)

0-45 (sec): 5.6 (w/ TC on 5.8)

0-60 (sec): 8.1 (w/TC on 8.4)

0-60 with 1-ft Rollout (sec): 7.8 (w/TC on 8.0)

0-75 (sec): 11.7 (w/TC on 12.1)

1/4-Mile (sec @ mph): 16.03 @ 89.78 (w/TC on 16.23 @ 88.99)

Braking:

30-0 (ft): 31

60-0 (ft): 124

Handling:

Skid Pad Lateral acceleration (g): 0.66 (0.67 w/ESC on)

RPM @ 70: 1,900

Comments

Acceleration: This V6 is strong through the powerband, but the performance feels great from 4,500-6,000 rpm. The transmission is happy to keep engine parked right in that sweet spot during acceleration runs. The engine is loud, which is acceptable for a truck, but at these speeds the sound has more of a whiney, metallic quality that isn't too appealing.

Best acceleration achieved by hitting the ESC button and holding the brake while applying full throttle. The engine speed won't go above 2,000 rpm doing this, but it's enough to cut 0.2-second off 0-60 mph acceleration. Releasing the brake at this speed causes the tires to bark, but that's all the drama this truck makes on acceleration runs. The transmission has a manual mode, but it didn’t help during acceleration runs. It's slow to react to shift requests and the Tacoma cuts engine power if the engine grazes its 6,000 rpm redline. The transmission does not auto-upshift in manual mode.

Braking comments: You have to expect a certain level of dive/pitch when it comes to a panic stop in a truck and the Tacoma is no exception. The first stop took 123 feet and extended to 132 feet after five back-to-back stops. The ABS is quiet but you notice some shuddering. Stops still feel stable and require no steering corrections. The Tacoma didn't generate odor or fade, though the pedal did get firm. I did notice some brake odor during the following acceleration runs, but no major degradation of braking performance.

Handling

Skidpad: The stability control intervenes continually around the skidpad. You can hear and feel the front brakes cycling and grabbing to keep the Tacoma on its path. Pressing the ESC button illuminates the tell-tale "ESC off" light in the dash, but the system continues to intervene regardless, evident by negligible 0.01-average g difference between ESC on and off runs. While the ESC prevails, it isn't harsh or penalizing. It keeps the truck on its intended path with confidence and makes it easy to direct and steer. You're still facing constant push, but that's expected of a truck — Carlos Lago

Seat Folding Maximizes Cargo Capacity

One of the things that irked me about our 2015 Chevrolet Colorado was the simplistic way its 60/40 rear seat folded. The seatback simply folded down on top of the seat bottom, leaving a slanting surface that was a fair ways up from the ground. The seat bottoms flipped up to reveal a hidden bin, but the available space was laughably small.

I had forgotten most of this until I drove our 2016 Toyota Tacoma to a local store to pick up a few groceries. The Tacoma's rear seat folding strategy differs from that of the Colorado, and it's a difference that makes a difference.

The seat bottoms flip up and forward, which allows for a lower hinge point that enables the seat backs to fold down about six inches lower. And they fold flat and level, with a hard surface that makes a stable platform on which to stack your stuff.

I'm taller than 6 feet and when I'm driving, I need to slide the front seat most of the way back. No problem. I didn't have to scoot my seat forward to make room for the flip-and-fold process.

A fairly generous cubby is revealed when the setback is down. A tow hitch could fit in here, maybe a recovery strap or some motorcycle tie-downs.

And, yes, there's a cubby underneath the seat bottoms. It's similar to what you get in the Colorado, only a fair bit wider. And it does not depend on the seat to be its lid; it has one of its own, with a latch.

Folding the seat bottoms up and down could make it easy to lose track of the seat belt buckles, but Toyota has engineered a solution for that. Stuff the buckle-ends into these pockets and they'll be easy to find after you fold the seat bottom back into the sitting position.

Don't remember what the Colorado looked like? I could have sworn I took a picture with the rear seat folded, but a search of my hard drive turned up nothing.

This GM-supplied image will have to do, even though it has been optimized to improve on reality. The door post is magically absent, for one, and the front seat has been slid at least six inches farther forward that it would have been if I'd have set it to accommodate my lanky frame for an apples-to-apples comparison.

None of that matters. Focus instead on the additional height of the folded stack.

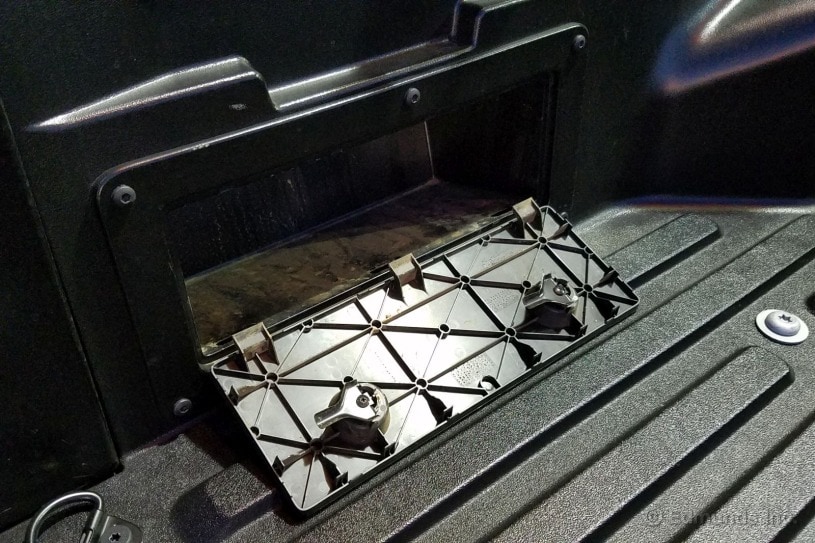

This one is indeed a picture of our long-term test truck, taken with the seat bottoms folded up to reveal the bin below.

It should be no surprise that my vote goes to the Tacoma's backseat folding strategy. The resulting flat surface and considerably lower loading height makes it much more functional. And it's hard to argue with two types of hidden bins that add up to more total cubby storage. Midsize trucks don't have as much interior space to work with as full size trucks do. It pays to make every cubic foot count.

Fuel Economy Update For January - Initial Observations

We're a little overdue but here's our first fuel economy report on our 2016 Toyota Tacoma.

For reference, we've got a 4WD TRD Pro with a 3.5-liter V6 engine and automatic transmission. The EPA says to expect 20 mpg in combined driving. Care to guess what we're averaging so far after the first 2,000 miles?

Worst Fill MPG: 16.9

Best Fill MPG: 19.3

Average Lifetime MPG: 17.8 mpg

EPA MPG Rating: 20 Combined (18 City/23 Highway)

Best Range: 349.0 miles

Current Odometer: 2,125

Is 17.8 mpg disappointing? Maybe a little. But there's not much point in being critical since we're just getting started with our Tacoma. We'll have more to report with February's update in a week or two.

Enjoying the Convenience of a Midsize Short Bed

Want versus need. Keep an eye on what's out on the road and it's immediately obvious that full-size trucks rule the sales charts. And considering that for the price of a new 2016 Toyota Tacoma you can often get within budget range of a discounted or rebated new full-size pickup, going for "more" of what you want certainly makes a lot of sense.

At the same time, you can also make an argument for just getting what you need.

Truth be told, I'm a mediocre stand-in for a truck owner. I don't own any recreational toys (boat, motorcycle, race car). I don't have any big dogs to cart around in the bed. I'm also not often hauling around old engines or cords of wood. Then again, a lot of truck owners I know don't do these things, either.

But I do enjoy the convenience that comes with having a midsize truck at my disposal. Over the weekend I headed to my local nursery to pick up a few bags of potting soil and a few new plants for my backyard. Unlike with a sedan or crossover SUV, I didn't have to worry about whether it would all fit or how I'd protect the interior from dirt or scratches. I just threw everything in our Tacoma's bed, closed the tailgate (newly damped for 2016) and drove off.

I also like the smaller size of the Tacoma compared to a full-size truck. It's easier to park and drive around town. It fits in my garage. The Tacoma's interior also feels right-sized; it's roomy enough take my family (wife, two small children) out to dinner or for errands but not so much as to seem like a waste of space. Compared to our long-term Ford F-150, our Tacoma is about 19 inches shorter and about 6 inches narrower.

Maybe a full-size pickup is still what you want and need. But if you're shopping for a new 2016 truck, there's little harm in at least taking a peek at the new Tacoma.

Our long-term 2016 Toyota Tacoma is a midsize truck with serious off-road capability, and I like that. It seems to compromise some city-driving refinement though, and that I cannot abide. Don't get me wrong, the ride quality is okay for daily driving, but there's a big issue when it comes to the brakes.

The problem with the brakes is right at the end of any braking activity. You know those last two feet before you actually come to a complete stop? Or maybe even the last two inches? It happens right there.

Imagine yourself driving a Tacoma. You see a red light up ahead, you slow progressively, then lighten pedal pressure right before coming to a complete stop. You do this so the heads of all your passengers don't go lurching forward like crash test dummies or so the pizza resting on your back seat doesn't fly off the seat and on to the floor.

In the Tacoma, you can't do that. Heads lurch. Pizza is destroyed. Obi Wan Papa John feels a disturbance in the force and sheds a single tear. I digress. Back to the brakes in our Tacoma.

I've driven the Taco truck with two different pairs of shoes and taken off my shoes altogether just to make sure I wasn't putting undue pressure on the brake pedal. Even with Zen-like concentration, I could only get the Tacoma to stop once without at least some version of its little forward lurch.

Maybe it's the longer travel in the off-road suspension or maybe there's a different compound in the TRD Off Road brake pads. Either way, this thing isn't an ideal city truck, at least not in TRD Off Road trim.

Toyota introduced keyless ignition and entry (Toyota's "Smart Key") as a new feature for the 2016 Toyota Tacoma. The good news: it's pretty easy to get on a Tacoma. If you pick the midgrade TRD (Sport or Off-Road) or top level Limited, you get it as standard equipment.

The bad news: "entry" only works on one door.

Yep, only the driver door recognizes having the key fob in your pocket. Touch the driver door handle and the Tacoma automatically unlocks. Press the ribbed bit of plastic on top of the handle and the door relocks. Neato. But if you want to lock/unlock the other doors from the outside, you'll need to do it the old-timey way: fish the fob out of your pocket/handbag/fanny pack and press the button.

If it's just you and your Tacoma all the time, maybe this isn't that big of a deal. But there have been a few instances now where I've approached the front passenger door or rear doors of our four-door Tacoma (letting my kids in, for instance, or having my hands full with grocery bags or items that I want to store inside the cab) and been annoyed that Smart Key only works on the driver door.

I like that Toyota offers this useful feature on the new Tacoma, but it'd be a lot more useful (and appreciated) if the company made it work on both front doors like just about every other vehicle with this feature. The rear doors would be even better since the rear seating area is often used as the truck equivalent of a car's trunk.

Here's the setup: You're going to buy a new vehicle. You want something that can stomp around in the wilderness for recreation (hiking, camping/fishing, off-roading). But this will also be your daily-driver.

Ideally it's also versatile as well as easy and comfortable to drive.

What's the best new vehicle to get? Would it be a 2016 Toyota Tacoma?

Casting myself as a prospective shopper, I made a list of vehicles that I thought would fit my proposed criteria. (I realize there's a separate and quite valid argument for buying a used vehicle, but I wanted to stick to the new stuff since I'm reporting on our long-term Tacoma here).

Dodge Ram 2500 Power Wagon

Ford F-150 Raptor

Jeep Cherokee Trailhawk

Jeep Grand Cherokee

Jeep Wrangler

Land Rover Range Rover

Mercedes-Benz G-Class

Lexus GX 460

Nissan Frontier

Toyota 4Runner

Toyota Land Cruiser

Toyota Tacoma

If you chose any of these 12 vehicles, I think you'd be in great shape. But there are a few ways that I'd have to narrow down the list. First, price. As cool as it would be to own a G500 or Range Rover, I don't quite have the bank account to support one. If I limit the list to vehicles that cost about the average transaction price for a new vehicle (figure low-to-mid $30,000s), that eliminates the Power Wagon, Raptor, Range Rover, G-Class, GX 460 and Land Cruiser. I could get a Grand Cherokee and a 4Runner for the low 30s, but if I ordered them with the necessary off-road trim levels/equipment, they would break the price barrier. Scratch them off the list.

That leaves us with the Cherokee, Wrangler, Frontier and Tacoma.

All of these meet what I set out to find. But I can narrow it down further. The Wrangler eats granite for lunch but it's the least refined new SUV you can buy. It's not enough of a balanced-use vehicle for me, so I'd take it off the list.

Then there's the Nissan Frontier Pro-4X. Compared to the Tacoma, it's hard to say which one is more capable off road. They have similar dimensions, ground clearance, approach/departure/breakover angles and off-road hardware upgrades. I'll call it a tie. But I do like the Tacoma more for a truck I'd own. It's nicer, more comfortable to drive and has more of the latest available tech. It also enjoys a higher resale value and more aftermarket part support.

Cherokee Trailhawk versus Tacoma TRD Off-Road. Which one would you want?

It's a hard choice for me. The Cherokee Trailhawk is a bit more useful and comfortable on the street. It's better in the dirt than you might think. And it's likely less expensive than the Tacoma by a few grand. But the Tacoma counters with pickup truck utility and an ultimate edge in the off-road category.

My pick is the Tacoma. As my coworker Josh Sadlier says, tell me why I'm wrong.

Fuel Economy Update for February - Holding at 18 MPG

A few weeks ago I belatedly reported on our 2016 Toyota Tacoma's fuel economy for its first month of service. Now I'm back with the second month.

Not much changed.

In February we drove about 1,000 miles and averaged 18.0 mpg. That's a slight improvement over January (17.8 mpg) but still below the EPA's combined driving estimate of 20 mpg. Incidentally, we recorded new best (20.3 mpg) and worst (16.8 mpg) lifetime fill-ups this month.

One of the comments from "5vzfe" on that January update was: "Does the EPA treat the TRD Off-Road to its own individual fuel economy test?" I wondered that myself when I wrote the previous update. There have been instances where a particular vehicle trim level earns a slightly lower or higher mpg rating than the rest of the line. But the EPA website and our vehicle's window sticker do not delineate for the TRD Off-Road.

I will note that most of our long-term test vehicles end up with averages somewhere between EPA city and EPA combined. And we've yet to take our Tacoma on any fuel-economy boosting road trips. So there's still plenty of opportunity for an upswing in the months ahead.

Worst Fill MPG: 16.8

Best Fill MPG: 20.3

Average Lifetime MPG: 18.0 mpg

EPA MPG Rating: 20 Combined (18 City/23 Highway)

Best Range: 349.0 miles

Current Odometer: 3,321

V6/Automatic Transmission Combo Doesn't Impress Much

If you're buying a 2016 Toyota Tacoma you can choose either a 2.7-liter four-cylinder engine or a new 3.5-liter V6, which replaces the Tacoma's previous 4.0-liter V6. The V6 is the obvious choice, mostly because if you're going to tow or haul, you'll want the extra grunt.

Having 278 horsepower is nice and all, but so far our Tacoma's V6 hasn't inspired me to do any Toyota "Oh What A Feelin'" leaps.

First of all, acceleration is just average. As we noted in our prior performance test update, we recorded a 0-60 time of 8.1 seconds. Meh. Our departed long-term Chevrolet Colorado with the V6 was quicker (7.5 seconds) and so is our current long-term F-150 with its turbo 2.7-liter V6 (6.4 seconds). Granted, our F-150 is a different class and price of truck, but nonetheless it sets a certain expectation of performance for a new pickup.

So that's the track-test stuff. Then there's the feel of Tacoma's V6 as you're driving along. There's just not a lot of low-end grunt. You've got to rev it up to really get going. Encounter a hill as you're cruising along and the transmission will almost certainly start downshifting to keep your momentum going as you press in on the gas.

In traffic, this hopping around between fifth and sixth gear can become a bit annoying. Using the ECT button helps, but should you really need to push a button every time you go for a drive?

I can also feel engine vibration through the accelerator pedal. What happened to that renowned 3.5-liter Toyota V6 smoothness? Or what about fuel economy, you might ask? We're averaging 18 mpg so far.

Interestingly, for the 2016 Tacoma consumer reviews posted on Edmunds.com thus far, the evaluation category with the lowest overall rating is Performance.

To be fair, our Colorado's V6 didn't blow us away, either. We described it as "Good, but not Great." That's about how I feel about our Tacoma's V6.

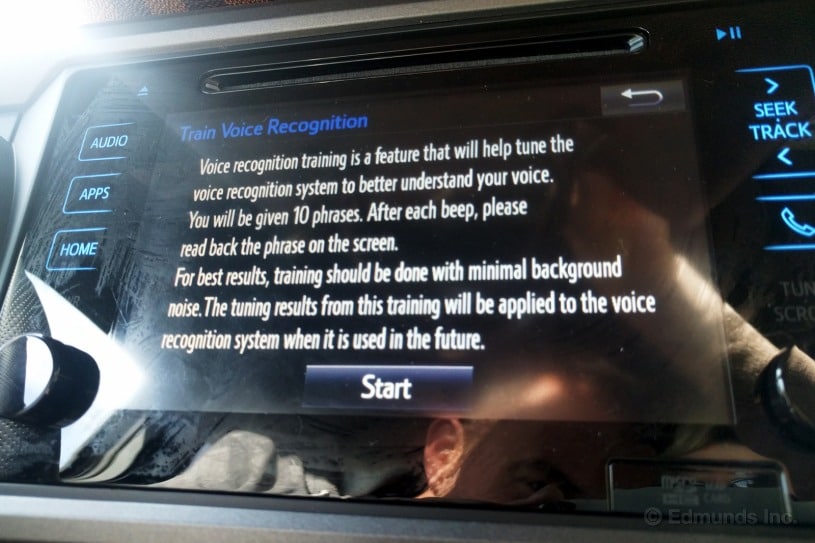

Clunky Voice Control for Those Without Apple Phones

Toyota is the last major automaker with no announced plans to support Android Auto or Apple CarPlay. With this in mind, I was curious to see how the infotainment system in our long-term 2016 Toyota Tacoma handled voice commands.

What happens when you press the button? The first thing I saw on the screen was an option to train the system to recognize my voice. Of course I pressed it.

The screen then displayed a list of sample commands and asked me to read them in a quiet environment. I tried this while idling through a carwash, but the system deemed it too noisy and cancelled the procedure.

I tried it again when I parked at home and documented the process. Below are the prompts the system requested, written as they were displayed.

-

Reserve a table at 8 PM for 4 people at Horseback Steak House.

-

Would you like to go to lunch tomorrow for your birthday?

-

Dial 4 2 5 9 6 8 7 9 0 3.

-

Show what songs I have by the artist Josh Washington.

-

Play all my music in the rock genre.

-

Listen to FM 1 oh 7 point 7.

-

Add a new house number to an address.

-

Select this radio station preset.

-

Choose a city center destination as a new stopover on my route.

-

Can you go to the previous item?

How'd everything work afterwards? Well, the system had no problems recognizing my voice. Yet I was disappointed that it couldn't discern conversational voice commands, like some of the examples it presented during the voice training process.

When you want to enter an address in navigation, for example, you have to go through a stepped process. When you press the voice command button, you say, "Navigation." Then the system prompts you for the next command. You say "Enter address." Then the system asks you to confirm, and so on.

On my phone, I say "Give me directions to [address]," or some variation. My phone even understands more nuanced commands, like "What time does the nearest [business name] close?"

Toyota has a solution to this: Siri Eyes Free, which comes standard on all Tacoma models. Once you pair your Apple phone, pressing and holding the voice command button allows you to make those conversational style commands successfully.

This is great, provided you have an Apple phone. Those with Android phones are out of luck.

In fairness, the infotainment screen reacts quickly to touch-based inputs and has some natural language voice command recognition, like "What's the weather like today?" Still, I'm sure many buyers are hoping for full Android Auto or broader Apple CarPlay support.

Sedona, as you are likely aware, is more than just a current member of the Edmunds long-term fleet. It's also a town in Arizona, one that incidentally was named after the wife of its first postmaster, a man called Theodore Carlton Schnebly. My wife and I went there for vacation last week, accompanied by the long-term 2016 Toyota Tacoma. We left town as auspiciously as possible, taking rock-strewn Schnebly Hill Road (pictured above) to Interstate 17, and found ourselves bursting with impressions when all was said and done.

Here are three that stood out (plus bonus off-road video action!).

1. Brent's Right About the Powertrain

It's all been said, pretty much; I'm just adding my voice to the choir. When I get into a truck with an upgraded motor, I expect some palpable low-end grunt, and the Tacoma V6 disappoints. The new 3.5 doesn't come alive until it surges past 4,000 rpm, which is cool in a Camry but basically the opposite of how truck engines (e.g., the Tacoma's previous 4.0-liter V6) typically deliver their power.

Also, the gearing is almost Corvette-tall — I'm talking 2,000 rpm at 80 mph in 6th gear — so if you want acceleration, you'll need to request a momentous downshift. Even keeping up with freeway traffic requires undue driver attention, since there's no roll-on power in 6th whatsoever. I repeatedly dropped 5-10 mph without realizing it because I wrongly assumed that squeezing the gas gently in 6th was going to do something. And whenever you see a long incline ahead, prepare for a drop to 4th; there's no other way to maintain uphill speed.

The behavior I'm describing here would be acceptable in the base four-cylinder Tacoma, but again, shoppers interested in the upgrade engine will likely want more oomph. Frankly, this truck cries out for a modern fuel-efficient turbocharged engine — you know, the ones with a torque plateau from something like 1,800 rpm to 5,000. That's prime truck territory, and except for the upper reaches, the Tacoma's V6 doesn't have it covered.

2. I Love the Ride

It's remarkably smooth and quiet. Highway speeds are nothing for this truck in terms of refinement; you can have a conversation in normal tones and listen to the radio at normal volume. Pretty cool for such a rough-and-tumble machine. And the off-road suspension is supple and not at all bouncy in civilization — it just rolls uneventfully over any surface. Perfect vehicle if you live in a city full of potholes, to say nothing of its off-road capabilities.

3. It Has Off-Road Capabilities

Oh alright, let's say something about those. As noted, we left Sedona via Schnebly Hill Road, an old dirt track that's in downright nasty shape for much of its 12 miles. This video captures a bit of the flavor, though it's far from the worst section:

I'm no off-road enthusiast, but the Tacoma was obviously in its element here. In 4-Lo, the engine's torque deficiency is not apparent, while the beefy shocks just pogo along cheerfully, no matter how treacherous the terrain appears. This is a true dual-use truck that's equally at home on paved and unpaved terrain.

Give it a motor with some gumption and I just might buy one myself.

March Sees Best- and Worst-Ever Tank Fuel Economy

In March, our long-term 2016 Toyota Tacoma hauled some shrubbery, showed a peculiarity of its keyless entry and drew a mixed review of its powertrain.

The handsome gray pickup was also tasked with considerable road time, racking up some 2,455 miles over the month.

In short, it was a month of highs and lows.

March saw the Tacoma's best-ever single tank fuel economy of 20.6 mpg. This was in turn countered by a 16.0 mpg fill that represents its worst-ever single-tank result. The truck rang in at 18.7 mpg for the month.

In the process, the Tacoma bumped up its lifetime average fuel economy to 18.3 mpg. A relatively good result, but still short of its EPA Combined rating of 20 mpg. Toyota doesn't break out the fuel economy of the TRD Off-Road package separately, though, so it's hard to say just how much of our long-termer's mpg shortfall is attributable to its aerodynamically draggier ride height and knobby tires.

I drove our long-term 2016 Toyota Tacoma for the first time over the weekend. Immediately, I felt like a first-time driver again.

The problem is the Tacoma's brake pedal modulation. It isn't natural, and to an outside observer it can make the Tacoma's driver look like a first-timer. Fellow editor Travis observed it, too. Let's break down the Tacoma's brake pedal action to better describe what it feels like.

Step One: There's some initial pedal travel wherein nothing happens (aka idle stroke). This is typical. Maybe the Tacoma's idle stroke is a hair longer than average. Maybe. In any case, this step isn't where the problem is.

Step Two: Shortly after the idle stroke is an abrupt, nonlinear increase in braking force with little associated increase in effort. This is the first problem with its action.

Instinctively, you back off the pedal a hair to offset this more-than-intended increase in retardation.

Step Three: This brings us to the other problem with the Tacoma's brake modulation — its release characteristic is too aggressive. Ease off the brake pedal a bit and you lose a whole lot (more than expected, anyway) of braking force. Instinctively, you reapply the pedal and you're back at step two.

The upshot of all this is that it's not easy to be smooth in the Tacoma during routine stopping maneuvers around town. Its brake modulation is kinda-sorta workable if you're wearing sneakers (which offer more sensitivity) but significantly more difficult in boots. I found myself having to think about my braking action rather than simply intuiting it, and yet still bobbing the truck's nose more than I'd liked.

For those keeping track at home, the Colorado is clearly better than the Tacoma in the brake modulation category.

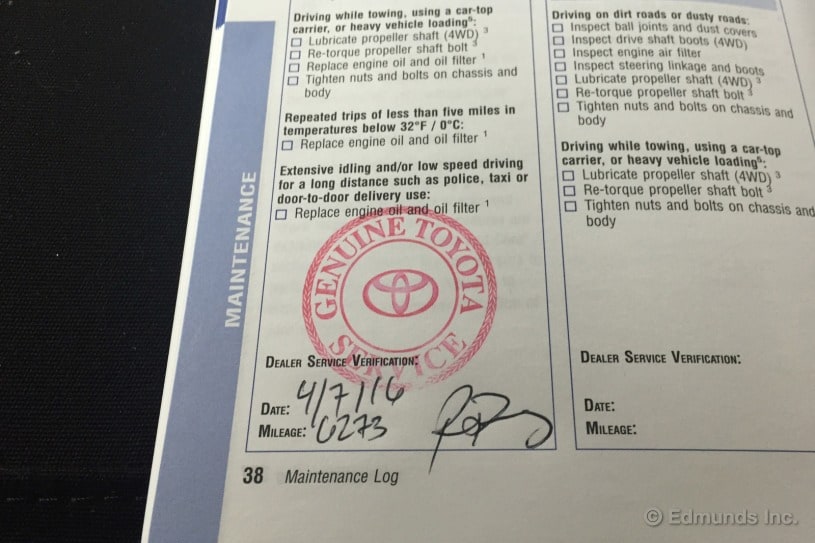

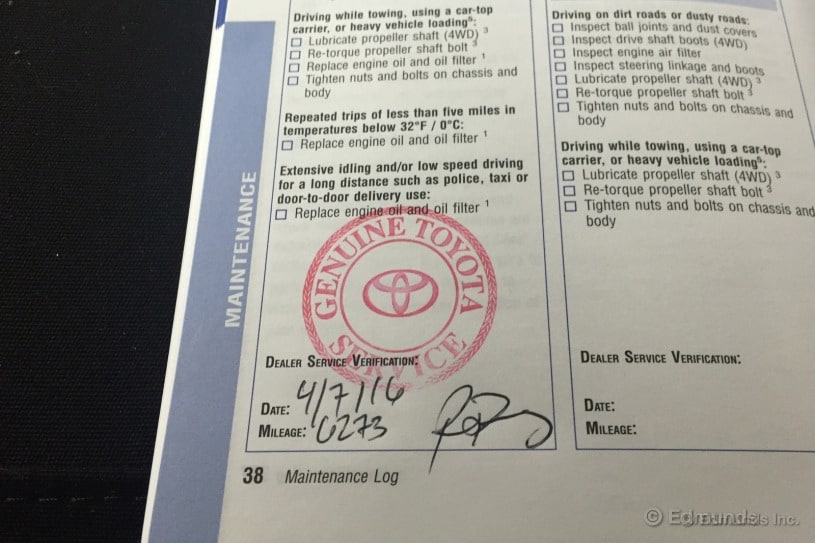

Our long-term 2016 Toyota Tacoma calls for its first service at 5,000 miles. It's a relatively simple service compared to some other vehicles in our fleet.

The maintenance log lists the following:

- - Check installation of the driver's floor mat

- - Inspect and adjust all fluid levels

- - Inspect wiper blades

- - Rotate tires

- - Visually inspect brake linings/drums and brake pads/discs

All in all, the tire rotation seems to be the most labor intensive service. Additional service is recommended if you drive frequently on dirt roads or dusty roads, tow often, or a few other situations that don't apply to our truck. No oil change is called for in the first service unless the truck idles extensively or is driven at low speeds in freezing weather.

With just the simple service, I hoped we could get the Tacoma in and out of the dealer in a few hours.

I took the Tacoma to Toyota Santa Monica, just a few miles from our office. I managed to get there right as the doors opened, so there was no wait for a service advisor. The line was backed up to the street by the time I finished getting checked in.

I told the advisor I wanted the 5,000-mile service and asked for an estimate. He looked at the line and told me two hours or less. I received a call fewer than 90 minutes later letting me know the truck was ready.

As I was going over the invoice, I noticed that the dealer performed an oil change despite the Tacoma not needing one. This would have bothered me if I was being charged, but the Tacoma is covered by Toyota’s no-cost maintenance. I’m not going to complain about a free oil change.

Total cost - $0

Total days out of service - Zero

The bed of a pickup truck is what makes a pickup truck a pickup truck. On that basis, the 2016 Toyota Tacoma is a pickup truck among pickup trucks, or words to that effect.

There's a lot to like back here, is what I'm saying, and much of it is standard. All of it comes gratis on all Tacomas except for one item that is exclusive to the TRD and above.

Let's take a brief tour of eight things that make a Tacoma's bed pretty great.

All Toyota Tacomas of any stripe get the following:

1) Composite bed — this has been a Tacoma feature for some time, and it works. There's no paint to rub off, no bedliner to buy, no protective textured coating to apply. The load face of the tailgate matches, too. We liked the Line-X spray-in bedliners we added to our Colorado, Ram 1500 and Ford F-150, but products like those still represent an extra expense that Tacoma buyers can avoid.

2) Protective fender and tailgate toppers — the upper edges of a bed are subject to all sorts of dings and dents during the course of loading and hauling, but the Tacoma literally has this covered. Not necessarily unique these days, but part of a complete package.

3) LED bed lighting — you can't see it here, but the center high-mount stop lamp (aka CHMSL or third brake light) at the top of the cab has LED lights built into the same housing. Open a door or flick on a switch in the cab and you've got light.

4) Squared-off fender wells — the fender tops are flat, and they line up with a molded ledge that goes all the way to the back. A pair of 2x6 notches are provided, and all of this makes it possible to fit a stable platform with room for sub-floor storage.

5) Fixed tie-down points — there are four of them, which is fairly standard. The stout front pair are ready to secure heavy items up against the cab while the rear pair are d-rings positioned low down where they're better able to secure the corners of a tarp.

6) Deck rails with four moveable cleats — these give you lots of options to tie down just about anything, anywhere. Use your imagination.

7) In-bed storage bins — these storage bins protrude into the hollow between bed and fender where they won't intrude into the cargo area. They're just about the right size for things like gloves, ratchet straps, bungee cords or some rope. They'll even hold the slide-out hitch ball that fits in your trailer hitch. You'll find one on each side of the bed. They don't lock, but in our experience they're not a likely theft target.

There is but one item that is not standard across the board. It comes standard on TRD and above, but is not available on the SR or SR5:

8) Power outlet — This 120-volt, 400-watt outlet has the capacity necessary to power cordless drill recharging equipment, work lights or a portable camping fridge. The passenger-side storage bin shrinks to make room, but it's a good trade.

Looking at the Chevrolet Colorado and GMC Canyon, neither comes standard with #1, #4, #6, #7 or #8. An extra-cost accessory a tie-down system is available and GM offers an optional spray-in bedliner, but now we're talking real money. As for the rest, it's simply not there.

Our 2016 Toyota Tacoma is a pickup. Of course a mountain bike will fit. Duh. It's more a question of whether or not the tailgate will close without the need to load the bike in diagonally.

Mostly, I needed an excuse to share this picture of my bike's 29er front tire leaning up against the Taco's 31-inch off-road tire. I don't know why it makes me grin, it just does.

For the record, the tailgate will close with an XL 29er mountain bike loaded in straight. You'll need to remove the front wheel, but that's pretty much standard procedure. And the Tacoma's bed looks ripe for a fork clamp mounted along the upper forward lip of the bed. It looks like three of them could readily fit in there with judicious use of the numerous available tie-down options to keep the handlebars and pedals from getting entangled.

I hate to stop for gas. Hate it. Takes time. Costs money. Yada yada. So I avoid it. Wait til the last minute. Or mile. Drives my wife crazy. My kids too.

And that's why I like cars and trucks that don't just suggest you go for some go-go juice but get aggressive about it. I like cars with bongs and beeps. Cars with bright lights and big messages. I like cars that grab me by the throat and scream STOP FOR GAS STUPID!

I like our long-term 2016 Toyota Tacoma.

With 21 miles of range remaining, the Tacoma's instrument cluster began to grab and scream. On came a very bright idiot light, shaped like a gas pump, beside the truck's gas gauge, along with a complete bright orange takeover of its center information screen and an audible bong. After a few more miles the pressure was just too much, I gave in.

At the pump the truck took 18.022 gallons of 87 octane. I had driven 325.5 mile on the previous tank for an average of 18.1 mpg.

Thing is our Tacoma has a 21.1 gallon tank, which means there were still a few gallons left in the tank when the truck began to bark.

I'll remember that next time.

Our 2016 Toyota Tacoma is getting a healthy amount of miles on its odometer, so this month we brought it in for its first scheduled service. It was just a check up for the most part as an oil change wasn't even part of the suggested maintenance.

Apart from that quick trip, our Tacoma hauled a few bikes in its versatile bed and annoyed yet another editor with its touchy brakes. A heavy dose of urban driving also drove its overall fuel economy number down to 18.3 mpg overall. A big chunk of that was due to its worst overall tank yet which came in a 15.7 mpg.

Worst Fill MPG: 15.7

Best Fill MPG: 19.8

Average Lifetime MPG: 18.3

EPA MPG Rating: 20 Combined (18 City/23 Highway)

Best Range: 349.0 miles

Current Odometer: 7,738

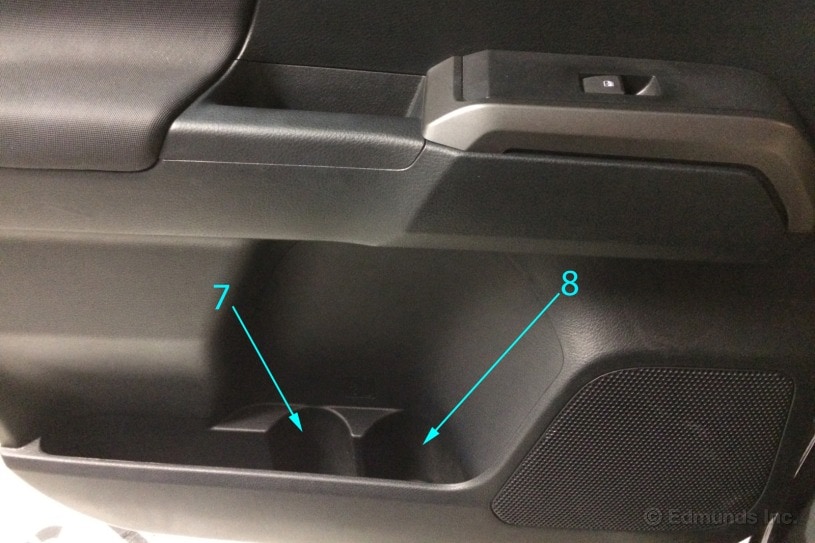

When my daughter slid into the back seat of the 2016 Toyota Tacoma the first thing she did is request a Bluetooth connection. Once that was established, she proceeded to complain about the lack of legroom. Is it really that tight in back of the Tacoma?

Turns out, the numbers back up her complaints. Compared to the Chevrolet Colorado, the Tacoma has considerably less legroom. We're talking over 3 inches here, which is quite big in a midsize truck. Even the ancient Nissan Frontier has more legroom than the Tacoma.

In some other dimensions, the Tacoma is more spacious. It has the same amount of headroom as the Colorado and far more shoulder room (58.9 to 56.1). When it comes to hip room, the Tacoma comes out ahead, too.

She also noted that there aren't any vents for the rear passengers. Given the overall size of the cabin, it's not that surprising that Toyota didn't bother with separate registers for the back seats.

Once the front seats were moved forward far enough to give her adequate legroom, there were no further complaints. I'll take that as a sign that the seats themselves are sufficiently comfortable.

Here it is fast and hard. I loved our long-term Chevy Colorado and up to this point I've hated our long-term 2016 Toyota Tacoma. I've hated the Taco's weird arms-out seating position, its touchy brakes and its lazy throttle response.

But here's the thing, I was wrong.

Not about the Colorado, great truck. I was wrong about the Tacoma. Like me, it's an acquired taste.

At first blush the Tacoma can be a bit off putting. It's kinda in your face. Maybe a bit too aggressive. Emotional even. It doesn't seem to want to conform to you or the way other automakers are doing it. It comes off like it thinks it knows better and at first blush you want to kick it to the curb for its arrogance.

But the truck doesn't mean to offend. You just have to give it chance. Listen to it. Yes, it's a bit heavy handed in the way it approaches the conversation, but you're better off listening to what it's saying instead of how it may be said. Otherwise you might misinterpret the message.

I know this because I got to know the Tacoma better over the last few weeks and it's one helluva truck. There's a reason these things are so popular and with time, and miles, the Tacoma and I have bonded. We've gone from haters to BFFs, and it just took a few hundred miles of togetherness.

After a solid few weeks behind the wheel I no longer have issues with the Toyota's seating position or its brakes. And I've found other subsystems to praise, like its six-speed automatic transmission, which really feels good and responds well when you manually manipulate its gated shifter, and its long-travel off-road capable suspension, which soaks up the paved world better than most luxury sedans.

Being wrong and jumping to conclusions are just part of life, but I'm glad I gave the Tacoma another chance. It deserved it.

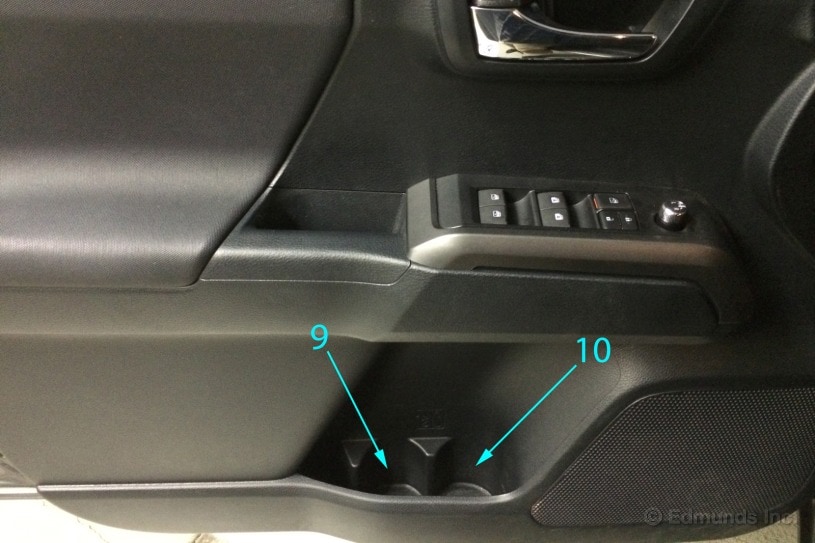

Whether you're out kicking up sand in the desert, climbing up mountain trails, or swimming through a sea of shopping mall traffic, it's important to be well-hydrated while driving your 2016 Toyota Tacoma. Or at least that's the subliminal message I received poking around the cabin the other day.

Pop quiz: Can you correctly guess the total number of cup holders in the Tacoma's cabin?

Three? Nope.

Five? Uh-uh.

Eight??

If you guessed 14 — 14! — then pat yourself on the back. I'll even award credit to those who guessed 13, because the square-shaped holder just ahead of the center armrest could be up for debate.

For the record, I have used that questionable square space to hold a roundish Starbucks grande cup prior to this writing. And there are such things as square-bottom drinking containers, as pictured below.

Assuming a full five-passenger load, there are a total of 2.8 beverage spots per person, which is 0.8 more than any business-class airplane seat I've experienced.

As a proponent of hydration and someone that almost always carries a bottle of water or two with them, I fully endorse the Tacoma's surfeit of drink storage options.

It isn't perfect, but I generally like the EnTune touchscreen audio system in our 2016 Toyota Tacoma pickup. It's clearly better than the touchscreen systems that the Honda Pilot and Civic use, and one of the main reasons boils down to a feature that the Honda systems lack: physical volume and tune knobs.

But Toyota's knobs are smallish, a bit slippery and — worst of all — they don't project far enough away from the touch-sensitive radio faceplate. In the course of using them your fingers skim the surface of the radio, which often leads to false contact with nearby touch-sensitive areas — especially when a moving car is jostling around. On the volume side, you might accidentally trip the number-six preset. On the tuning side, you'll trigger the fader and balance sub-menu.

This weekend I had an idea that's more of a proof-of-concept design change proposal than a permanent solution. It's a suggestion I'd give to the Toyota radio design team if I ever got five minutes of their time. And there's much to be gained because this is not just a Tacoma issue. Our Prius and Mirai have the same knobs, along with every single current Toyota that's fitted with the EnTune touchscreen audio system.

As you may know, radio knobs usually come off by applying firm and steady pressure, a reversal of how they were installed at the factory to begin with. My plan was simple and probably obvious: pop them free and pull them a bit farther away from the radio faceplate to see it that made any difference.

There was a strong detent to overcome, but after a bit of uncertain wincing I got them moving without breaking anything. As I'd hoped, they're indexed to a stem that extends from the radio and engages the knobs for something like a half-inch. I had room to experiment.

The sweet spot seems to be somewhere between one-eighth and three-sixteenths of an inch (about 4 millimeters) farther out than the standard position. That may not sound like much but it results in a dramatic improvement.

The knobs are much easier to grab onto and use, and I almost no longer care that they're not knurled. Look at the reflection of my fingertips in the before and after pictures and you'll see they're no longer close to brushing up against the glass.

As much as I'd like to, I can't really leave them like this. There's no detent to hold them in this altered position, so an enthusiastic car detailer could knock them free.

What Toyota needs to do is either make the knobs thicker or increase the length of the part that sticks out the back and engages the shaft. Better still, they should do a little of both and add 2 millimeters to each dimension.

A couple of the new trees in my front yard are growing quickly, and I needed to re-stake them. So I pointed our 2016 Toyota Tacoma pickup toward the nearest Home Depot for a pair of tree stakes.

The rack they were stacked on said they were 8 feet long, which I should have expected, but didn't. Our crew cab Tacoma rides on the standard wheelbase, which means it has a 5-foot bed — 60.5 inches, if you want to split hairs. My new stakes were destined to hang out more than 2 feet.

I first loaded them in straight. It could have worked, but I wasn't a fan. Then I put them in diagonally, which was better from a hanging-out-the-back standpoint but introduced a side overhang that had the potential to snag a lane-splitting motorcyclist.

Then I had a third idea, but it wasn't perfect, either. I went with it anyway.

I opened the pass-through window and let them poke into the cab. Stupid, right?

It's not that dumb. I was alone. The center-mounted window would force them to point away from my delicate cranium if I jammed the butt ends into the rear corner of the bed on the driver's side.

But this would only work if they were restrained from moving, and I had a strap for that.

I folded the rear seatback and found a couple of loops — one for the seatback itself, the other for a child restraint. Each would be robust enough so long as I didn't ratchet the strap very tight. I figured the friction between the rough wood and the coarse webbing would do the job if the strap was merely snug.

Besides, this would only have to work for three miles.

The Tacoma's long bed is just over 6 feet long — 73.7 inches, to be exact. But putting that bed behind a crew cab would force me to deal with the reduced maneuverability and diminished off-road clearance of a long-wheelbase truck. No thanks.

There is another way: buy the extended cab and get the utility of the longer bed on the more maneuverable short wheelbase. I could go for that.

When an editor begins rating cars for Edmunds.com, we are trained to take note of the smallest shortcomings, whether that be an errant noise in the cabin, an unsightly panel gap or poorly engineered cup holder. We do this not to be annoying nitpickers, but rather to identify things that could possibly be irritants or cause issues for a long-term car owner down the road.

On a recent mini road trip, I discovered something about our 2016 Toyota Tacoma that would certainly cause me perpetual discomfort if I were the owner. Surprisingly, it's not the Tacoma's brakes.

You may have been wondering what the heck I was trying to capture in the image above — it is macro view of the texture of our Tacoma's door armrest. This is important because it makes up 50 percent of my issue.

The other half of the issue is a complete lack of padding underneath this layer, which sits on top the hard plastic panel of the door. These two factors combine to make for the most uncomfortable armrest I've experienced in a modern vehicle.

(caption: Pressing down hard on the armrest to show how much compliance it has.)

Perhaps it's due to the way I hold the steering wheel during long-distance cruising — I generally have my left hand on the wheel, resting an elbow on the outer armrest — but the hard and bumpy texture is about as comfortable as concrete. If one of the two factors of this evil armrest were changed, it would solve the problem. Take the middle armrest as an example. There is still virtually zero padding, but the texture is smooth and elbow-friendly, rather than pointlessly bumpy.

If you're not the short-sleeve wearing type, have thicker elbow skin or less sensitive nerves, this may be of zero concern to you. But for me this wouldn't fly, especially if I were spending over $35,000 of my own money. Unfortunately there are no interior options for the TRD Off Road trim that would remedy this. I'd have to move up to the Limited trim for a different interior and forego the cool TRD bits.

Despite a decade in the biz, I haven't exactly spent a lot of it off road. Perhaps it's because I don't like driving slowly, perhaps it's because I don't like getting dirty. Either way, getting a chance to take a 2016 Toyota Tacoma off road is a worthwhile experience, as unlike other trucks, its modus operandi seems to be venturing beyond where the pavement runs out. This is especially true of our TRD Off-Road trim level (shared with the test truck I also drove above) that benefits from a variety of features supposedly designed to help out experts and novices alike.

As we reported in our long-termer's introduction, the TRD Off-Road includes Bilstein shocks, a lockable rear differential and Crawl Control, which is essentially a low-speed cruise control that in conjunction with the 4x4 system's low range automatically applies the throttle to get you through low traction situations.

Frankly, though, it would have to be an especially low-traction situation. The trail I was on, with steep inclines covered in dusty dirt and rocks, really didn't require it. I was more than capable of operating the throttle, which regardless of where you're driving, is shockingly responsive for a Toyota product. That goes for the brakes and steering as well — the Tacoma really doesn't feel like it comes from the same company that brings you the Camry, Highlander and even the Tundra.

Hill descent control is also included, but the system seems less sophisticated than those in other vehicles I've experienced. The automatic brake grabbing is so uncouthly loud it sounds like small automatic weapons fire is emanating from somewhere underneath the truck.

In other words, on the trails I ventured — which I would deem to be what a typical owner may come across — these automated technologies weren't really needed. And really, if you don't actually want to drive off road, why even buy a Tacoma TRD Off-Road? (OK, so it does look cool, especially in the dirt-colored one pictured).

On the other hand, our Tacoma also includes Multi-terrain Select, which allows you to select from a variety of surface types that the truck then sets itself to best tackle. 4WD Low must be applied to use it. Since I was on rocks and dirt, I set it to Rocks and Dirt. For novices I think this is a worthwhile technology since one may not know exactly how much to alter their usual throttle inputs from not just road to trail, but different trail surfaces. If nothing else, it grants an added degree of confidence.

Now, I actually got a chance to drive the Tacoma back-to-back with the most off-roady version of a GMC Canyon (with its front aero dam removed). Whereas the GMC was perfectly capable of tackling the same terrain, it felt like a fish out of water. It got the job done, but I can't imagine having much fun while doing it, or even stepping up to something more severe. The Tacoma, on the other hand, seemed to be right at home, with a poise and capability that's readily apparent — even to those who are happier on the well-beaten path.

I'm not all that fond of the driver seating position in our 2016 Toyota Tacoma. Relative to many other vehicles, the Tacoma's seats are mounted closer to the floor. I'm 5-foot 10-inches tall, but my legs are proportionally long. So in order to get enough thigh support and have my feet in the right places for the pedals, I need to slide the driver seat back. But then my arms are extended out more than I prefer to reach the steering wheel.

Our Tacoma isn't super easy to get in or out of, either. The step-up height is elevated (all rear-drive Tacomas have the same stance as the 4WD versions this year) and the steering wheel can get in the way when I'm moving my legs in and out.

The low seat has been a Tacoma trait for a while now, though apparently Toyota's engineers raised the front seat height for this new generation. I've looked over some Edmunds.com 2016 Tacoma consumer reviews. Some people have complained about what I've stated above, but there are just as many reviews with five stars for comfort. Plus, it's probably something you just get used to over time, as the multitudes of happy Tacoma owners would attest to.

I'm not necessarily uncomfortable. The seat itself is fine. But if you're shopping for a midsize pickup and also looking at the Chevrolet Colorado (and GMC Canyon twin), pay attention to driver seat comfort/positioning and the ease of getting in and out. In my experience, the GM trucks are superior trucks in this regard.

Fuel Economy Update for May - Show Me the MPG

May was a fairly quiet month for our 2016 Toyota Tacoma. We added about 1,000 miles, and much of that was amassed during commutes to and from our Santa Monica, California, offices. The good news is that the city-heavy driving didn't impact our lifetime fuel economy much. The bad news is that our truck is still underperforming compared to what the EPA says to expect.

For the month, we averaged 16.8 mpg. That's below what the EPA says to expect for pure city driving (18 mpg). Lifetime, we dropped from 18.3 mpg last month to 18.2 now. Nor have we bested Josh Sadlier's best tank of 20.6 mpg that he observed during his drive to Sedona back in March.

I do like our Tacoma, but the expectation of getting dramatically better fuel economy than a full-size truck probably isn't going to be realized during this test.

Worst Fill MPG: 15.7

Best Fill MPG: 20.6

Average Lifetime MPG: 18.2

EPA MPG Rating: 20 Combined (18 City/23 Highway)

Best Range: 349.0 miles

Current Odometer: 8,823

More Comfortable on the Highway Than the Old Tacoma, But Still Not Great

It's interesting to think about where our 2016 Toyota Tacoma ranks for comfort and quietness while driving on the highway. If you were to compare it to a BMW 340i, you'd probably come away thinking "Jeez, this Tacoma is really bouncy and noisy!" But if you were to compare it to a soft-top Jeep Wrangler, you'd probably think "Hey, this isn't so bad. I could drive to Alaska in this thing!"

You'd also find it more pleasing to drive than the previous-generation Tacoma.

In our reviews and ratings of the previous-gen Tacoma from a few years ago (it technically ran from 2005-'15), we noted drawbacks of excessive wind noise, a loud engine, uncomfortable seating and a rough-riding suspension on some models.

I've driven our Tacoma a couple times now for some extended highway drives of about 250 miles. The good news is that I haven't been uncomfortable. The driver seat is fine, though you could still point to the driving position and hard door armrest as potential drawbacks. Wind, road and engine noise are noticeable, but not dramatically so. And for a pickup with an off-road suspension, our Tacoma TRD Off-Road rides respectably well over bumps and broken pavement.

It's about what you'd expect for a pickup. Still, I can't help but think of other pickups I've driven that seemed like they could keep me comfortable for days on end. Our long-term Ford F-150 and Ram 1500 were like that. They could consistently go 500 miles between fill-ups, too. I recently got our best range in our Tacoma, and that was just 351 miles from a full tank of gas. Oh, and there's the Tacoma's V6 and six-speed transmission combo, too, which I previously noted for its lack of low-end torque and overly shifty behavior when going over hills.

In our Tacoma's defense, it's a little unfair to compare it to those more expensive full-size trucks. Against the ancient Nissan Frontier, no question, the Tacoma's more comfortable for long drives. Compared to the Chevrolet Colorado? For the purpose of highway driving, I prefer the Colorado seats, driving position and V6/transmission. I suspect the ride quality is a little stiffer than the Tacoma's, though.

I do like our Tacoma. But for long-distance comfort, there's still room for improvement.

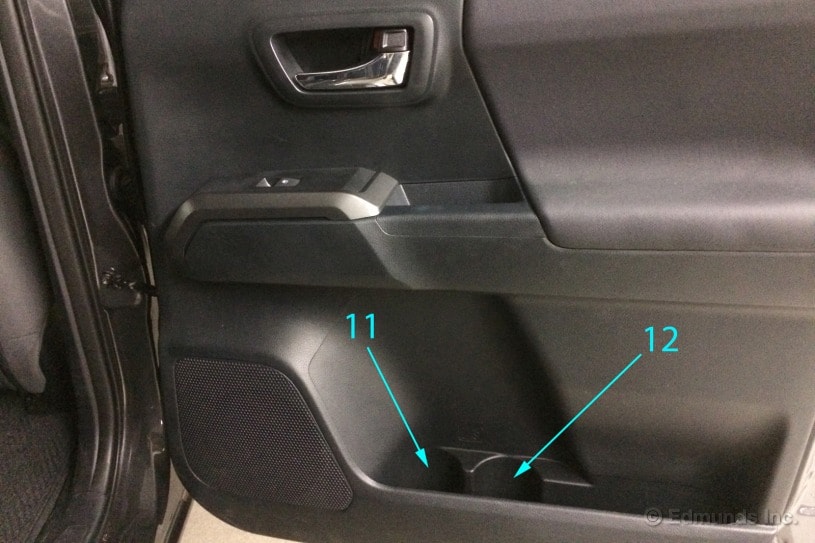

It isn't large (OK, it's large compared to a Fiat 500 or a first-gen Taco truck, but it's not as big as a Tundra) but our long-term 2016 Toyota Tacoma has a few storage tricks up its sleeve. Specifically, the rear seats have these useful little cubbies behind each seat. Just pull the strap on the seat, the seat leans forward and there are hard, plastic storage areas.

Dan has already talked about how useful the seats are for maximizing cargo capacity when you fold the bottoms up and pull the back of the seat forward, but the way I see it, there are other uses as well. Put your expensive drill or your nice sawzall back there and it'll be away from the eyes of prying five-finger-discount enthusiasts. Plus, you still get to use the rear seats. It might not offer as much space as some of the full size trucks we've tested, but Toyota seems to be making the most of limited real estate.

We added nearly 1,500 miles to our 2016 Toyota Tacoma in June, much of it urban and suburban commuting. We're a little soft in southern California, and no one wants to go out and four-wheel during a spell of heat waves like we had recently (although James got out and chopped it up on the trail in a truck identical to ours), so the Tacoma continues to suffer the indignity of too many pavement miles.

But we managed to set a new range record in June, Brent beating the previous mark by a couple of miles. Best range now sits at 351.0 miles. The Tacoma also returned 19.8 mpg on that particular tank, which is just 0.8 of our current best mpg. Over five fill-ups, we averaged 18.2 mpg for the month.

None of it was enough to move the needle on our lifetime mpg. In fact, we actually lost 0.1 mpg. Nearly 10,000 miles into our test now, it's hard to see how we'll improve on that number.

Worst Fill MPG: 15.7

Best Fill MPG: 20.6

Average Lifetime MPG: 18.1

EPA MPG Rating: 20 Combined (18 City/23 Highway)

Best Range: 351.0 miles

Current Odometer: 9,901

I carpooled home with Dan Frio yesterday. He drove us to his house at which point I left to take our 2016 Toyota Tacoma back to my place. Shortly after we parted ways the fuel light came on, so I found the nearest gas station. I was 10 miles from Casa de Frio.

There was nothing remarkable about the fuel stop, yet. I shut off the truck, filled up, started the truck again and merged onto the freeway. My phone rang, "Hey, it's Dan. Is the truck still running? Don't turn it off. I just found the key in my pocket."

I told him about the gas station. We laughed, mine nervous, and decided to meet at my house for the key hand-off. Safely in my driveway I turned the Tacoma off. And then I turned it on and off again four more times. It worked perfectly.

Outside of the car I slid my thumb across the driver door handle to try activating the keyless door lock. A loud chime alerted me that the key was still detected in the vehicle. I unpacked my gear and took it into the house. When I walked back out to the Tacoma and tried to start it again there was "no key detected."

Just then the hero of this story arrived on my curb. Dan passed me the key out of his car window and order was restored. Well, that was until I again tried to lock the door using the keyless feature. It alerted me that the key was still detected inside the vehicle. Except it was in my pocket.

Let's see what the dealer has to say about it.

When work dictated that I bring our 2016 Toyota Tacoma to the High Desert, north of Mojave, I did not argue. I'd been wanting to sample our Tacoma in a more appropriate environment ever since it showed up in our garage. And because I could, I strapped my 1976 Yamaha DT400 into the bed and took it along for the ride.

By the end of the day, I'd learned that one of these things has good low-end grunt and is light on its feet but generally awful, while the other is a little high-strung and unsurprisingly capable but has terrible brakes.

Place your bets.

The Yamaha? Yeah, it's generally awful. While the motor does offer good low-end power (kind of surprising for a two-stroke), and its light weight and less-than-powerful brakes do it a lot of favors off-road, the vintage no-travel suspension ruins its rideability on anything other than faster, hard-packed trails. But it's from 1976 and not a full dirtbike, so that's its excuse. Also, I suck at riding a bike — that's my excuse.

As for the Toyota, it does everything pretty well off-road except for the one thing it doesn't do well on-road, and that's brake smoothly. Such is the confidence you get from driving the Tacoma, with its exceptionally well-sorted suspension, good steering and manageable size, that you can't help but want to get all Ivan Stewart and hustle this thing along. But the brake pedal just doesn't work the same way as the long-travel throttle. The stroke is short and sharp, so when you try to brush the brakes and scrub off a little speed, it's easy to get more braking power than you asked for. What Jay talked about when driving the Tacoma on the street is only magnified in the dirt, where the brakes continually threaten to give you understeer right when you want it the least.