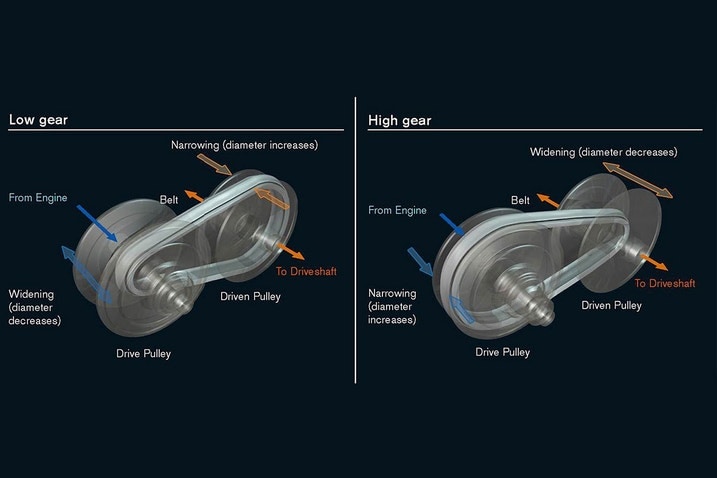

A CVT builds on this concept, but it differs from a traditional automatic transmission in that it doesn’t have gears that provide "steps" between low- and high-speed operation. Instead, the majority of CVTs work via a pair of variable-diameter, cone-shaped pulleys connected by a steel or composite belt.

Although there are several variations on the CVT theme, in most passenger cars the halves of each pulley are aligned with the pointed ends of the cones touching. These form a V-shaped groove in which the connecting belt rides. One side of the pulley is fixed, and the other side is movable, actuated by a hydraulic cylinder. The cylinder can increase or decrease the amount of space between the two sides of the pulley. This design allows the belt to ride lower or higher along the walls of the pulley depending on driving conditions, thereby changing the "gear" ratio.

The stepless nature of its design is the CVT's biggest advantage for automotive engineers. Because of it, a CVT can work to keep an engine in its optimum power range, increasing efficiency and fuel mileage by delivering an infinite number of smooth transitions from low to high. And it's this infinite variability that, according to the EPA, can boost a passenger car's fuel economy by about 6%.

Because continuously variable transmissions differ substantially from conventional automatics and dual-clutch transmissions, they require fluids that are designed to meet the specific demands of CVTs.

Unlike traditional automatic transmission fluids, CVT fluids are developed to enable the smooth operation of the belt and pulley system within a continuously variable transmission. The CVT fluid’s primary role is to provide lubrication for transmission components like the pulleys and belt since they are subjected to constant pressure and friction during operation. CVT fluid formulas also often include friction modifiers that ensure the transmission belt is properly engaged.

CVT fluid is also designed to help dissipate heat because excess heat can damage CVT belts and other vital components. Using the appropriate fluid will help the transmission maintain the correct operating temperature range and extend its service life. To determine which type of fluid to use with the continuously variable transmission in your vehicle, consult the owner’s manual.

The CVT's value lies not only in its efficiency but also in its simplicity. It has very few components compared to a traditional automatic transmission, which can contain a mind-boggling array of hundreds of moving parts. Typical CVT components include a high-strength belt, a hydraulically operated driving pulley, a mechanical torque-sensing pulley, and a collection of microprocessors and sensors.

Because of this design simplicity, CVTs offer a number of advantages over traditional automatic transmissions. In addition to improved fuel economy and reduced manufacturing costs, they offer steady acceleration, smooth operation, and the ability to seamlessly adapt to varying road conditions and power demands as needed.

However, CVTs also have some drawbacks. For some drivers, the disconnect between the pressure being applied to the accelerator and engine speed can be unsettling, particularly in applications where the CVT has not been designed to “resolve” upper rpm power demands with a simulated upshift that brings the engine’s rpm back down in a stepped manner that’s similar to a conventional automatic. This so-called rubber band effect is caused by the CVT keeping the engine in the most efficient powerband range at all times, even when that rpm range is higher or lower than the accelerator pedal's position might indicate. In addition, belt-driven CVTs often provide less torque than a traditional automatic (although this is improving all the time), and transmitting power by friction can cause greater wear on belts and other components.

Still, in the right applications and in most circumstances, a CVT's advantages outweigh its disadvantages, so it's easy to understand why manufacturers of high-efficiency vehicles often incorporate CVT technology into their drivetrains. You can expect to see more CVTs in the coming years as technological advances widen their functionality and automakers continue to strive for improved fuel economy.

While automakers like Nissan and Ford had some reliability issues with their early CVT designs, these problems have largely been resolved thanks to years of ongoing development. Provided that the maintenance schedule outlined in the vehicle’s owner’s manual has been followed, you can expect many years of hassle-free operation from a CVT today.

Because regular maintenance is so vital to a CVT’s longevity, it’s important to verify that previous owners also adhered to the manufacturer’s recommended service schedule if you’re considering buying a used vehicle that’s equipped with a CVT.

As with conventional automatic transmissions, the components in a continuously variable transmission will eventually wear out over time with use. And much like a traditional automatic, repairing or replacing a CVT can be a costly proposition. While CVTs can be rebuilt, dealers and transmission shops will often recommend replacing the unit due to the complexity of the repair and the limited availability of components from both automakers and third-party vendors. In some cases, the cost of replacing a continuously variable transmission can exceed the vehicle's value, so it might not be worth the expense in an older, high-mileage vehicle.

Many manufacturers offer models that come with CVTs. Some of the most popular models with CVTs include the front-wheel-drive Buick Encore GX and Chevrolet Trailblazer, the Honda Civic and Accord, the Kia K4 and Soul, the Nissan Altima, the Subaru Crosstrek and Forester, and the Toyota Corolla and RAV4. Ford, Honda, Toyota and other manufacturers also offer an electric continuously variable transmission (eCVT) in their hybrid products, but that technology uses electric motors and planetary gearsets instead of the aforementioned pulley-and-belt layout.

Surprisingly, the CVT, isn't a very new idea. As early as the 16th century, Leonardo da Vinci sketched a drawing that appears to describe the technology. An early version of the CVT was a component on the first automobile, patented by Karl Benz in 1886. Although these transmissions fell out of favor for automobiles quite early, they've been widely used for more than a century in industrial applications (drill presses and lathes, for instance) and more recently in personal watercraft, scooters and snowmobiles.

The CVT came back to the modern automobile as manufacturers began looking for ways to increase fuel efficiency. Subaru introduced the first modern automotive CVT in the U.S. on the subcompact Justy for the 1989 model year. Other automakers began developing their own CVTs throughout the 1990s.

Since then, the introduction of improved materials — such as high-strength belts, advanced hydraulics and high-speed sensors — has been responsible for the CVT's growth in the automotive arena. New materials and other innovations have made it possible to design small, relatively inexpensive CVTs that reliably deliver valuable fuel efficiency improvements.