2009 Ford Flex: What's It Like to Live With?

Read the latest updates in our long-term road test of the 2009 Ford Flex as our editors live with this car for a year.

What do you want to know about?

- Introduction

- Crunch-Crunch, Drip-Drip

- Big Scion. Hallelujah.

- Sir Flex a lot

- ROAD TRIP!

- Road Trip Part 1

- Road Trip Part II

- Road Trip Part III, The midwest

- Road Trip part III, made it.

- Road Trip Part IV, Best Road Trip Car Ever?

- Road Trip, On refrigeration and hitting the wall

- Road Trip Conclusion by the Numbers

- Sometimes the Truth Hearse

- Highway Wind And Road Noise

- D, L And Nothing Else

- Third-Row Seat

- Flexin' Its IKEA Muscle

- Fuel Economy Update

- Not Enough Power To Suck

- 2009 Ford Flex Limited is Worth a Test Drive

- Headrests From Hell

- Ford's Finest?

- Oregon Bound

- Last Minute Panic

- Oregon Day 1, Identity Crisis?

- Oregon Day 2, Eureka!

- Oregon Day 3, Stormy Weather

- Oregon Day 4, Seagull Approved

- Oregon Day 5, Easy Access

- Oregon Day 6, Snow Day!

- Oregon Day 8, Making our Escape

- Oregon Day 9, Home at Last

- Oregon Wrap-Up

- High Quality So Far

- 2009 Ford Flex Annoying Chimes Edition

- Our Favorite Caption

- You Write the Caption

- We Got Weather

- Hit Me Baby One More Time

- Oil Change Required

- Flying First Class

- Oil Change

- 20,000 Miles

- 14-year-old Boy Approved

- Excellent Rear Visibility

- Best Bluetooth Award

- Country Squire Package

- Oh No! It Won't Come Off!

- Separated At Birth

- Our Favorite Caption

- You Write the Caption

- Downshift Already!

- Transporting Billy

- Conestoga Wagon With Tinted Windows

- I Wanna Hold Your Hand

- Cramming It Full

- It's easy

- Part 2 of What's It Like to Work at Inside Line?

- Funk Masters Flex

- Another Rough Day At The Office

- "There's a Little Ford GT in Every Flex We Build"

- 25,000 Miles

- Tired

- Driving the Stink Out of It

- Maneuverable

- Dealer FAIL

- Fiesta At My Place

- Open Thread

- Picture Perfect

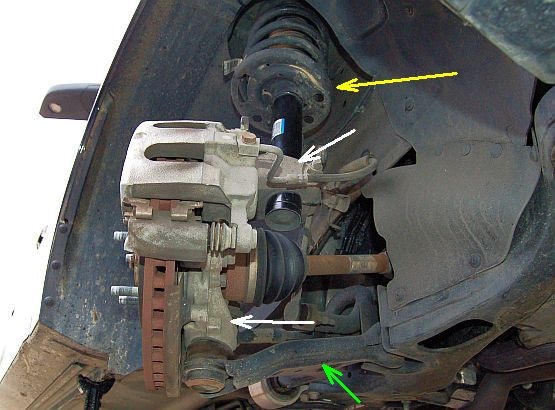

- Suspension Walkaround

- Bigger in Person

- My Winter Olympic Ride?

- Easy Tech

- True to the Concept?

- Broken and Disconnected

- Cruise Interface Still Terrible

- Broken Interior Trim

- Where Are The Auto Windows?

- Interior by the Gap

- Sunroof Shade Drama Part II

- Power Tailgate is Smooth and Quiet

- It Holds Big Stuff, Part XXVII

- New Horizon

- Mucho Trips to Target

- I Decided to Buy Something Else

- Tires

- Seat Comfort Gone Wrong

- Even Syncier

- You Don't Need a Family to Dig It

- Wii Love the Sunroof Gap

- Sirius Link to a Drive-In Movie

- Mission Accomplished

- 30,000 Miles & Counting

- Frisco to Oregon

- Our Favorite Caption

- Driving Position Update

- You Write the Caption

- Gold Beach to Bend

- A Day in Bend

- Bend to Reno, Nevada

- Reno to Mammoth Lakes

- A Delicious Milestone?

- Mammoth Lakes to Home

- Wrap-Up & Clean-Up

- Sunroof Gap Walkaround

- The White Knight to our Dark Knight

- Massive Sunvisor

- Automatic Seat Not So Automatic

- A Rare Bird in So Cal

- Bachelor Party Approved

- Maintenance Required

- Taking One For the Team

- My Biggest Gripe is Solved for 2010

- An Upgrade to First Class

- In Sync with text messaging

- Cool

- 2009 Ford Flex Versus EcoBoost V6

- The Missing Piece

- Haulin'

- Our Favorite Caption

- You Write the Caption

- Rear Tire Wear

- 366 Days Later

- Boxier than My Speakers

- Still Solid

- Likes and Dislikes

- Lights, Camera, Sunburn?

- I Don't Want to See It Go

- Updating Sync to Handle New Phones

- First Rain

- Thanks for the Memory...Or Not

- Holy Crap! 40,000?!?

- Oh No, Not Another Oregon Road Trip!

- Arrival in Oregon

- Going Nowhere

- 13 Hours in the Saddle

- Our Favorite Caption

- You Write the Caption

- Barely Showing Its Age

- Rock Chip

- Surprise Rear-Seat Luxury

- Rear Wiper

- Our Favorite Caption

- You Write the Caption

- The Happiest Place on Earth

- Rain Patterns

- Surprise Utility

- Voyage to Vegas Notes

- IL Carpool Vehicle of Choice

- A Bad Romance

- An Olympic Journey Day 1

- An Olympic Journey Day 2

- It Costs How Much?

- An Olympic Journey Day 3

- An Olympic Journey Day 7

- An Olympic Journey Days 8 & 9

- Our Favorite Caption

- You Write the Caption

- Ford's Nav vs. iPhone

- Doesn't Smell Like Riswick

- Editors' Favorites Number Four

- Is It Flexible Enough?

- Trip to San Francisco

- Still a Looker

- One Step Closer to 100k

- A Tiring Task Made Easy

- Get the EcoBoost V6 for Towing

- Out of Lock

- 0 Miles To E for 21 Miles

- Front Brakes are Warped

- Slide, Baby, Slide

- Worst Shifter in the Entire History of the World

- The Fridge is a Rip Off

- Seats Are Very Easy To Fold

- Taking Us Out To The Ballgame

- Vanity Run Amok

- Power Cubby

- Land Bizjet

- Lucky Numbers?

- Pad and Rotor Change Interrupted

- DIY Oil Change

- Tour de Cali

- Yep, Still A Great Highway Cruiser

- An Ideal Location For Reusable Bags

- Leather Seats Still Look Good

- The Forgotten Keypad

- Fits Even More Stuff

- We Like It But You Don't

- Uh, Ford?

- Gauges

- Non-Painstaking Parking

- Our Favorite Caption

- You Write the Caption

- West Coast Run — Cargo & Oil

- West Coast Run — S.F. Fun

- West Coast Run — HWY 1

- West Coast Run — Tree Me

- West Coast Run — Wild Thing

- West Coast Run — Glare

- No Ladder Necessary

- Bike Hauler It Ain't

- Broken Windshield

- Turning 60 In a Wagon

- What's That Button For?

- The Problem With Rear Seat Captain's Chairs

- The Wife Test

- Family Truckster Redux

- In Raider Nation

- Packin'

- Back In SoCal

- A Few Images From the Road

- Wyoming Road trip Fuel Data

- DIY Brake Pad and Rotor Change

- The Joy Of The Road

- Our Favorite Caption

- You Write the Caption

- In Odd Company

- Name That Car

- What is the Plural of Moose?

- That Grinding Feeling

- DIY Rear Brake Pad and Rotor Change

- Power Back Door is Not a Guillotine

- Making My Life Easier

- Missing Piece

- Tall Cold One

- Two-Thirds of the Way to 100K

- ABS Pulsing

- You Can Take the Girl Outta Michigan...

- Like an Old Couch

- Different Perspective

- Paint Chips

- Mount Whitney Road Trip

- Mount Whitney Road Trip - Day Two

- Mt. Whitney Road Trip - Day Three - Hot Brakes

- Mt. Whitney Road Trip - Summary

- Touch Me

- Let's Go to a Crash

- Those Cold Cali Mornings

- See Ya Later, Tailgator

- 2009 Ford Flex Sparks Spark Woody

- Dealer Service Shuttle

- Hot Bath

- Clean Screens Make Me Happy

- Audio Review

- Happy 70th, Flex.

- Flex Across America Challenge

- Tour of a Dirty Flex Part II

- Tour of a Dirty Flex

- Hey, There's a Clock Down There

- Best Soccer Dad Battle Wagon - Flex or Odyssey?

- Time For A Change

- Precious Cargo Hauler

- Maybe In Khaki

- A Stern Experiment

- Hooray for Hollywood

- DOA

- New Battery and Oil Change

- Still Stylish or Just Out of Fashion?

- Which Would You Choose?

- What I Hauled This Weekend

- Easy Fuel Spill

- Priced for Sale

- Our Favorite Caption (for the last time)

- You Write the Caption (for the last time)

- One Important Detail

- Farewell Road Trip

- A Quick Sale

- From the Archives

- Wrap-Up

Introduction

The 2009 Ford Flex Limited is not some kind of traditional Ford minivan. We remember the last Ford minivan, and it wasn't pretty.

There was no fanfare, no 21-gun salute and no teary-eyed widow at the gates of Ford's plant in Oakville, Ontario, as the final Ford Freestar rolled off the line in November 2006. Minivans, the embodiment of the 2.5-children, dog-in-tow American dream, were lost in the wake of the SUV boom. And while Chrysler toiled away at a new generation of minivans — and Honda and Toyota were still selling 'em at a goodly rate — Ford quietly said good-bye as its sliding-door seven-seater slipped quietly into that good night.

The Ford Edge replaced the Windstar and Freestar, both in market segment and on the assembly line. By most accounts, the Edge is a success: stylish, competitively fuel-efficient, and one of the top-selling crossover utility vehicles on the market. But a crossover can't be a people-packing minivan. It lacks the cargo space, the passenger accessibility and the road-hugging size that made the minivan the most ubiquitous vehicle of the 1980s.

The Ford Flex is a kind of crossover that secretly wants to be a minivan. While Ford didn't adopt sliding doors in order to avoid the curse of minivan identity, the 2009 Ford Flex Limited makes amends to the minivan faithful, although it does so with the trendy design language of the 2005 Ford Fairlane concept. We accept Ford's apology and look forward to a 12-month, 20,000-mile long-term test of the coolest family hauler around.

What We Bought

The 2009 Ford Flex starts off well enough at $28,995 out the door. Though this would've gotten us the same 262-horsepower 3.5-liter V6 and six-speed transmission that sits in our Limited, we would have seriously missed out. The Limited comes with a power tailgate, multiadjustable memory seats, power-adjustable pedals, HID headlamps, interior ambient lighting that can be selected from an array of colors, and when coupled with the $2,375 navigation system, even an analog clock. (Because the 2008 Buick Enclave that's in our long-term test fleet has an analog clock, we decided that we shouldn't play favorites.)

The $2,400 for a navigation system (with back-up camera) was a big hit to our wallet, but the options sheet still beckoned us onward. The $55 for rubber floor mats? Have you priced a carpet shampooer rental lately? Done deal. The 40/40-split auto-fold rear seats ran $870, an option that offers access space for passengers to enter the third row. Turns out, we're pretty comfortable just making the third rowers (who we can't like nearly as much as the first- or second-row passengers) climb back there as best they can.

So when we heard that Ford can, for a meager $760, fill that void with a real compressor-driven refrigerator (as opposed to other "refrigerators" in vehicles that simply reroute air-conditioning to an insulated box), we were wholeheartedly onboard. As long as our second-row patrons were living the lavish life with reclining heated seats, a 110-volt power outlet and a $100 floor console, we decided to really let them enjoy themselves with the $1,020 DVD entertainment system. And, because the one Flex Limited in stock that had the Johnny Cash-style black-on-black color scheme we wanted also came with a panorama sunroof, we had to pay the extra $1,495.

The sticker says $42,080 but thanks to a sluggish economy, high gas prices and a highly competitive market (not to mention a silver tongue when it comes to bargaining), we wrote a check for $37,658 and left with a shiny new 2009 Ford Flex Limited.

Why We Bought It

"When you're behind the wheel, the Flex feels low to the ground and comfortably sure-footed, kind of like a really big Ford Taurus, only good," Executive Editor Michael Jordan wrote in our full test of an all-wheel-drive Flex. The same rings true for every Flex throughout the model line, emphasis on the "good." Interior materials are top-notch. The infotainment system isn't just class-leading, it's industry-leading, combining a high-resolution screen that displays not only directions but traffic and weather. This system is also connected to Sync, the Microsoft-designed software that integrates all of the entertainment systems in the vehicle — including Bluetooth phone and iPod — via voice commands. And then there's the ride; the Flex rides like a big, comfortable American car. The kind we grew up in, but good. We like that.

Ford estimates that some 100,000 other people each year will feel the same way. For the next 12 months, we're (collectively) one of those 100,000 people. We put our money where our mouth is because, at first blush, the 2009 Ford Flex is the first crossover that does what it's supposed to do: drive like a car, haul kids like an SUV and look like it's going out on the town.

Current Odometer: 1,687

Best Fuel Economy: 18.1 mpg

Worst Fuel Economy: 16.1 mpg

Average Fuel Economy (over the life of the vehicle): 17.2 mpg

Edmunds purchased this vehicle for the purposes of evaluation.

Living with our 2009 Ford Flex long-term car for over a week confirmed what I'd already figured — when it comes to carting people and things around, this crossover gets the job done with both style and grace. The Flex inspired multiple double-takes and a few questions from onlookers during the week, and its plush interior, car-like handling and multiple gadgets (my kids loved the idea of a rear-seat 'fridge) made it a pleasant family tote bag for the most part.

Only two issues arose during my drive time. The first related to the car's flashy, 19-inch chrome wheels. These certainly enhance the Flex's looks, but on a vehicle with this much wheelbase (117.9 inches) keeping them away from curbs can be difficult. I found this out while going through the local McDonald's drive-thru, a path I've travelled several dozen times without incident. This time, however, I scraped the driver's-side rear wheel as I made the turn between order and pick-up.

I couldn't believe it, and looking at the odometer I thought 'Well, at 1,850 miles I guess the wheels are broken in.' When I got home I went to inspect the damage and noticed that while the rear wheel had a couple scrapes (pictured above), the front wheel (which never got near a curb during my use of the Flex) had much larger and deeper scrapes (pictured below).

So, apparently I didn't break the car's wheels in after all. But this confirms what I felt after scraping the rear wheel — this car can be tricky to steer though tight places. If anything, the car-like driving quality masks how truly big the Flex is. Normally that's a good thing, but it can also lull you into a false sense of manueverability.

The other problem I encountered came during a gas fill up. I like the idea of Ford's capless fuel system, and it's always worked fine on my Ford GT. But this day, as the fuel pump hit its automatic shut-off point, I heard a dripping sound and looked down to see gas spilling onto the pavement — from behind the Flex's rear quarter panel.

I'm not sure if the pump's shut-off sensor allowed for too much fuel to build up under the capless fuel cap, of if there's a leak at the top of the nozzel. Either way, it was a bit disturbing because the fuel came out from a location we don't have access to with this capless system. We'll keep an eye on the issue and see if it happens again.

Ford just might have pulled it off. For years, I've told anyone who'd listen that the first company that makes a cool minivan will create the next must-have family hauler trend and score big. The 2009 Ford Flex just might be the template for that cool minivan — or whatever you want to call it.

'It looks like a big Scion,' said the caretaker at our secret test location. And I've gotten more than one double-take and enthusiastic thumbs-up from other drivers while commuting in our Flex, some on crotch rockets and one from a genuine first-generation Scion xB pilot.

From some angles the Flex manages to look like a chopped-top surf wagon — especially with the optional white roof. And the embossed side strakes somehow say 'woodie', but minus the dry rot and termites. It would look at home with a pair of surfboards on top. But what to call it?

The Flex is no SUV, that's for sure, and the word "crossover" doesn't seem to apply either because those so labelled have typically tried to look like kinder, gentler SUVs. This gives off no such vibe. But it feels too big and substantial to be a wagon. Despite appearing much lower, the Flex stands less than two inches (the short side of a business card) shorter than my wife's '03 Odyssey minivan, but the rear doors aren't sliders.

But the local car wash down the street doesn't care about marketing doublespeak and car classification conundrums; all they know is that I needed to be charged a buck extra for it being an "SUV / minivan" when I had it hosed-off this morning.

I don't care what it's called. I like it.

One thing needs attention before I could own one (and I just might — Tracy thinks it's cool, as well). The seating position doesn't work for 6'2" tall me. The seats themselves are great, but when they're slid back far enough for my legs I can't reach the steering wheel properly. I have to hunch forward a full two inches further than optimal to drive it — the same feeling I got in our long-term Honda Fit. Like the old Fit, this one really needs a telescopic wheel. Oh sure, our Flex has adjustable pedals, but all of the above happens with the pedals as far in as they'll go. Adjustable pedals are a weak substitute for a proper telescopic wheel.

Still, the Flex is cool. If gas prices don't scare folks away from anything bigger than a Focus or Civic, Ford just might have a hit on their hands.

I like big cars and I cannot lie, but there's something about the Flex I can't deny. It's big, not round and frankly just too big for me.

Apparently, the Flex has got it goin' on, till the break of dawn because everywhere I went people were taken with this big wagon. I can see why - it has minivan usefulness without looking like - well, like a minivan. Several neighbors used the phrase 'surf wagon.' Although the Flex feels wide and long on the road, the handling is OK. It never feels sluggish and doesn't have excessive body roll. Nice Job, Ford.

There's nothing quite as American as the road trip. Nothing. Not apple pie. Not baseball. Hell, compared to the road trip even mom looks like a flag-burning communist. And in terms of road trips, this is a good one.

South Bay to Back Bay — 3,024 miles — in the 2009 Ford Flex for my college roommate's wedding. The Flex's excellent nav system, iPod integration, comfy (heated) seats, refrigerator, TV and smooth ride made it my first choice.

I grew up in the age of cheap flights and terrible cars. Planes are faster, easier and probably cheaper — they're also statistically safer. But there's no adventure. No commitment. Even on a long flight the biggest challenge is paying for the on-board snacks. Committing to 6,000 miles of asphalt requires one to abandon all rational thought of the task at hand and just go. It's an adventure. And hopefully it's an adventure that hasn't died in the wake of gas prices and the global warming scare.

Follow along as I blog what will probably turn out to be the worst idea I've ever had. I'll also be Twittering the trip for those times when WiFi isn't available — or I'm just too tired to bother with more than 140 characters.

Wish me luck.

The first leg of this trip was going to be a drag. I knew that much from the start. Southern California up through Vegas, the north western tip of Arizona and then into Utah — it all looks pretty much the same until you get to Arizona, by then though the drive has started to take its toll. But the Flex is, so far, a willing partner in this adventure and I was feeling pretty fresh. When I hit Salina, Utah — only 590 miles from my departure point — the sun had set and route 70 through Utah is a bendy, four-lane highway with a surprisingly high 75-mph speed limit. The highway is also, as the signs indicate, chock full of deer, elk and eagles. I was willing, but the Flex's headlights were not. We paid extra for these HIDs but they simply are not up to the task of illuminating an unlit desert road at 75mph. Maybe it was a good thing, had I been able to 'make time' through Spotted Wolf Canyon, I would have missed some of the best sights I've seen to date.

After being thankfully thrown from my original plan due to the lame headlights on the Flex (even the high beams weren't sufficient in that scenario), I was able to, as posted before, see Utah for all I never really knew it was. I wanted to hit Grand Junction by day one. I've been to Colorado before (for off-road driver training) and was won over by the views and the general 'vibe' of the state. I don't have any data to back this up, but I'm pretty sure there are more bike trails in Colorado than the entire rest of the world combined. (Unfortunately I don't have my bike with me on this leg of the trip...on the way back I will.) Losing my night running hours meant stops had to be ditched. Denver was out. Grand Junction was punctuated. Vail, however, was still very much in.

The Flex, after almost 1,000 miles, is doing well. But, somewhere around 10,000 feet, before the Eisenhower-Johnson Memorial Tunnel (West of Denver) the Flex's second weakness showed. The transmission — which it shares with the Buick Enclave amongst others — just doesn't know what to do with inclines. With no manual option and a lousy L mode, the engine is constantly torn between fuel economy and maintaining momentum. Down. Up. Down. Up. Down. Down. Down. Up. It's not fun. If I were in the Enclave I could just push the button a couple of times, leave the thing in 4 and get on with my trip at a steady RPM. It's a great gearbox in GM vehicles, why isn't it great here at 11,000 feet where I need it?

<

Unfortunately the traffic piled up almost directly outside of the tunnel and continued for about two hours. When the traffic was finished Colorado stopped being fun. The eastern edge into Nebraska is boring. Probably trying to ween drivers off of the grandeur of the Rockies and prepare them for the harsh, bleak reality that awaits them in Nebraska.

When we last left our road trip diary the Ford Flex was whisking us through eastern Colorado and on into Nebraska. Thrilling, I know. With 75 mph limits, straight roads and just enough traffic to avoid being the only car on the road, this was the Flex's time to shine. And shine it did. I turned on my Valentine One, set the cruise control and drove for hours in perfect comfort. Once acclimated to the system, Sync works exceptionally well with an iPod. Sirius' weather link kept me apprised of the looming thunderstorms (which eventually halted my run), and the flat-looking seats kept my butt supported and warm with no complaints. I also managed to, at those speeds, beat the EPA estimated 24mpg with a 25.7mpg tank.

That night I tried, for the first time, sleeping in the Flex. I was hoping the back, seats folded flat, would make an acceptable bed. They don't. It's like sleeping on the floor of a dog's kennel. The front seats don't recline enough for sleeping either. The second row bench is interrupted by the refrigerator so that's out, too. I had an easier time sleeping in our old Lancer than I did in the Flex. That was the last night we tried that. For a detailed account of the rest of that day — including Iowa — please see my illustration below. <

But hey, I got to go to the world's largest truck stop! The truck stop dentist wasn't in my plan.

That'll show all those other truck stops without embroidery shops!

Nothing worse than a road trip with a dirty dog.

Made it.

The drive east from Ohio into New York and then into Massachusetts is like driving through a calendar. The leaves are starting to turn, the rolling fields are dotted with peeling white or red paint, and air freshens up. It also has a little something that the west coast doesn't have, weather. More specifically, rain. It was another chance to try out the live radar-map some more. The big green thing on the screen tells me where the rain is. So do the rain drops on my window.

With its black-on-black color scheme (no mini-cooper/FJ white roof for us!) some have complained that our 2009 Ford Flex Limited looks like a hearse. So I took it to one of New England's newest cemetery — established in the 1720s — for a better field of reference. Indeed, it does look a bit like a hearse. But the kind of cool hearse that you'd see on open drag nights with a tubbed rear, big block and skull shifter. Except that this has a V6, FWD and a six-speed auto.

While it may not be able to do a huge burnout, and it doesn't have those cool curtains hearses do, it is still the best road trip car available today.

Sure, at 42 grand it's not the cheapest. And averaging 25/26 mpg it's not the most efficient. But when you add up everything — fridge, nav, DVD player, roominess, comfort — there simply isn't a better car for driving 8,000 miles in a very short period of time in this price range.

You're driving cross-country and back with a girlfriend in tow, what would you take? (I won't accept any answer of R8, GT-R or any Ferrari — you need to make it there and back without having anything replaced, that includes your ear drums, spine and eyeballs that have been shaken loose from your skull.)

This is the interior of the refrigerator inside the 2009 Ford Flex. Pictured is a peanut butter and jelly sandwich. There was also a fluffernutter, but it didn't last long enough to be in the photo. It's a neat idea but the execution here is a little lame. First, they put the rear armrest hinge on the front. Probably to dissuade the driver from attempting to reach in while driving. Sorry, Ford, not gonna work. Humans are where we are today by adapting and bending the will of our opponents, animate or not. It's possible to get inside if one's willing to drive with their foot (cruise control is a necessity here) and contort a little. It's easier still to make your passenger do it. Its second shortcoming is the size. That's not trick photography, folks it really is that small. The third thing wrong with the fridge is the freeze setting. 12-hours and there's only some frost on the side of the water. It keeps things — and even gets things — very cold, but if you're going to give me a button that says freeze, the damn thing better freeze. Solid. Maybe I should have gone 24-hours straight.

The fourth thing that warrants complaints about the availability of a fridge is the lack of a microwave. Don't laugh. It's got a TV and a DVD player and a refrigerator already. Why not? 10 years ago I would have punched the current me for suggesting a car have any of those things. Now I'm jealous of future-Mike for having an in-car microwave.

Take, for instance a road trip across the country. You drive through a town that actually has food that looks safe and edible, but you're just not hungry...or maybe it was so good you want another order to go. Why not? It won't spoil thanks to the modern marvel of refrigeration. But then the problem arises that cold BBQ sucks. Sure, I could've wrapped it in foil and chucked it under the hood for a few hours but that's not the point.

Speaking of Road Trips across the country, today's installment covers the first few days of the return trip. Boston, NYC, Columbus, St. Louis and Tulsa!

The return trip was intended from the beginning to simply be a return. I was going to go the southern route for a change of perspective, but it was going to be a straight shot. Unless, of course, I ran into some crazy road-side nonsense that I simply couldn't resist. Day one was great. I love NYC and got to spend a few hours there before the clock told me I had to leave. Driving west through PA was marked by cops. Lots of them. Everywhere. On the 76 the only thing I saw more frequently than highway patrol was deer carcasses. Seriously, give out some hunting licenses or something, there were dozens. Day one ended in Columbus with no drama.

Day two was Columbus Ohio to Tulsa, OK. Just over 800 miles and save for a short visit to St. Louis, not much to report. Tulsa did have the cheapest recorded gas of the trip, $2.75 / gal. So that was neat.

Day three I hit the wall. Somewhere around Groom Texas I just couldn't do it anymore. I was done. The pressure and dehydration of the last week finally caught up with me and I had to stop. It was a huge disappointment for me, but preventing a horrible crash seemed prudent at the time.

Driving one way was easy. Having to return was proving a bit more problematic.

It was a long (very long) journey, but I've been back for a few days now. Conclusions — including a by-the-numbers account — of the trip are after the jump.

Miles driven: 6,780.2

States visited: 21 (California, Arizona, Nevada, Utah, Colorado, Nebraska, Iowa, Illinois, Indiana, Ohio, Pennsylvania, New York, Massachusetts, New Hampshire, Rhode Island, Connecticut, New Jersey, Missouri, Oklahoma, Texas, New Mexico.)

Days on road: 10

Gallons of fuel used: 304.8

Best Fuel economy: 24.8 mpg through Nebraska with a 75 mph average — maybe slightly higher.

Worst: 17.5 LA traffic + Vegas traffic

Overall Average MPG: 22.2

Cheapest gas: 2.75 in Tulsa.

Longest run on a single tank: 422.3 miles. NY + Western MA

Shortest run: 165.4. Somewhere in Utah a sign said no gas for almost 200 miles. I decided not to risk it.

Speeding tickets: 0 (thanks, Valentine One!)

Breakdowns: 0. Though on the return trip through Arizona the oil change warning illuminated.

Gallons of water (for drinking): 5

Gallons of bug dissolving washer fluid: 1

BBQ Stops: 4

Miles driven on dirt roads instead of highways thanks to nav system: 3

Other Flexes seen on road: 1

Corvette ZR-1s seen on road: 1

Not to get too far into the political sphere here (though I guess I do have a degree in that which I'm sure my parents are thrilled they paid for), but as someone who has lived only in the Northeast and in Southern California, a trip across the nation at ground level is an eye opener — especially during these tough economic times. At ground level it's easy to see history. To see which industry — shipping, textile, farming, manufacturing — built up certain areas and then devastated them when the jobs left. Seeing the towns that have bounced back, the ones that gave up, and the ones that are have just started to grow. Or more frequently now, started to fall. Watching the signs change from Obama / Biden to McCain / Palin and then to Jesus and eventually back to Obama.

Putting a frame of reference on President Bush's comment that our nation is addicted to oil is easy to do here in SoCal with the constant traffic, but it's more than that; an addiction to cheap goods (trucked from the heartland and from port cities) has made entire corridors of the country little more than a string of big-rig fueling stations. And while we're on the subject of addiction, I'm afraid I came across another addiction of ours ( I'm two-for-two in this whole national addiction thing): beef. From sea-to-shining-sea, if corn, wheat or soybeans won't grow, then dagnabit, cattle will. I'm not sure this is great for our collective waistlines or cholesterol count, but it does make BBQ easier to find (and more delicious).

It's a testament to the architects of our society that we can make it all work. The disparity between L.A. and, say, Gallup New Mexico couldn't be greater if there was a sea and a language barrier separating them. But it does and I won't pretend that passing through with short visits has given me any greater insight as to how. In fact, it's made me more confused. All I know is that my text message to Schmidt read "I've never been so happy to see smog" when I passed over the hill and back to LA.

When I first moved to California (for this job) I couldn't understand the allure, why anyone would suffer the traffic, the smog, and the sprawl. But after spending nearly two weeks away from it, I can't imagine why anyone wouldn't pack up and head west.

But I'll get off my soapbox now. Thanks for listening. It was a great trip. If you ever get the chance I recommend it highly. In fact, don't wait for the chance to arise, seek it out. Take a vacation. Quit your job. Just get out on the road and go. But do yourself the favor and figure out a way to do it one way.

Just sayin'.

One notable attribute about our long-term 2009 Ford Flex: road noise is impressively quelled. Even on concrete, only a minimal amount of tire noise makes it into the cabin. (Our car is shod with Hancook Optimo H725 tires.) There's more wind noise than road noise, but even so the Flex remains library quiet during 75-mph highway drives. Too bad Flex owners with squabbling children in back probably won't notice.

Mike actually mentioned this in Part Two of his road trip cross-country odyssey, but it's worth focusing on specifically here. Like on many other Ford products, the Flex's automatic transmission gear selector has just two forward gates: Drive and Low. There's no manual mode.

If you leave it in Drive and are driving on hilly terrain with steep inclines, the transmission hunts between gears in response to your changing throttle inputs. There is a button on the left side of the shifter ('Grade Assist') that drops the transmission out of overdrive. It helps, but it seems to be designed more for getting additional engine braking on declines rather than ideal gearing for inclines. And dropping down to Low seems like overkill.

But wait, there's more...

Meanwhile, you'll notice in the above picture that Ford neglected to include an in-dash gear indicator for the transmission. So anytime you need to see what gear you're in, you'll have to look down to the shifter. I think this is the case for our long-term Edge, too.

Ford got so much right on its new Flex that you'd think these current Ford foibles would have been binned. Guess not.

When not in use, the 2009 Ford Flex's 50/50-split third-row seat folds flat and stores in a fairly deep rear well. When the rear seats are raised, the well is exposed. It's perfect for securing grocery bags, especially if you're using the reusable kind.

A low-production-value video of me raising the third-row seat and operating the power liftgate follows after the jump. Why bother watching Marina's HotForWords on YouTube when you can watch this instead?

The power liftgate is one of the quicker opening units I've encountered recently. Plus, for the opening process, you don't have to wait for any beeping delay; press the button and it goes. Closing the liftgate does take longer, though.

Somehow a 59-inch-long sleeper sofa needs to fit into the back of our long-term Ford Flex.

Voila!

The Flex's 83 cubic feet of cargo space easily swallows the small sofa, its 'hidden' storage box, and the packaged mattress and slipcover.

After four months in service, our 2009 Ford Flex has earned the following fuel economy numbers:

Worst tank: 14.9 mpg

Best tank: 24.8 mpg

Average: 20.1 mpg

Not exactly the 24 mpg that Ford is touting, but not bad, either.

I bought a Christmas tree this weekend. And put it inside the Flex. Because I'm an idiot. Christmas trees have needles. Lots of them. And they come off inside a car. No problem, I figured. 'Tomorrow is Monday and I'll be getting this rig cleaned up before I take it to the office anyway.' This is IL policy, lest you suffer the wrath of Oldham.

The plan comes undone after the jump.

Here's where the long string of logic and justification begins. It was pouring in the OC this morning. Pouring, I say. The kind of rain we don't get in California unless, of course, I need to get a car washed and vacuumed.

'So vacuum it yourself,' you say. Ah, yes, and I would have had there not been a river coming out of the sky. Shop vacs don't work so well under water. Vacuuming water is one thing. Vacuuming under water is quite another I assure you. So I grabbed the handheld vacuum my mother in law bought on QVC (don't ask) and headed for the Flex. I had already spotted the AC outlet on the back of the center console facing the second row — right where I needed to suck the most.

But there was no sucking to be had — at least not courtesy of the Flex. 'Must be the cheap vacuum,' I thought. Nope. Sucks fine when plugged into an outlet in the house.

The Flex's outlet cover reads '110 volts, 150 watts.' Now I'm no expert on electrons, but I'd wager that's simply not enough to power my crappy QVC hand vacuum.

My brother drives a 2002 Ford Explorer and now he's shopping for a new mid-sized SUV. He called me for some advice and I asked he what he was considering. He said, 'We were going to look at that new boxy thing but we're done with Ford.'

I said, 'Hold on a second.'

I bought the 2009 Ford Flex Limited for our long term fleet about two months ago but I hadn't driven it until just recently. On the freeway I noticed it had a very pleasant ride, like a big, heavy luxury car, and it was extremely well insulated. I liked the wide leather seats and loved the feel of the wood and leather steering wheel.

The surprise came when I reached my exit and swung into the spiraling off ramp.

Suddenly, this heavyweight showed it could be level, stable and composed through a tight corner. The only thing that kept it from being downright fun was the light steering.

It's a surprise how big this vehicle is inside. The backseat legroom is amazing! For a big vehicle it gets about 18 mpg in a mix of city and highway conditions which is nothing to write home about.

But could I really recommend this vehicle? Would I buy it? The only thing that puts me off is that, after 12,264 miles I feel a hard upshift from the transmission. That, coupled with the fact that my brother is car shopping because his Explorer's transmission is has a degenerative illness, kept me from being more enthusiastic about this new Ford.

Still, I like the edgy styling, and love the way it drives. So I took the ultimate definitive stance: 'It's worth a test drive.'

I cannot drive this car.

It pains me to say this, because in most ways the Flex is a home run. Its interior materials are what Lincoln's should be. Real adults can lounge comfortably in the third row. The second-row seats are veritable thrones. It performs well. It looks cool. Et cetera.

But I cannot drive this car.

Why? Primarily because of the absolutely demonic angle of the front headrests. In the Flex, 'headrest' is an oxymoron. 'Headpunch' is more like it — these things force your head forward at a ridiculously stern angle, and no, they're not adjustable. It's not just the Flex, either; a number of current Ford products share this flaw. Did anyone actually try this headrest design out before it went into production?

There's also the matter of the steering wheel, which doesn't telescope. Even with the adjustable pedals all the way forward, I can't get my lanky 6'1' frame close enough. My elbows are locked during normal driving, and I have to lean forward in my seat to crank the wheel when turning through an intersection. Hey Ford! Great car! Telescoping steering wheel please!

I like the Flex. I'd like it a lot more if I could drive it.

I see a lot of politicians on TV lately. They say stuff like 'American cars aren't competitive.' I don't know, I've been driving this Flex for a few days now and I can't really see anything that's so bad about it. I'd rather have this than a minivan or even a truck based SUV. The interior is well finished, the car is attractive plus the new nav and audio system is easily class leading.

I'd rather have a Flex than an R-Class, Pacifica, Tahoe, Sienna, Murano and even a Range Rover. Not sure I'd get black though - color aside, this is really a very good family wagon. I could probably name 6 or 7 other American cars that are good enough to put in my garage - the Flex is just one of them.

To almost no one's surprise, I've got the keys to the 2009 Ford Flex in my pocket for our annual holiday trip north to Oregon.

We're all looking forward to it. It has plenty of room for us to stretch out, plenty of room for our stuff and it's loaded with plenty of toys to keep the miles from wearing us out. We'll put the navigation system, satellite radio, Sync iPod connection, Bluetooth connection, rear DVD screen, and built-in cooler to very good use.

We don't actually leave until the day after Christmas, so I have a couple of days to watch the weather and plan my route. Snow is going to be unavoidable this year because we're adding a side trip to Bend to see my sister-in-law. We have to cross the Cascades to get there from the coast.

California and Oregon are militant about the need to carry tire chains and use them. They set up checkpoints. They're dead serious about it. And many times they don't care if you have AWD. This might not be a problem if you're a local and you have snow tires. But if you're driving up from sunny SoCal, you need chains. And the 10-day weather forecast shows that pesky little snowflake icon up north the whole time.

In fact, as I write this, a colleague in our video production department is already in Oregon and he just called not 5 minutes ago from the roadside while installing chains on the Ford Edge. 'Front or rear?' he asked with chattering teeth. I'm not making this up.

And this is where the Flex has a potential problem: The Flex's owner's manual says you can't put chains on a Flex, even so-called S-type cable chains. Chains won't fit, they say, over the standard 18-inch tires as well as the 19 and 20-inch optional ones. (Our front-wheel drive Limited has the 19's.) I've never heard of such a thing on a volume family product. Who signed off on this?

There is one Flex model that can accept chains: the 2WD SE base model can be ordered with an optional 17-inch tire 'downgrade.' They're 1-inch shorter, you see. They provide one-half inch more radial clearance in the fender wheels. The AWD's final drive ratio is borrowed to keep the gearing straight.

But besides a paltry options list, there is a catch: Ford says they only sell this option in 'snow states.' What 'snow state' denizen would go for 2WD and chains? Sounds like a fleet special, to me. And I'm sure places like California and Arizona aren't considered 'snow states,' but both have high mountains and real ski resorts. Folks who live outside snow areas and visit occasionally are the ones who need chains, not the locals who live in it. But I digress.

After a bit of frantic research (the keys to the Grand Caravan were long gone so I had to make this work), I learned a few things:

SAE (Society of Automotive Engineers) standards require 15 mm of clearance (about 5/8 inch) for S-type chains, roughly speaking.

The optional 17-inch tires have the same width as my 19's, but by being shorter they gain 12.7 mm of radial clearance. That's the difference I have to make up.

I found a brand of cable chain that exceeds SAE S-type requirements. They only need 6.3 mm (1/4 inch) of clearance — a savings of 8.7 mm.

Using these slim-fit cable chains with my 19-inch tires reduces the descrepancy to only 4 mm — just over 1/8 inch. I'm sure Ford didn't cut it that close, so I think I'm good. But just to be sure I went down to the garage for some measurements.

The clearance between the tire and the strut isn't really close. There's almost a full inch there. No problem. The fender lip looks good too.

The closest point seems to be the distance between the tread and the rear of the fender liner at full lock. Even with these 'big' tires, it looks really close to the required 15 mm. I easily see more than a half-inch — significantly more than the 1/4 inch required by the slim-fit cable chains.

I'm going for it. At worst I'll simply call my sister-in-law in Bend and tell her we can't get through.

And as Paul in the next cubicle said, going through all of this trouble and buying chains means that Murphy's Law will now protect me with sunny skies and clear roads.

I was struck by a sinking feeling on the day before liftoff to Oregon in our 2009 Ford Flex. Just as the odometer turned over the 13,000 mile mark I noticed that the mileage on the dealer-installed oil change label was identical.

Great. I'm about to embark on a 2,000 mile trip and it looks like the Flex needs an oil change. But didn't it just have one? And how am I going to pull this off on Christmas day?

Out comes the owner's manual to look at the maintenance schedules. The first oil change comes at 7,500 miles; the second at 15,000 miles. This 7,500 mile interval carries through the life of this Ford. Severe service intervals are 5,000 miles, but Ford's definition of 'severe' is quite specific and, well, severe. We don't tow, we don't make deliveries or use it as a taxi. Our driving pattern doesn't come close to meeting any of the threshholds.

So the manual is quite clear that 7,500 miles is the proper oil change interval for the way we drive our Flex.

Vehicle Testing Assistant Mike Magrath texts me to say that the last oil change came a couple of hundred miles after the service reminder light came on. He's home for the holidays and away from the receipts, but we figure it at about 7,800 to 8,000 miles. The next change is therefore due at 15,500 miles or so, not 13,000 miles. Indeed the service reminder light has not yet re-illuminated to indicate that oil change #2 is looming.

So the sticker mileage is either an example of a dealer who doesn't read the manual himself or good old upselling. And check out the 'Motorcraft Full Synthetic' label. More upselling. The Flex neither requires synthetic nor did we spring for it on the last change. By its presence, the label implies that pricier synthetic is required here. But it's just an ad. The Flex needs nothing more than regular 5W-20.

Nice try, guys. Better luck next time. I'll have ithe oil changed when I get back, and I'm not going with synthetic, either.

This is one of several reasons why I usually change my own oil.

'What car are you driving up this year?' asked my dad as we called to report our progress from the road.

'It's a 2009 Ford Flex,' I replied.

'A what?'

'A Ford Flex. It's new.'

'Never heard of it. Does it run on ethanol?'

'No, it won't run on E85.'

'Why do they call it Flex, then?'

Good question. I have no answer to that one.

Dad wasn't the only one to make the incorrect flex-fuel assupmtion, either. Two or three other relatives I saw over the last two days made the same deduction. It's such an easy conclusion to draw, apparently, that Ford felt the need to emblazon the Easy Fuel filler neck with 'no E85' icons. I don't remember seeing anything like it on any other car that won't run on E85. But, then again, none of them are called 'Flex,' either.

This misconception seems so pervasive that I have to wonder if the Flex is being dismissed as a vehicle choice by those who either don't have E85 in their area or don't believe in the stuff. That'd be a shame, because this is one nice ride.

As for the Easy Fuel itself, I'm still not used to the lack of a cap. I have to wonder if those who have a two-car stable, one with Easy Fuel and one without, ever get used to it.

All that aside, we burned two tanks totalling 30.06 gallons of regular unleaded today over 682.8 miles of mostly high speed freeway driving, for an average fuel economy of 22.7 mpg. The in-car gauge apparently reads a bit high; it reported the day's average as 23.6 mpg.

Phase One of our holiday odyssey in the 2009 Ford Flex has come to an end. We've arrived at my parents' place near Brookings, Oregon after some 830 miles in the saddle.

But not until after we made our now-customary lunch stop at the Lost Coast Brewing Company in Eureka, California. The above painted wall mural frames one end of the parking lot across the street.

So far, our intrepid crew has nothing but good things to say about the Flex:

The ride was smooth and comfortable, yet body motions were never buoyant or floaty. This is quite a trick on many northern California highways, distorted as they are by frequent land slippage and roadbed settling. Kudos to the suspension tuning crew at Ford.

We sit lower in a Flex than a minivan or big SUV and the lower roofline produces a lower center of gravity. Inside, we feel less roll movement in corners. I'm not sure if this is because the body actually rolls less, if it rolls the same but more gradually, or if our lower seated position (closer to the roll axis) results in less seat displacement for a given amount of roll. It's probably a case of 'All of the Above.'

Bottom line, no one got car sick this time — even with their heads buried in a book, playing with their Nintendos or watching the DVD screen.

And everyone loved the Flex's entertainment system. The kids found it easy to manipulate the system to keep themselves busy with movies in the back, while Tracy and I kept the iPod going up front. I only wish the Sync interface provided better control over audiobooks. They don't show up under genre. You have to select the author, Neil Gaiman in this case, as if he were a band, or something. And trying to listen to a continuous 7-hour track with no chapter markers is a pain. A book should be an album, and chapters should be tracks. But they aren't.

Even so, the touch screen controls for it all, made possible by the navigation screen, kept it all running smoothly.

And then there are the seats. Stormy weather and cold fuel and food stops made the front and rear seat heaters a big hit. Some of you scoffed at the wrinkly look of the seats themselves in my pre-trip post, but the fact that the leather isn't stretched as tight as a drum made them quite pliable. They squish down just enough in the right spots while providing strategically-placed support over long distances. Sure, they aren't wildly bolstered and sculpted like Recaros, but the Flex isn't a GT-R and it isn't made to haul butt. But it does seem to haul butts rather well.

I can't remember where I heard it, or even if it's true, but the Weather Channel is supposed to be the most-watched cable network. It's hard to fathom in southern California, where this trip in the 2009 Ford Flex Limited began. But here on the Oregon coast it's a lot easier to believe.

Dad has his own weather setup, and he has logged temperature, rainfall and windspeed more or less each day since he moved here from So Cal some 19 years ago. This morning's rain gauge reading was 5.4 inches, the second-highest 24-hour total he's recorded.

Despite this, we pointed the Flex toward Gold Beach, 15 miles away. Our mission: fresh Dungeness crab for tonight's annual crab feed. That's right, some adventerous fisherman was out in it last night, bobbing around in his boat and hauling up crab pots to harvest what would become dinner for a lot of locals around here.

On the way to town, we encountered a rotted tree that had blown down across the road. Further on, we came to a place where the Pistol River had overflowed its banks and overtopped the road. We had another route to choose from, so we got our crab anyway.

The Flex has a really handy pair of 3rd row seats that fold into the floor like most late-model minivans when not in use. But when the third row is in use, a deep well with a surprising amount of space is revealed behind the deployed seatbacks. It was here that our cooler full of fresh crab rode securely, with no need for tie-downs to keep it from moving about on the trip home up convoluted Carpenterville Road.

Want to have some fun at the beach in your 2009 Ford Flex this winter?

Load grandma, grandpa and the kids into all three rows. Don't feel bad about those in the back seats, because all three rows enjoy generous legroom. Despite the flat roofline, the third row sits a bit higher than the second, which in turn sits fractionally higher than the first. Everyone can see out.

Take a couple of slices of stale bread down to the jetty and wait for the seagulls to gather. It won't take long; they know the drill. Roll down the windows a little ways and toss a bit of it out onto the ground. In no time you'll have a couple of dozen new friends.

If you have the multi-panel Vista Roof, toss a few chunks on the roof and all three rows will get a close up lesson in avian flight dynamics and pecking order behavior through the overhead glass.

Before long, certain foreign substances will begin to obscure the view. Head directly to the nearest quarter car wash and rinse thoroughly before it sets.

Or so I've heard.

Turns out our 2009 Ford Flex is well suited to those who aren't so flexible. Dad still gets around pretty well, but he appreciates the Flex on two counts:

The seat height is neither too low nor too high. No gymnastics are required on the mount or the dismount.

The door sill is much narrower than it looks when the door is closed, thanks to a very narrow rocker. He can get into position to sit down while keeping his outside foot planted firmly on the ground.

All of the above applies equally to the front and rear seats.

His one complaint? The grab handle is over the top of the door, where it doesn't do him much good for ingress or egress. He'd prefer the A-pillar location to help him hoist himself in or out. Most Ford trucks and SUVs have A-pillar assist handles, but not the Flex.

Overall, however, Dad finds the 2009 Ford Flex easy to get in and out of.

Today we said goodbye to my parents on the coast and headed inland to Bend, Oregon in our 2009 Ford Flex. Our route took us over a 5,400 foot pass where recent snows had brought the snow accumulation up to over 70 inches.

At least 100 miles of our route was in the snow zone, so as the law around here requires, we carried chains, just in case.

Much of the road had been cleared, but just after we stopped to have the Oregon Department of Transportation's 'Trip Check' road camera record our passage, the route entered an area with 5 and 6% slopes that was still coated with packed snow.

Most of the people we saw parked in the snow play areas were locals and they all had fitted studded tires on their 4x4s. Our front-wheel drive Flex Limited made do with its standard Hankook 235/55R19 all-season tires. We had no trouble, and we didn't have to chain-up.

But even though we had plenty of grip for climbing and turning, the ABS triggered easily and stopping distances were a bit long. If I lived in the white stuff full time, I'd upgrade my tires, too. But on a just-passin'-through basis, the stock rubber did just fine.

Today, after spending Day 7 doing nothing but recovering from the previous night's celebrations and watching football, we finally pointed our 2009 Ford Flex southward for the trip home. The weather forecast called for conditions conducive to the formation of ice. It had rained overnight, and then the temperature dropped below freezing.

Indeed the icy black asphalt of our hotel's parking lot was hard to walk across as we loaded-up. But we couldn't dawdle too long waiting for sunshine because we needed to get past Weed, California, some 200 miles south, before the predicted snow arrived there at 2pm.

After a few test laps of the parking lot, the front-wheel drive Flex felt secure enough on its all-season rubber and we lumbered out of town as the in-car temperature gauge dropped to 29 degrees and stayed there. It had snowed overnight along highway 97, and we padded along with a group of other cars at 35 mph in places where the plows hadn't yet scraped or sprayed de-icing fluid. We had no problems with grip, but then I wasn't demanding much as I squeezed the throttle like a hypermiler and used sparing steering inputs.

One of the negative points of the Flex is the small swept area of the rear window wiper. Not sure if this can be helped because of the car's basic proportions, but I found myself wishing for more, especially toward the driver's side.

We kept a steady pace and got completely out of snow country without incident. One overturned Ford Expedition we saw couldn't say the same, but everyone looked OK.

After clearing snow country for good, we stopped for a late lunch. It was then I noticed that we had been getting excellent mileage, so I delayed refueling to see how far I could stretch the tank. At some point the remaining fuel range dipped below 50 miles and the navigation screen automatically zoomed-in and displayed fuel station POI icons, even though I hadn't pre-selected them.

We eventually stopped after 454.5 miles and installed 17.052 gallons of 87 octane. That's 26.7 mpg, nearly 3 mpg higher than the Flex's highway fuel economy rating. The on-board display was more 'optimistic,' as it had been at each and every previous fill-up. It read 27.9 mpg when we finally rolled up to the pump. But I trust my own calculated number more.

Our 2009 Ford Flex is spending tonight in my driveway wearing 9 days worth of road grime. As for us, we're only a little bit cleaner, but we're happy to be sleeping in our own beds.

Earlier on I'd passed along my dad's praise for the narrow door sills and how they ease ingress and egress. An alert reader pointed out that this would keep one's pants leg from getting dirty, too. At first I thought this comment had to do with the geometry of the design and how it made it less likely that one's pants leg would drag across the narrower sill when getting in. But there's more to it than that.

No matter what sort of choas is going on outside, the sill never gets the least bit dirty. Just look at that shine! This is because of the way the bottom of the door wraps around and cups the door sill. And there are seals down there, too.

I just put a load of jeans in the wash, and none of them had schmutz on the pant legs. For this reason, the Flex gets my vote as the #1 job interview car for anyone living and working in ice and snow country.

No doubt this byzantine arrangement is also a big reason why we experienced a rather low amount of road noise on a variety of surfaces.

Yesterday we'd achieved 26.7 mpg coming down out of the mountains, but the overall drop in altitude and the slow pace and delicate throttle inputs forced upon us by the weather made me wonder if this figure was a fluke. After all, the front-wheel drive Flex is EPA certified at 24 mpg on the highway.

On today's last leg, I steadfastly used the cruise control, alternating the set-point between 65 and 70 mph as the speed limit varied likewise. The route from Fresno starts out flat, but then it climbs sharply to over 4,000 feet and dithers up and down a bit before dropping back near sea level in the LA basin. And of course there were a couple of potty stops. All in all, this wasn't the driving profile I'd have chosen to determine maximum fuel economy. But at least it was realistic.

The result? 26.5 mpg. As usual, the on-board computer exaggerated like a novice fisherman and claimed a 27.8 mpg performance.

After I get a good night's sleep, I'll summarize my accumulated Ford Flex impressions on Monday. Or Tuesday. I need a break.

It's over. The 2009 Ford Flex has been washed and gassed for the final time and the keys are in someone else's hands for a change.

All told, our trip lasted 2,275 miles. Over that distance, I added a total of 99.8 gallons of unleaded gasoline.

Average trip fuel economy: 22.8 mpg (Enclave last year = 22.1)

Best tanks: 26.7 and 26.5 mpg (Enclave last year = 25.6)

Longest run: 454.5 miles

Worst tank: 18.2 mpg (multiple runs up the steep switchbacks to my folks' mountaintop lair after feeding seagulls and such)

Number of other Ford Flexes seen on the road: Zero (dealer lots don't count.)

Yes, but what do we think after all of that time?

Of all the long-term cars my family has taken on this trip, this 2009 Ford Flex Limited is far and away our favorite. If not for the fact that it's already paid off and we don't want to take on a new car payment, my wife would gladly ditch our previous-generation 2003 Honda Odyssey for one of these. I can get behind that.

The Flex rides and handles better than any other long-term car we've taken over this route. Ford got the suspension right: It rides comfortably, but doesn't roll excessively or float and bob over waves in the pavement. On the same roads, the Jeep Commander had been an absolute vomit comet. The Enclave was better, but still tended toward queasy in the coastal mountain highways of northern California; too much 'Buick ride' for this terrain.

Our departed Cadillac SRX was perhaps as good as the Flex in this regard, and it steered a bit more precisely. But it's only a player for the summer version of this trip. I wouldn't chose it it for the winter edition on two counts: The cargo area and 5-seat layout is too small for holiday duty and I would have been reluctant to take the rear-wheel drive SRX in the snow.

We made a lot of side trip to places like the 'cat houses' on the Gold Beach jetty (above), so there were many occasions where we had 6 people in the car: 4 adults, 1 pre-teen and 1 kid-sister. The Flex excels in front and middle seat legroom; the latter is almost limo-like. Even the third row is quite roomy, and a nifty flip-fold mechanism makes them easy to get in and out of.

The seats are comfy enough, but, as Josh mentioned earlier, the headrests jut too far forward and are not adjustable for rake. And I desperately needed a telescopic steering wheel to bring the rim at least an inch closer.

Cargo space is less cavernous than an Odyssey, but for us, it was more than enough. And the fold-flat third row reveals a deep storage well when the seats are in use, so there's still a lot of room back there for groceries. But the presence of first and second row consoles make the 2x4-down-the-middle trick impossible. Even though it doesn't totally avoid the issue, I'd pass on the rear console and integrated cooler; we didn't use it much, anyway.

The lines are so straight on this thing that a sliding rear door would seem to be easy to implement gracefully and not ruin the look. Ford should have done it. As it stands, the rear doors are long and they need to be opened wide. 'Let me pull out of this parking space [or garage] before you get in,' was a common refrain on this trip.

Finally, there are the electronics. This was a slam-dunk hit. The kids played DVDs in the back, they used the 110V outlet to keep their Nintendos charged-up, and we kept the iPod running up front playing through the interface built into the nav screen. One complaint: every page needs a 'back' button to retreat one level. Synch made us go back to the main menu and work back from there to where we were. Annoying.

The navigation system works pretty well, but the database it feeds from is still full of errors. Like the Enclave before it, the Flex tried to route us through the same locked gate across private property. For this and other reasons, I'm not ready to fork over tons of cash for a factory system just yet.

The engine isn't particularly strong, but neither is it weak. The biggest problem I faced is the lack of a way to downshift out of drive to a desired lower gear. There are only two choices: D or L. Well, there is a 'Grade Assist' button that tries to do something, but the response was never consistent and it never did what I wanted. Just let me pick the gear, OK? Your computer can't see down the road. I can.

And the Ford Flex looks very cool. I know, I know. Image isn't everything. But for a people hauler, I like looking at it. And I have no doubt that the lower stance is one of the main reasons why this crew arrived at our final destination without stomach upset and largely intact.

For me, the 2009 Ford Flex is a good candidate to replace our current minivan when it finally wears out. Or maybe when it wears out its welcome. At this rate, that might happen sooner rather than later.

I just spent an enjoyable weekend in our long-term 2009 Ford Flex. It's not exactly a perfect vehicle, but it's as close as Ford has gotten to perfect in a very long time. Although I have issue with the Flex's seating position and its shifter, most of the time I find myself thinking, 'Man this is a well done vehicle,' or some such gush. I've even recommended it to several friends.

One thing that jumped out at me this weekend was the Flex's solidity. So far our Flex does not have a single squeak or rattle. There's no loose trim. No bugs in the Sync or navigation systems. In fact, after more that 16,000 miles in just six months you'd swear our Flex is brand new.

Okay, it did have to return to the dealer once for an unscheduled fix; at 1,686 miles its brakelights stayed on, so Santa Monica Ford replaced the brake pedal switch. But that's it. Otherwise solid as a rock. If you ask me, one trip to the dealer in 16,000 miles is a record any vehicle manufacturer would be proud of.

Now I don't know how the Flex is going to hold up over the next six months or six years, but up until this point, it's been one of our most reliable and durable long-term cars ever.

Thanks to edubya for this week's favorite.

Quite a few gave us a good chuckle. These commenters get honorable mention:

Ford Flex found soiled. Fowl play suspected. (eidolways)

Gullible buyers welcome. (eidolways)

Ford introduces a new Gull Wing option for the Flex (wable)

Ford reveals eco-friendly two tone paint facility. (vwthing1)

With this, we can strike anywhere, anytime. We're unstoppable! Drive on puny human! (gooney911)

What was your favorite?

Here is a lovely scenic photo taken by our Director of Vehicle Testing Dan Edmunds.

Our Vehicle Testing Manager Mike Schmidt came up with 'Talk to me, Goose.'

Can you do better?

We'll post our favorite at 4PM (Pacific Time).

We Got Weather

Now that I'm armed with a video camera, I'm going to drive you CRAZY with moving images. You're gonna get video on EVERYTHING.

As Socrates once said, 'An unvlogged life is not worth living.'

Here's a video montage of driving the Ford Flex in the rain on my morning commute.

In the second segment, that big gray thing you see looming in the distance is the Pacific Ocean. You'll get a closer look at it in the third segment. Don't worry the whole thing is only a minute long.

The other day our 2009 Ford Flex took a shot in traffic. Not our fault. The damage seems to be cosmetic and limited to the plastic bumper cover, but we'll let you know how it all plays out. Body shop here we come...probably next week. Heck, maybe it'll just buff out.

With just over 17,000 miles on the odometer, our 2009 Ford Flex Limited is requesting an oil change.

Edmunds' Maintenance Guide estimates we should pay $28.74 in parts (oil and filter) and $63.00 labor for the LOF and tire rotation in our Santa Monica zip code.

We'll see what our local dealer has to say.

Our long-term 2009 Ford Flex Limited pulled light-aircraft duty this past week, shuttling us on an 1,800-mile extended ski weekend to Colorado, and earning a spot on any traveling family's must-consider list. Like a gentlemen's smoking club on wheels, our leather-lined and faux-wood trimmed black Flex Limited is a road-trip tour de force, providing a swift and serene environment capable of hauling the mail or whatever else you wish to carry, while coddling you with impressively integrated electronic conveniences.

We unleashed the Flex on the interstate, where it painlessly delivered us from L.A. to Vail, CO in a single 13-hour/900-mile stint. With the cruise set reasonably close this route's near-constant 75-mph speed limit, the Flex ate up the miles while hauling a ridiculous amount of gear and luggage for a six-day outing on the slopes. With all the rear seats folded flat, cargo space was a non-issue in the Flex, and few circumstances let you pack with such abandon. No need for roof racks as the Flex happily ate our ski box in the cavernous cargo area, with tons of room to spare for luggage ahead or behind it. Did we overpack? Heck yeah. Did it matter? No.

Rolling down the road, the Flex's long wheelbase and soft suspension soaked up road irregularities and showed the cabin to be impressively hushed at speed. Though the early movement in the Flex's suspension is pillowy (great for freeway slab), just beneath lies firmer travel, a setup that helps keep the Flex surprisingly planted and composed in fast sweeping turns, even if body roll is apparent.

The overboosted steering is a boon to interstate miles, and though effort is light, Ford has found a touring sweet spot, as the tiller remains accurate in spite of the boost. This easy but precise tuning helps keep fatigue at bay as you devour 400 miles per tank. The 3.5-liter V6 does not overpower the Flex, but it's quite smooth at cruising speeds, and plenty grunty to keep the Flex out of its own way. While sailing up the continent's spine, we still managed 20.5 mpg.

With light bathing in from the multi-panel Vista Roof, and a southwestern U.S. geography lesson whispering by tall windows, you could not help but feel pride in such a sweet modern version of the classic American station wagon. Ford has updated an icon in duds so cool you couldn't help but feel envy from the minivan set, while providing convenience features you could only dream about in the '70s.

As far as entertainment goes, Ford's latest navigation system with Sync is the benchmark. The large and crystalline screen can be split for simultaneous feedback on navigation, media, and climate control status. The back-up camera is clear and bright, even at night. From Sirius satellite radio to iPod tunes recalled via voice command to a sleep-inducing Jane Austen book on CD, the system is a delight to use, and you can easily catch up on overdue family calls via the voice activated Bluetooth setup. Even with my surname, it never mis-dialed a call to family members.

Once in Vail and what seemed like most of our worldly possessions were hauled out of the Flex, it earned its name by instantly converting to a sweet, three-row shuttle for the trio of couples on hand. If you know to look for the switches, rearmost-seat access is an easy button push away. Even with some exceedingly tall (6'3", 6'5") and annoyingly capable ski pals in the elevated rear seat, there was headroom aplenty (how these clowns managed such lovely brides, I'll never know...).

Coupled to a general sense of refinement, mostly due to the often unheralded substance in Ford's latest interiors, the upcoming twin-turbocharged, all-wheel-drive version of the Flex is destined to become a common sight in ski-towns around the U.S.A. The clunky turn-signal/wiper/high-beam stalk combo could really use retirement, and larger, seat-eating traveling broods will need a roof rack for all the skis and luggage, but the extra power and grip is sure to make that Flex a covetable ride in any tax bracket.

Until that SHO-like version of the Flex arrives, there's not much in the current Flex for real driving enthusiasts. In its element of clicking off straight miles while carrying lots of anything, the Flex's sharp but low-effort steering and cushy ride will offend no one, and the dead-pedal is well placed for your left foot. Far more long-haul friend than canyon carver, every time you look in the rear-view mirror and sense the hatch lingering back in the previous zipcode, you think, 'This thing's pretty slick for a school bus.'

By the time we knocked off our second, straight-shot, 900-mile stint home (only 12:45 heading back - must have had a tailwind) where we averaged 20.7 mpg, I'd become a convert. The Flex Limited is so cool, so comfortable at eating miles, so completely slick in its electronic complement, it makes you want to expand your family and get out and see the U.S.A. If the domestic auto industry lives to thrive again, it will be because of vehicles like the Flex.

Our Long Term 2009 Ford Flex limited just got back from an oil change, tire rotation and brake inspection over at Santa Monica Ford. Preliminary estimates predicted this service to cost about 90 bucks here in Santa Monica. It didn't.

$44.59 and a few hours later the Flex was ready to roll. The service advisor even gave me a form to fill out for a $10 mail-in-rebate on the service. The ownership experience with this car just keeps getting better.

Just like our long-term Subaru Impreza WRX, our 2009 Ford Flex Limited cruised its 20,000th mile this weekend.

Unlike in the WRX (which has been with us about 4 months longer), it only took us about 8 months to run the Flex's odometer to the 20,000 milestone. I don't know if tha'ts a long-term fleet record (and I'm sure you'll tell me, if it is), but it's obvious that we like this boxy crossover. It seems to like us, too, as it's given us little trouble.

To date: three major road trips (Oregon and back, Massachusetts and back, Utah and back), two scheduled oil changes, one visit to the dealer for brakelights staying on, one not-our-fault bumper scrape.

I've spent a good deal of time in the Ford Flex, just not our particular long termer. Last summer, I journeyed up to Big Bear Lake, California, in a Cinnamon-colored short termer and was left thoroughly impressed by its road trip manners. One month later I was in Toronto on vacation and picked up a Light Ice Blue SEL from the same factory in Oakville, Ontario, its Ford family-hauling predecessors were built since 1994. Both the Windstar and Freestar (and Mercury Monterey!) minivans were mediocre-to-horrible for most of their existence, and the fact that these diseased members of an endangered species have been replaced at the Oakville plant and in the Ford lineup by a hopefully game-changing vehicle like the Flex certainly seemed symbolic.

While the Flex doesn't have the same max utility of a minivan, that summer Toronto trip certainly showed it had the type of appeal the Windstar could only dream about.

Photos and more after the jump.

2009 Ford Flex at Ford Canada Headquarters and the adjacent factory that builds the Flex, Edge, Lincoln MKX and MKT.

"Hey James, that's a cool car," said my 13-year-old cousin Cooper after a long look over the Flex. A three-row, six-passenger family mobile shouldn't in theory draw this sort of reaction from a generation devoted to its text messaging, skater boy fashion sense and that quasi-punk band I'd rather not know the name of. But here was such a vehicle appealing to such a kid. At the Toronto airport, a similarly aged boy passed in front of me at a crosswalk and gave me a thumbs up, clearly mouthing "nice car, man." The 22-year-old brother of a friend also thought the Flex was "pretty sweet."

At the same time, my mother loved the Flex. "I wish I would've had one of these when you were a kid." (Although anything would've been better than an '83 Cutlass Cierra). The space, the high-quality interior, the electronic goodies and the styling all had their appeal. A whole host of other adults thought the Flex would make a great family vehicle (mind you, several others thought it was butt-ugly).

The fact that a family hauler can appeal to moms and 14-year-old boys alike is a triumph. How many times does that really happen ... in any realm? If mom and dad can have their three-rows of seats and room for hockey equipment, while skater son can look cool pulling up to the school parking lot, everyone wins. I've been seeing more Flexes on the road recently and once the economy improves, I foresee the Flex being a runaway best-seller. Well done Ford.

The Flex at Ford Canada HQ (left), and at Canada's smallest jail in Coboconk, Ontario

This is what you see when you look over your shoulder in the 2009 Ford Flex. With the third row lowered, you have an amazing amount of glass space (it's not that different with the seat raised). As such, there's really no excuse for errantly backing into things — especially with the rearview camera. The Flex's boxy shape might provide its trademark look, but its subsequent interior space and visibility advantages add to this family vehicle's overall practicality.

Ford's SYNC gets my award for the best bluetooth interface of any vehicle on the market today. It's a simple interface that, with a few button punches, can be easily linked to your phone. And, once bonded, it can easily be reconnected while moving. This wouldn't matter so much if my phone didn't insist on deactivating bluetooth every time it leaves the car. It also allows phone volume adjustment on the audio system volume knob when bluetooth is in use. Excellent.

Taking a page from Mini Cooper and their Mini Motoring Graphics kits, Ford Motor Company announced a similar product for their 2009 Ford Flex.

We've installed a sneak-peek sample on our 2009 Ford Flex long-term test car. The Country Squire Graphics Package, as it's formally called, will be available as a dealer accessory at the beginning of June.

Richard Duschene, senior product planner and strategist for Ford's car division, explained it this way:

'Troubled times call for a back-to-basics approach. We've studied what worked for us in the past, back in the pre-SUV days. What we found was the pinnacle of our popularity among families and the middle class occurred when we were making a lot of station wagons, particularly Country Squire station wagons.'

'We thought for awhile that we could sell the Flex as a crossover, whatever that is. But our customers have been telling us that we're not fooling anyone. The Flex isn't a minivan, and it isn't an SUV. What's left, then, is station wagon. And that's OK.'

'It's so OK, in fact, that we decided to go all-in and put the Flex 'back in the crate', if you will. If customer response is as strong as we think it's going to be, you might see the Country Squire come back as a factory-installed production option.'

'Frankly, that thought gives a lot of folks here at Ford a woodie.'