2009 Nissan 370Z: What's It Like to Live With?

Read the latest updates in our long-term road test of the 2009 Nissan 370Z Touring as our editors live with this car for a year.

What do you want to know about?

- Introduction

- SynchroRev Match Making Things Too Easy?

- A Gauge Cluster Worth Copying

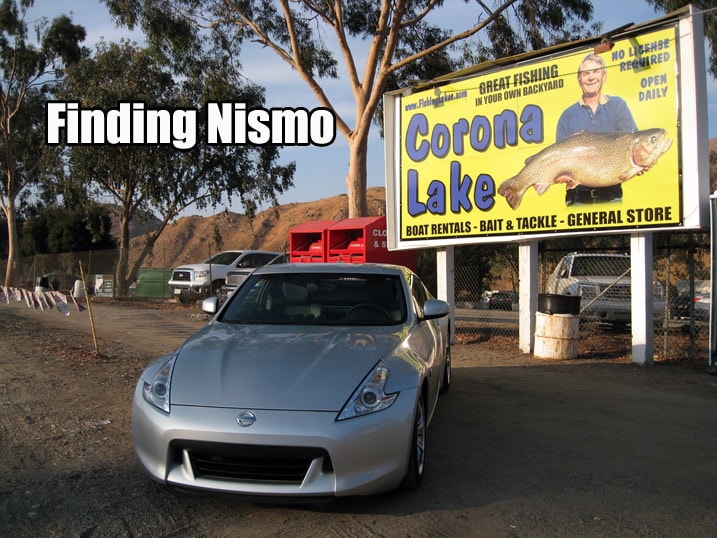

- You Write the Caption

- Our Favorite Caption Two

- Comfort Takes a Back Seat to Driver Involvement

- Small Touches Make It Survivable as a Daily Driver

- 2009 Nissan 370Z vs. 2010 Ford Mustang GT

- Seven Hours in the Driver Seat and I'm Still OK

- Track Tested!

- A Real GT When You Want It to Be

- Guess What? I Can't See You.

- The Decade The Affordable Automotive Music Died

- Facing Off Against the 2010 Mustang

- All-Star Wheel and Tire Sizing

- More Braces Than a Junior Prom

- Not Quite Awesome Enough

- Gear indicated

- No ZZZZs Here

- Taking it on the Chin

- Open Thread Two

- View From the Driver's Seat

- A C.O.W. Twofer

- Oil Cooler Install and First Service

- Suspension Walkaround

- Where Have You Gone, Yutaka Katayama?

- How To Avoid Traffic

- Really Smooth Downshifts

- Keeping Cool on a Hot Day

- Racy

- How Do You Turn on the A/C?

- Numbers, Schmumbers

- Coming Apart at the Sills

- Stink Eye Blind Spot

- Wrong Fuel Gauge

- Seats Done Right

- Is Synchro RevMatch the Way of the Future?

- Brakes and Blips and Revs, Oh My!

- Not for Touring

- So, What Do You Think About It?

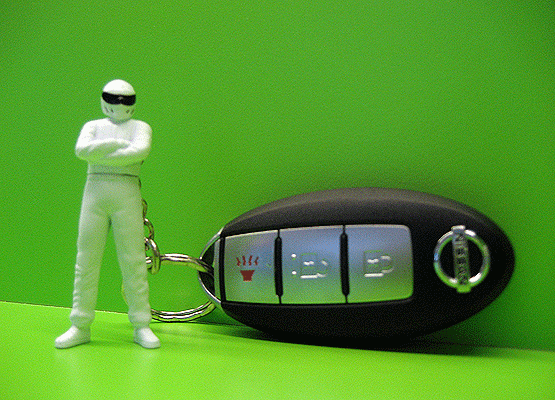

- The Stig Is Our Co-Pilot

- Adding Oil

- Too Small Inside. Or Is It?

- 7,500 Mile Service

- The Cheese Stands Alone

- Swoopy Design...Like a Bad '70s Hot Wheels Car

- IL Readers' Most Wanted

- What's the problem?

- Transformers

- Non-Syncro TimeMatch

- It's Not The Ride

- Truckin'

- Priorities, Guys, Priorities!

- Baby's Got Bass, Courtesy of Bose

- Fillet of Simulated Suede

- Training Wheels For Rev-Matchers

- Stuck in Gear

- Transmission Replacement

- Transmission Replaced

- New Clutch Break-in

- iPod Interface Video

- iPod Integration Sore Point

- There's a Zit on My Fascia!

- The 10,000 Mile Post

- The Opening

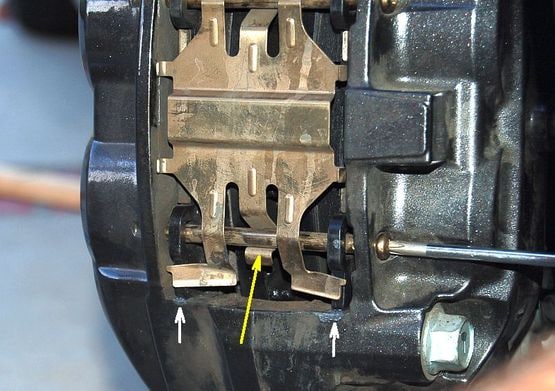

- DIY Brake Pad and Rotor Change, Part 1

- DIY Brake Pad and Rotor Change, Part 2

- Also a Liar

- Tire Noise

- Pitfalls of Street Parking

- Evening Drive

- Teen Boys and Hot Women

- The Conundrum

- The Dipstick Lover's Sports Car

- Damage Update

- Where is My Rear Wiper?

- Clutch Pedal Problem

- Easy on the Elbows

- Happy Birthday Mr. K

- Trunk Review Lite

- Can I Buy a Vowel?

- A Man's Sports Car

- Blood, Sweat and Oil

- Not Enough Junk In That Trunk

- Which Would You Choose?

- If It's Too Loud, You're Too Young

- Reprise

- A Relief To Drive

- Open Thread

- Pretty Pictures Edition

- Seat controls-the Good, the Bad...

- Unintended Activation

- SynchroRev Match Makes Editor Lazy

- Looking Back at its Inspiration

- All Wet

- It's a sexy sportscar

- Would You Keep Track of Its MPG?

- Gas Station Engineering

- Wondering What It Can Haul?

- The Sticky-Icky

- How To Annoy a Perfectionist

- Sweet Sixteen

- Better Than A Hot Hatch?

- It's No Honda Insight...

- You Write the Caption Two

- Our Favorite Caption

- Cement Truck Hell

- 15,000-mile Service

- This Car Doesn't Know Me

- Wraparound Look

- Easy

- Hits the Spot, But I Want the Roadster

- Go Ahead, Name a Better V6 in This Price Range

- Open Thread

- Noise

- Sound

- Nice Feature

- Nice Touch That's Holding Up Well

- NFS vs. GT5 vs. FM3

- Ten Things I Like About You

- More Than Expected

- Sound > Noise

- Bumped

- Wrap-Up

Introduction

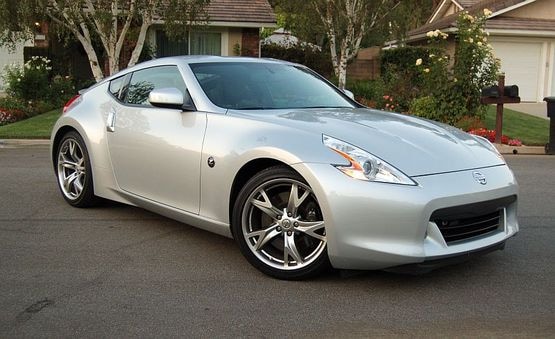

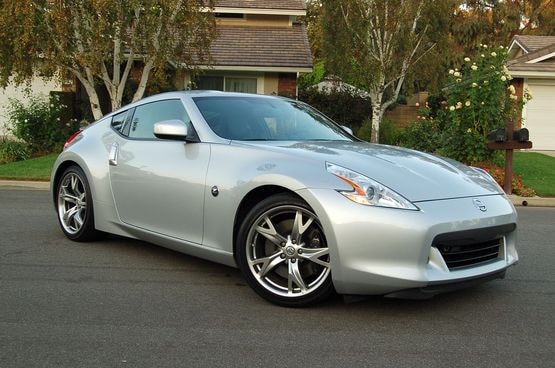

It's Edmunds' party for the all-new 2009 Nissan 370Z and Randy Rodriguez is walking around like he owns the place. It's not only because he owns one of the baddest Nissan 240Zs at this event. It's not even because his 240Z — one in a long line, because he's owned a Nissan Z-car as long as he's had a driver license — is painted in a color previously seen only on a Nissan showcar. No, Randy Rodriguez is walking around like he owns the place because as the designer of the concept car that spawned the production 2009 Nissan 370Z, he might have saved the Z-car (not to mention sports cars as we know and like them) from irrelevancy.

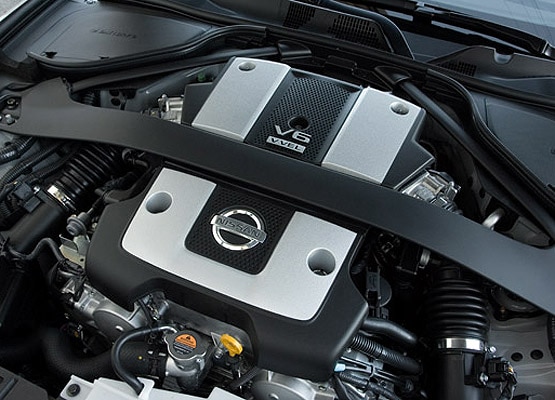

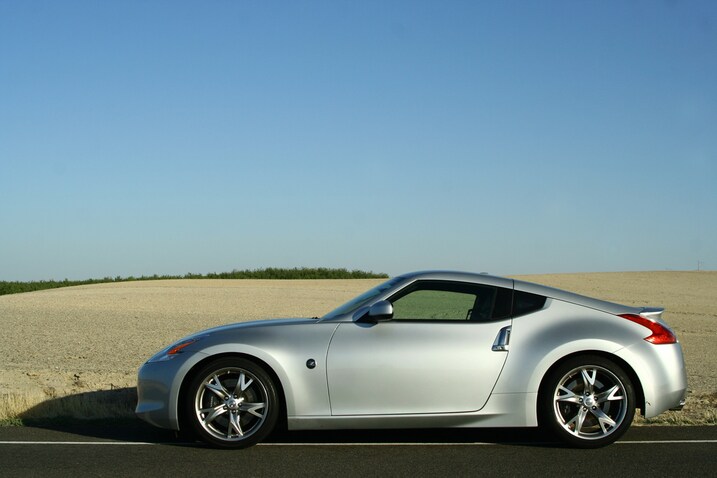

The weight of the world is upon the modern automobile. With innumerable laws, regulations, standards and specifications to meet, it's no wonder that cars today are getting bigger, heavier, duller and blander. But not the 2009 Nissan 370Z. Compared to the 350Z it replaces, the new Z is shorter, wider, lighter and powered by a new 332-horsepower, 3.7-liter V6 with variable valve timing and lift that's more powerful, too. It's a serious car, not just a stylish one.

It all sounds (and looks) great on paper, but a 12-month long-term road test here at Edmunds will validate (or invalidate) what our bar-napkin calculations hypothesize.

What We Got

When we began our talks with Nissan for the acquisition of a 2009 370Z for a long-term road test, pricing and specifications hadn't been released. We wanted a base car with the Sport package and the Technology/Navigation package. Turns out that such a combination doesn't exist. We could choose the base model car with the Sport package and get cloth-upholstered seats and a vacant cubby-hole in the dash, or we could have the Touring model with heated, leather-upholstered seats, a Bose audio system and Bluetooth, which offers the Navigation package as a $1,850 option.

While we debated our preferences for interior trim, there was no debate over the Sport package. It's a $3,000 option that we had to have. The $3 grand goes toward a set of slick-looking, lightweight, forged-aluminum 19-inch Rays wheels wrapped in wide Bridgestone Potenza tires, plus big brakes (14-inch rotors in front; 13.8-inch rotors in the rear) with four-piston calipers. On the driveline side, the Sport package adds a viscous-type limited-slip rear differential, while cars with the six-speed manual transmission like this one also include Nissan's new SynchroRev Match.

SynchroRev Match is Nissan's innovative feature that makes a manual transmission easier to use for the average driver. When we got our hands on one, Engineering Editor Jason Kavanagh took us through a detailed overview. "SynchroRev Match," he says, "is a feature that automatically 'blips' the throttle when the driver initiates a downshift in manual-transmission-equipped 370s. If you depress the clutch, lift off the throttle and move the gearchange lever to a lower gear, SynchroRev Match zips the engine up to precisely the right speed for that gear.

"The result? Perfectly smooth rev-matched downshifts every single time, and drivers that look like heroes." It's a clever idea that's so useful for everyone that we're surprised it hasn't appeared sooner.

Base or Touring, all 2009 Nissan 370Zs have the same engine, the 332-hp VQ37VHR, a DOHC 3.7-liter V6. Nissan's VVEL (variable valve event and lift) is similar to BMW's Valvetronic, one more strategy to control the volume of fuel that flows in and out of the combustion chambers and thus combines good power with good air emissions.

The new 3.7-liter V6 also produces 270 pound-feet of torque at 5,200 rpm, a number substantial enough that it helps get the Z-car out of the hole quickly enough to reach the quarter-mile in 13.4 seconds at 104.8 mph.

Even though we think more people will buy the Base model, the Technology package won us over just because we can't do without a navigation system. Those buyers interested in the Base car can still relate, while those looking for more information on the full kit won't be lost.

And so our new long-term 2009 Nissan 370Z wears a sticker price of $40,320.

Why We Got It

Like you have to ask?

With its wide, arched fender flares, low stance and menacing grimace, the 370Z is more pony car than pocket rocket. The new 2010 Ford Mustang is on the horizon and the new 2010 Chevrolet Camaro isn't far behind, and the Z-car will put their performance into perspective. Affordable sports cars have been around forever, but they've never been this good. They've never been this fast. And they've certainly never had this level of refinement.

The 370Z represents one of the finest examples of bang-for-your-buck you can find at any car dealership (even if we did load up ours with some non-performance goodies), and we'll see if "good for the price" makes it as compelling both against pony cars at the low end of the price spectrum and against pure sports cars like the Porsche Cayman at the high end.

Is It Refined Enough?

For 12 months and 20,000 miles, we'll be blogging about the daily ins and outs of the new 2009 Nissan 370Z. The VQ37's refinement has been in question since its debut, so how will we feel about it after a year? The aggressive suspension calibration and hyper-sticky tires that help the 370Z nail our slalom test at nearly 70 mph are certainly fun for freeway off-ramps, but will the Z-car prove to be a tolerable ride the rest of the way to work? And the last Nissan with a clutch that we drove for a long-term road test — the 2007 Infiniti G35S — was frequently ignored because of its awkward, grabby clutch action. Will the Z-car be friendly enough for daily use? Moreover, how will the Z-car's appeal shake out when our long-term garage now holds not just two examples of the 2008 Mitsubishi Lancer Evolution but also the 2009 Nissan GT-R?

Stay tuned to the long-term road test blog and let us know what you think.

Current Odometer: 1,410

Best Fuel Economy: 18.5 mpg

Worst Fuel Economy: 14.7 mpg

Average Fuel Economy (over the life of the vehicle): 16.1 mpg

The manufacturer provided Edmunds this vehicle for the purposes of evaluation.

Ever since I learned to drive stick I've been trying to figure out how to master the heel-toe downshift. I've practiced on every manual-shift car I get in, have asked many an editor to teach me and even got Edmunds Senior Automotive Editor Brent Romans to make a video running through the steps. But I can NEVER get it. When to blip? When to brake? When to move my foot off the clutch? Is my foot too small? I know, I overthink things.

But then we got the 2009 Nissan 370Z Touring in our fleet. Another editor suggested I give it a go since it has the very nifty SynchroRev Match feature that blips the throttle for you when you downshift. "You'll be able to hear when you should get the revs up," he said.

So lucky me had the Z this weekend. It's much easier to manage than our old Z which felt like its clutch pedal was a foot off the floor. In any case, sure enough when I downshift, the car automatically blips the throttle for me, making for a smooth transition to a lower gear. Neat! At first I loved it. I felt like a superhero racecar driver...but then I realized that since it does the job for me, I can never practice and can therefore never master that elusive skill.

Sure, there's an off button for SynchroRev Match but 1) with that technology readily available, will the Average Joe still be willing to suffer through the annoyingly awkward stages of the learning process to master the heel-toe downshift? And 2) where is the off button?

So the trip computer in the new 370Z is a little funky and those auxiliary gauges on the dash can be hard to see sometimes, but would you look at that tachometer?

I mean, that's how a tach in a sportscar is done. Big, clear and right in the middle. It seems so easy, yet all too often designers try to get cute and start shoving it off to the side in the name of symmetry. Stop it already, just copy this setup and call it a day.

Just take a look at the dials from Jacob's post below. Not bad for a sedan, but how much better are the Z's?

Deputy Caroline took this picture of the Nissan 370Z looking like the Cube is a growth on its nose.

I offer up "Dude, you made it come out my nose."

I'm sure you can beat that.

We'll post our favorite caption Friday at 4PM (Pacific Time).

Thanks to vacagrande for this week's favorite caption.

Others that made us laugh:

I should've never slept with that pathfinder (cx7lover)

He's my brother from another mother (louiswei)

It's not a tumor! (gooney911) and It's naht a toumah! (Murtman)

Do these wheels make my butt look big? (shladney)

Extra, Extra - Nissan engineers discover the wind-tunnel! (Before and after shots). (bizz1)

Z: Hey, Lil' Man...You're in my space. (johnnyr3)

And you can always get me with a Star Wars reference:

Cube, I am your father (gooney911)

What was your favorite?

My first real seat time in a 370Z came several months ago when we did our initial road test. I loved it and said so in my second opinion. Now that I've had a little bit more time behind the wheel, however, I'm starting to realize that as a daily driver, the 370Z might not be my first choice.

It's not the power, the ride quality or the funky gas gauge either. It's the interior room, or lack thereof. I just don't fit in the thing. Now granted, at 6'2" I'm a little taller than average, but still the 370Z feels tight even when you're properly adjusted with plenty of foot room.

It's a good setup when you're ripping a tight road, but getting into it after work with a computer case and gym bag in hand, the Z fills up real quick. Add to that a low seating position and tight shoulder room and the 370Z just doesn't give you much room to relax.

Is it enough to make me not buy it? No, it's still too fast in a straight line and too sticky in the turns for that, but it would be enough to make me reconsider some of its competitors like the new Mustang or Genesis Coupe. Those cars don't match up dynamically to the Z, but they are a little more comfortable.

I put close to 400 miles on our 2009 Nissan 370Z Touring over the weekend. Although it started with a few turns on Glendora Mountain Road , the rest of it was nearly all freeway. After all that, I am in agreement with Ed that the Z is pretty amazing through corners but not the most livable daily driver in this price range.

Ride quality is pretty good in the 370Z, even with the forged 19-inch RAYS wheels and Bridgestone Potenza RE050As (P245/40R19s in front and P275/35R19s in the back), but road noise is high. On several occasions, I instinctively reached for the volume dial when my boyfriend started to say something, only to realize that I was trying to turn the car down rather than the stereo.

Similarly, the seats are well-shaped for my 5-foot-10 frame and proved comfortable for 2-hour stints. Yet, there's no question that the 370Z's smaller size (compared to the 350Z) affects the seating position. The dash is right up in your face, and with no telescoping steering wheel, there's no escape.

Still, there are a number of details on the 2009 370Z that helped me overlook its compromises. For one, its size. At 167.1 inches long, it's almost 3 inches shorter than the 350Z. It feels compact from behind the wheel and it fits in small street parking spots. (Please note that I would never park it like this overnight — just for 30 minutes while at the farmers market.)

Another touch I like are the shelves behind the seats. The 350Z had a small, closable cubby back here, but I never found it very useful. Not so with these shelves. They're lined in felt and have a raised lip around their perimeter, so you can actually place something here with some assurance that it will stay put around cloverleaf entrance ramps.

Naturally, I put my purse on the shelf behind the driver seat, but the other shelf kept these dim sum leftovers from liberating themselves in the footwells.

That's our long-term 2009 Nissan 370Z Touring during a head-to-head comparison test with Ford's new and improved 2010 Mustang GT Premium complete with the optional Track Package. It was a fun test between two very capable 300+ hp, rear-wheel drive performance coupes. They even cost about the same if you're careful with the Z's options list.

We tested them on the track and on the street, and we hit more than one mountain road. We even shot video, which I happen to think is worth watch twice.

I won't spoil the outcome of this battle for you here, but I'm curious, which would you choose?

Comparison test: 2009 Nissan 370Z vs. 2010 Ford Mustang GT

I had to drive to the distant suburbs of Phoenix today in our 2009 Nissan 370Z. The trip started out in the usual fashion — I left late and felt rushed getting to a 6:30 p.m. dinner (made it in plenty of time, though). The navigation system didn't help matters by continually suggesting that I drive down to San Diego and use Interstate 8. See here, Nav Lady, I only use I-10 when I go to Phoenix. Finally, in Blythe, CA, she relented and we went on to Maricopa without incident.

The big surprise of the day was the 370Z's seat comfort. I sat in the driver seat for 7 hours and did not get kinked up, much less sore — a real feat for a Type A person like myself. It's interesting, really. These seats have a decent amount of adjustments, and the upholstery grips well through turns, but still, for this kind of money, it seems like there should be Recaros.

Still, 7 hours of comfort cannot be denied. I didn't even use cruise control.

By now you've all read our 2010 Ford Mustang Vs. 2009 Nissan 370Z comparison test. At the end of the day, the newly refreshed Mustang (a darn good car) put up a strong fight but ultimately fell to the sharper, more focused, better looking (yes, better looking) — but less functional Z car.

Before that test was ever conceived, we subjected our Long-Term 370Z to the usual set of performance tests. Follow the jump for full results.

Vehicle: 2009 Nissan 370z Touring 6MT

Odometer: 995

Date: 02/03/09

Driver: Josh Jacquot

Price: $40,320

Specifications:

Drive Type: Rear Wheel Drive

Transmission Type: 6-speed manual

Engine Type: 60-degree V6

Displacement (cc / cu-in): 3,696cc (226 cu-in)

Redline (rpm): 7,500

horsepower (hp @ rpm): 332 @ 7000

Torque (lb-ft @ rpm): 270 @ 5200

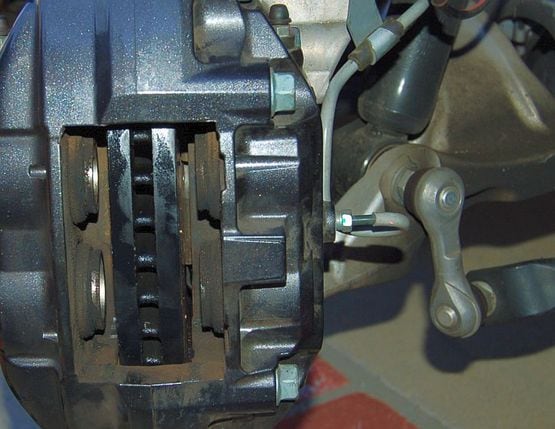

Brake Type (front): 14.0-by-1.26-inch ventilated discs with fixed 4-piston calipers

Brake Type (rear): 13.8-by-0.79-inch ventilated disc with 2-piston calipers

Steering System: Speed-proportional power steering

Suspension Type (front): Double wishbone

Suspension Type (rear): Multilink

Tire Size (front): P245/40R19 94W

Tire Size (rear): P275/35R19 96W

Tire Brand: Bridgestone

Tire Model: Potenza RE050A

Tire Type: Summer

Wheel Size: 19-by-9 inches front — 19-by-10 inches rear

Wheel Material (front/rear): Aluminum alloy

As tested Curb Weight (lb): 3,381

Test Results:

0 - 30 (sec): 2.1

0 - 45 (sec): 3.5

0 - 60 (sec): 5.3 (5.8 with traction control enabled)

0 - 75 (sec): 7.8

1/4 Mile (sec @ mph): 13.6 @ 103.2 (14.0 @ 101.0 with traction control enabled)

0-60 with 1-ft Rollout (sec): 5.1 (5.6 with traction control enabled)

30 - 0 (ft): 25

60 - 0 (ft): 105

Braking Rating: Very Good

Slalom (mph): 70.4 (67.1 with traction control enabled)

Skid Pad Lateral acceleration (g): 0.93 ( .89 with traction control enabled)

Handling Rating: Excellent

Db @ Idle: 49.2

Db @ Full Throttle: 82.7

Db @ 70 mph Cruise: 70.3

Acceleration Comments: 370 Z seems to like wheel spin off the line — and it's required to keep from bogging engine. We found at least 5,000 rpm works best. Get the clutch out quick or it will sink. Tranny still resists fast shifts, especially 1-2.

Braking Comments: Very good distance and pedal feel, but scored rotors aren't good. See below for details.

Handling Comments: (Skid pad) Limits are high but understeer is heavy as they approach. Coaxing the Z into tail-out goodness isn't as easy as I'd like. (Slalom) Superb grip & predictability make the 370 reassuring in fast transitions. It's shorter wheelbase, however, makes it slightly more spin happy than I remember from the 350Z. Overall, however, I prefer the new nimbleness.

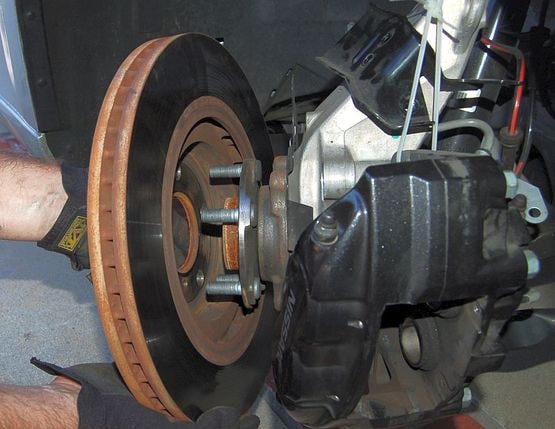

Let's take a minute to talk gauged brakes, shall we?

�

This is a picture of the front rotor of our Nissan 370z after brake testing. The car had 1,000 hard miles on it, but still, after the first two stops of 130+ feet, we knew that they were not bed-in enough for testing and began that process. The bedding-in process, according to our Engineering Editor Jay Kavanagh, "establishes a useful "transfer layer" of pad material onto the rotor, and should be done on any high-performance braking systems. It works like this — you perform several (ten or so) moderate stops in rapid succession, starting from ~60 mph to ~10 mph, then let them cool." The first stops we did combined with a shortened bed-in process resulted in some screaming hot (that's a technical term) pads which became abrasive and scored the rotors. Despite the looks, the pedal feels fine and the car came to a stop from 60 in only 105 feet.

My 36-hour, 900-mile Arizona road trip in our long-term 2009 Nissan 370Z Touring ended around 11:30 last night. Although I never had a chance to explore any interesting back roads with the Z, I am surprised by how much I still like it after hours on interstates and numbing desert highways.

Ride comfort is a big reason, because our sport-package 370Z is compliant to a level I never would have believed before this trip. This is not a compromised sport coupe. It's one I could live with everyday.

I've really warmed to the driving position, too. Although I previously complained that the new-gen car's shortened wheelbase has the dash up in your face, the setup turned out to be fine on my trip. I was comfortable behind the wheel, even though it doesn't telescope, and I liked how I was in finger's reach of the nav, audio and climate controls.

Average fuel economy for the trip was over 21 mpg, and I don't deserve any credit for driving conservatively on I-10. Instead, I chalk it up to the 18 speed cameras I passed in greater Phoenix (even without a front plate, I was careful) and low speed limits in the Maricopa area.

I checked the oil around 3,300 miles (on a level surface after letting the car sit 15 minutes) and it registered below the low mark on the dipstick. I bought a quart of 5W30 and added it in stages, but ultimately, the 370Z needed the whole thing. Given that the oil also looks dirty, the car will likely be getting an oil change soon. No surprise that it needs one, really. We've driven the Z hard.

Before spending the last thousand miles with our 2009 Nissan 370Z Touring, I'd thought that anyone who wanted parking sensors or a back-up camera on a sportscar had issues with spatial relations and parking in general. That might still be true, but I'll tell you this: After two weeks with our Z car, I'm still terrible at judging the rearward view.

This is exactly what I see when I'm belted into the driver seat and turn my head to look back. If there's someone in the passenger seat, that useless rear quarter window is blocked. In a crowded parking lot, my only strategy is to start backing up verrry slowly and hope that I see cross traffic before it's too late.

I actually haven't had any close calls in our 370Z, but if bumper sensors or a camera were optional on this car, I'd swallow my pride and order them.

Brace yourselves for the latest Long-Term Blog textcast, in which we tackle sausage, sportbikes, and the demise of the affordable sporting engine note.

Sadlier: So where's your $30k going. Base 370Z? Genesis Coupe 3.8 Track? 128i? Mustang GT?

Sadlier: Subaru Tribeca?

Magrath: 370Z. The Mustang's better than expected by a lot but I just don't like it. The seating position is too high and I think it looks dumb. The 128 is lame. I would constantly kick myself for not getting the turbo motor.

Magrath: Genesis Coupe is interesting but I don't like being in it. Great to drive but the steering wheel is lousy, the Infinity stereo's lousy and I think the car is ugly.

Sadlier: Huh. The Genesis Coupe's looks have actually grown on me. Plus the doors slam shut like my old prison cell — very similar to our M3. I seriously think Hyundai benchmarked those doors.

Sadlier: The problem with the Genesis is that the 128i basically matches its acceleration numbers, and it's more refined. I think I would grit my teeth and go with the 128i, horrendous ugliness notwithstanding. With apologies to the Tribeca.

Sadlier: ...unless a cold-air intake or something could fix the Z's gnarly engine note ("the coarse sounds and vibration of this V6 mean you have to grit your teeth and force yourself to keep the throttle floored past 6,000 rpm" — Engineering Editor Kavanagh), in which case, absolutely, sign me up.

Magrath: You'd pick the ugliness of the 128 over the engine note of the Z? I can understand picking it because of the Z's horrible road noise, but not because of the engine sound. You'd also be stuck with a back seat. I like that the Z doesn't give a backseat. The option of four seats just makes people think it's okay to ask for rides.

Sadlier: Yeah, backseats are overrated. Except that they're really useful. But you know, as far as the engine note goes, I tend to think that if an engine sounds like the Z's, it's because the engine team just couldn't be bothered to fix it. And I want my car's engineers to care about how my engine sounds.

Magrath: You know all they'd do is add a tumor-like snorkus to the intake, a la the F-150 — which has 4!

Sadlier: Four?!

Sadlier: Well, shoot, if that does the trick, then snorkus away. The snorkus makes the GTI's 2.0T sound good, and that's fine with me. The motor doesn't have to be authentically refined. I'm willing to be tricked.

Magrath: The Z's engine sounds like intake and valves going all crazy, that's what machines sound like.

Sadlier: I disagree. Some engines are just thoroughbreds. They can't help but sound good. Which, by the way, is why mentioning the Z in the same breath as the Porsche Cayman is absurd.

Magrath: And why pitting anything bang-for-the-buck-oriented against anything pure-performance-oriented is absurd. It's lose-lose. Want to compare Wal-Mart knives to Shun Elite? They both cut stuff. Go for it! Artisan-made Italian salumi to that tube of sausage you can buy at the deli for 48 cents a bucket? Sure!

Sadlier: Exactly. I mean, I can't say I was thinking specifically about preserved meats, but, yes.

Magrath: There will be people who get it, and then there will be people who say that the lower-priced item is good enough and the other is a waste of money. So it goes.

Sadlier: But you know, even cheaper sports/sporty cars used to sound pretty damn good sometimes. With the notable exception of the V8-powered Mustang/Challenger/Camaro trio, why do they mostly sound like crap these days?

Sadlier: Take that 1990 Miata we have downstairs [a special loaner from Mazda's garage]. I remember reading that the engineers painstakingly tuned the sound until they had just the right sporty roadster character. Fast-forward to 20 years later, and what have we got?

Sadlier: The 370Z, which sounds like a bear whose hibernation was rudely disturbed (as opposed to the old VQ V6s, the 3.0-liter versions, which had a classic turbine-like smoothness).

Sadlier: The Genesis Coupe 2.0T, which, like its Evo/Ralliart/Lancer 2.0 engine-mates, sounds like a vacuum cleaner.

Sadlier : Even Honda's ostensibly sporty VTEC fours don't sound good anymore. Civic Si is one of the better-sounding sporty things currently, and it's a distant echo of the old Integra GSR. TSX, totally boring, forget it — the '95 Accord EX 5MT sounded ten times better. Only the S2000 has that cool sound I'm talking about.

Sadlier : The '00s: the decade the affordable non-V8 automotive music died.

Magrath : But hiring engineers to tune a specific sound can't be cheap, and in the current automotive climate, short of exotics, what's the point?

Magrath : If you're in the market for a new car, the engine note isn't going to be a deal breaker. It may be a footnote in stories you tell later on, "aww, my old GSR sounded so much better...," but that story will always end with the classic going away and a new car, better in every measurable way, replacing it.

Sadlier : Well, call me a Luddite (it's been done before ), but with the Genesis Coupe 2.0T/Evo/etc., I think the engine note is a total dealbreaker. It quite literally sounds like a vacuum cleaner. Likewise the 370Z — the hibernating bear analogy is accurate, I'm afraid. They just don't sound like sports cars. Period.

Magrath : The 2.0T in the Genesis does sound pretty pathetic.

Sadlier : Put it this way. Imagine if a sportbike sounded like that. Dealbreaker, right? Why shouldn't we hold sporty cars to the same standard?

Magrath : Because sportbikes appeal to one person: the sportbike rider. And even those have been tuned down to acceptable levels lately — show me 10 bikes and I'll show you 9 aftermarket mufflers.

Sadlier : On the contrary, I think the sportbike sound appeals to anyone who likes going fast in things with wheels. There's no mistaking that sound for anything other than an engine that's designed to take you places really quickly. Whenever I hear one, it's like an instant gateway to a daydream about fast driving.

Sadlier : And when I hear the 370Z, I think of an angry bear.

Magrath : But a daydream is a far cry from a purchase.

Sadlier : True, I don't want to die, hence I don't buy sportbikes. But still, if I were designing an affordable sporty car, you know, I think there's a real opening in the market here. Give it a spine-tingling engine note, one that says "I am fast and special" to you and whoever's along for the ride, and that can only help its cause. Affordable non-V8 cars just don't have that anymore.

Sadlier : Though in fact they are (in the Z's case at least, and the Evo's) very fast and pretty special.

Magrath : But most buyers don't want to hear ANY engine noise — even ones who buy sports or sporty cars just want the looks and the concept of fast. They'll never push it. Engineers are tailoring cars to the lowest common acceptability levels and if a car is going to be full of dynamat anyway, why bother tuning the engine?

Sadlier : In the Z's case, they didn't dynamat jack squat. Though they should've at least covered the firewall with it so we wouldn't have to listen to that racket. That's what makes the G37 tolerable — they put a bunch more sound-deadening material on the firewall.

Magrath : One man's high tech and spine tingling is another fella's buzzy and strained. Who do you appease with your fancy engine note? The ricer crowd who thinks shrill is cool? The pushrod dudes who like the sound of stalling? Take the last gen G35 — the engine note was lackluster, but they tuned the exhaust to sound like the future and people loved it or hated it. No in-between.

Magrath : Hate = no sale. Ambivalence = possible sale.

Sadlier : Nah, I think it's a win-win proposition. Spend a few extra bucks and turn the vacuum cleaner or the angry bear into a special-sounding machine. You'll impress people who are eager to dismiss the car as "just a Hyundai" (in the GC's case) or cheap sausage (the Z).

Sadlier : And as for those who couldn't care less, well, I'm sure they won't mind driving a sporting car that actually sounds like one.

Sadlier : Follow Porsche's example — or BMW's, or Honda's with the old VTEC cars, or Nissan in the 3.0-liter VQ days, etc. — and lead the way. Flaunt your aural excellence. Set yourself apart.

Sadlier : Build it and they will come, Magrath.

Sadlier : A guy who built a baseball diamond in a cornfield said that.

The Inside Line crew's 370Z vs. Mustang GT comparo gave the win to the Nissan, but the Edmunds.com editors performed their own brief evaluation in the spirit of a high school debate. Which middleweight triumphs? That's for you to decide. Check it out here.

You may not have noticed, but our sport-package-equipped 2009 Nissan 370Z has got some serious wheel and brake hardware. The forged alloy wheels measure 19x9 up front and 19x10 at the rear. The corresponding tire sizes are 245/40R19 and 275/35R19s. This is on a sub-3,400-pound car with 332 horsepower, mind you.

For comparison, BMW's expired Z4M coupe, a car with a similar size/weight/power, rolled on 18x8s up front, 18x9s in the rear and 225/45R18 tires up front and 255/40R18s in back. Even the base Corvette (18s up front and 19s in back) has 245-width tires in front and 285s in back.

The Z's braking performance during testing was a little controversial, but in terms of specs — 14-inch rotors up front with four-piston calipers — there's nothing to complain about.

When it's standing still, the 370Z really looks the part thanks to those 19s, big brakes and wide tires. And with an as-tested 70.4 mph slalom speed and 0.93 g on the skidpad, it's got the numbers to back it up.

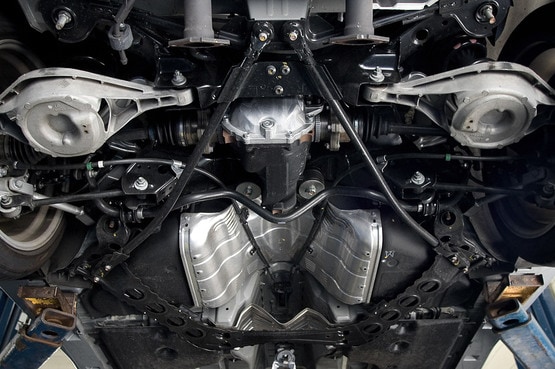

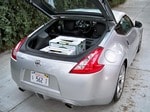

I love the way our 2009 Nissan 370Z handles so crisply, yet its ride quality is still relatively supple. Credit is certainly due to the car's stiff body structure, which Nissan says allowed it to tune the suspension to be more compliant. Just about everywhere you look, our 370Z has bracing. Under the hood? There's a suspension tower brace that spans the engine bay width and connects to the firewall. Open a door and you'll see the thick beam behind the seats. Nissan wasn't messing around.

As you have perhaps noticed, the 370Z lacks the 350Z's infamous exposed rear structural brace. I remember reading that Nissan had "inverted" it. I was curious to see where it went, so I went looking.

I removed the rear carpet and cover. If there's an inverted structural crossmember here, I didn't see it. Perhaps it's considered the raised part of the body structure ahead of the spare tire that spans the width of the rear suspension towers?

By the way, you can see that this is where the spare tire is located. The subwoofer for the Bose audio system is also here, nestled into the wheel. I unscrewed the securing clamp and lifted the subwoofer; I'd guess it weighs about 10 to 15 pounds.

Compared to the 350Z, Nissan's 370Z press release claims that there's "a new front suspension cradle to reduce front body lateral bending," new "rear structural reinforcements" and "an underbody "V-bar" to help reduce rear lateral bending." I peeked underneath the rear of the car and did see what appears to be the additional structural bracing, including the "V-bar." It'd be interesting to get our car up on a lift at some point to see this stuff in more detail. Or maybe not, if standing underneath a car looking at nondescript metal bits isn't your thing.

Anyway, I'm continuing to enjoy the Jack-be-nimble handling characteristics of our 370Z.

Our 2009 Nissan 370Z has satellite radio, and when I'm driving I'll occasionally listen to radio Faction's afternoon DJ, Jason Ellis. Jason has this ongoing theme where callers recount their feats of awesomeness and he then judges them on whether or not they are admitted into a nirvana-like "awesome world."

I mention this because our Nissan 370Z would be an excellent candidate for Brent's Sports Car Awesome World. It's got tidy dimensions, great handling, a quality interior, impressive as-tested numbers and, to my eyes at least, a good-looking exterior. But there's one thing that's going to hold it back from gaining entry.

The not-so-awesome thing: the V6 engine. Now, this is a capable engine that's surprisingly torquey and tractable. And there's certainly nothing wrong with having 332 hp on tap nor a 0-60-mph time in the low 5-second range. But this latest 3.7-liter version makes the 370Z a Tin Man from the Wizard of Oz — it has no heart.

The V6's coarseness and vibration at anything past 5,000 rpm are just plain bad. Really, when you're hard on it, that last 1,500 rpm to redline is not enjoyable all. (And this is the part that's supposed to be the most exhilarating for a small-displacement sports car!) Meanwhile, there's no aural passion whatsoever. Sadlier described as sounding like a bear — err, OK, maybe. The engine note is OK when you fire it up but then it's all downhill from there. There's this distracting engine whine at lower rpm and none of the characteristic 350Z exhaust warble heard from either inside or outside the car.

I wish I had video for you, but I don't. But I found this video clip on YouTube of a 370Z with an aftermarket exhaust. There might be hope for disgruntled 370Z owners.

As it stands, though, the larger V6 is the one thing I think Nissan flubbed. Make the new Z's engine exciting to rev and listen to, and the car gets into Brent's Sports Car Awesome World.

I used to have a sportbike or two a while back. Riding on more than one occasion, I wouldn't know what gear I was in — I wished for a gear indicator display. Well, today, several sportbikes have such a feature.

And it's especially nice on a motorbike because of the sequential 6-speed gearbox, the close ratios, and the extremely flexible engine. If you weren't paying close attention, it would be easy to forget where you were, particularly in the middle of the gearbox (3,4,5).

The car where this gear indicator display would come in handy is the BMW 135, because it too has a close ratio 6-speed manual gearbox (but non-sequential) and an extremely flexible engine. Several times I've lost track of what gear I was in.

The 370Z on the other hand, has nicely spaced ratios and, although the engine can rev, I can't imagine it being called motorbike-like — it doesn't zing up. You get a lot of feedback from the engine and exhaust note, too.

So do you need the gear indicator on the 370Z? Well, it's nice to have, and doesn't take up almost any space in the meters at the bottom of the tacho. It's not like it's a head-up display that is blocking your view or something. And it shows you if you got the occasionally hard to get reverse.

Next to the gear indicator is a display showing if the Syncrorev match system is on or not (JK said it remembers last position selected.) Which is nice.

But I guess this won't matter in the future, anyway, when the New World Order in Washington forces us to all drive hybrid/electric/fuel cell vehicles with CVTs.

We sure had fun when we put the 2009 Nissan 370Z against the new Mustang GT.

Pricewise, the cars were pretty evenly matched. And both hit 60 mph in 5.2 seconds and run the quarter in 13.5 seconds.

But there was a definite victor. And that winner, my friends, is the Car of the Week.

With less than 5,000 miles on the odometer, our long-term Nissan 370Z has already taken it on the chin. Repeatedly.

Good news is that the lower plastic chin guard is doing its job. Despite the fact that the plastic is starting to look shredded at the corners, there's no damage to the Z's Brilliant Silver paint.

We knew when we threw a reveal party for the all-new Nissan 370Z prior to the Los Angeles Show that there would be a lot of excitement around this car.

Now is your chance to ask us whatever you want to know about the new Z.

Have you driven one? Write your review in the comments section.

Sportscars usually get a bad rap for poor visibility. It's the price you pay for a car that looks cool, but the complaints pour in anyway.

The 370Z is not immune. It has a low seating position and a shallow greenhouse, but as you can see here visibility isn't all that bad. Rearward blind spots are the biggest issue here. A good adjustment of the mirrors is all it takes to cure that issue though.

There's not much you can do about the small rear window, other than be careful of course. I don't find it particularly troublesome personally. The Challenger suffers from the same problem and all it takes is a little extra caution when changing lanes and backing up. Seems like a small price to pay for a stylish design.

Today history was made in our 2009 Nissan 370Z Touring: it turned 5,000 miles old during its tenure as our Car of the Week.

But wait, there's more. Can you guess where it happened?

Hint 1: The person represented by the place took the world stage in 1969 — the same year the original Z-car came to America.

Hints 2 and 3 are the photos that appear after the jump. Can you find the significance of each?

Back in November we ran our first Full Test of a 2009 Nissan 370Z. That test car was a short term loan, it was red, and, unlike our long-term test car, it wore aftermarket, Nissan developed oil and differential coolers. During extreme usage, especially track use, oil gets hot. If the VQ in our 370Z senses things getting too hot — which can happen in as little as 10 minutes — it sends the car into limp-home mode limiting revs to only 5,500. Limiting this car to 5,500 is like limiting Barry Bonds to bunting, we've never experienced limp-home mode, but we never want to. "If you plan on doing any track driving" our contact at Nissan said, "you'll need one."

So we made some calls and got one and had it installed by Nissan of Santa Monica while the car was in for its 3,750-mile service.

Follow the jump for the full shake-down.

The unit we got was recommended by Nissan as it was designed for the 370Z by Nissan Motorsports. This is not the upcoming NISMO unit, nor will you be able to buy one or have it installed from your local Nissan dealership. The cost of the kit you see here is $780.

Installation was handled by Nissan of Santa Monica working closely with Nissan's North American operations and took about 4-hours at a labor rate of $115/hr. That's $460 for labor and $780 in parts. Total cost for oil cooler and install: $1,240.

Overheating oil was a problem on the last generation Z, too, so this isn't much of a surprise. One of the by-products of bigger power and bigger displacement is bigger heat production. Plus, this new car is stupid fast and with that SynchroRev Match system we're bouncing the revs all over the place. $1,240 might be a hard pill to swallow, but have you priced a new 3.7-liter VQ? We haven't and don't want to.

The 370Z, on the premium maintenance schedule, requires an oil change — which already had to be drained to install the cooler — and a new oil filter. They inspect a bunch of other stuff, too, but it's little more than an oil change. Our service advisor at Nissan of Santa Monica remembered us fondly from our recent $2,009.67 GT-R service. He gave us a hand-out on this one, told us to bring the GT-R in again soon and comped the 370's 3,750-mile service cost.

So now we've got new oil and a new oil cooler...which way's the race track?

The suspension on our 2009 Nissan 370Z is pretty straightforward. It's got upper and lower control arms and a coil-over shock.

Here you can see what is called a high-mount upper arm. The hub carrier (aluminum here) is huge, and it stretches upwards to locate the upper ball joint high in the fender well. This provides a very large moment arm to counteract side loads generated while cornering. And a large moment arm reduces the forces seen at the upper ball joint. In turn, the upper arm and the body attachment points won't see high loads either, so they can be lighter and stronger.

You can also see how the upper arm slopes down dramatically to the rear. This is called anti-dive geometry, and depending on the angle it can reduce or eliminate brake dive. It would seem that instantaneous caster would increase as the loaded side's upper ball joint moves back during cornering, and that should increase self-aligning forces and generate feedback in turns. But none of the textbooks I own delves into that aspect

Some might call this a double-wishbone front suspension, because it has a one-piece lower arm, too. But a wishbone is either A- or Y-shaped, and this one is L-shaped. It's better to describe this as double control arm suspension.

You can also see that, once again, a forward caliper placement results from a rear-mounted steering rack.

The stabilizer bar link and spring/shock assys (center) mount some ways in from the lower ball joint (left), so neither are 100% efficient. It looks like a 0.65 motion ratio or thereabouts.

But there is something unique going on here. The upper stabilizer link end and the and the lower shock mount bolt to the lower control arm in the same place with a shared bolt.

Moving on to the rear, we can see that this is a multilink design.

Multilink is a catch-all designation that applies when you don't use double control arms or a strut. But links can only hold tension and compression along their axis, so you need many (multi-) of them to orient the wheel.

The 370Z has an upper y-shaped control arm and three links. You can see one of them sprouting behind the brake caliper.

You can aslo see ventilated rear brake rotors and a 2-piston fixed brake caliper. The stabilizer bar is buried deep in the background of the picture, it's end-link attaching about halfway along the upper arm. The twin-tube shock absorber mounts directly to a protrusion of the hub carrier (aka knuckle or upright) for a 1:1 motion ratio.

Here you can see two of the lower links, a black steel one and an aluminum one that has been bloated to double as a lower spring mount.

For fun, I weighed the wheel and tire assemblies and made a few notes while they were off.

Front: 51.5 lbs 19x9 47 mm offset*

Rear: 57.5 lbs 19x10 30 mm offset*

5 x 114.3 mm (4.5 in) bolt circle.

Mind you, these are Rays Forged aluminum wheels, so the wheels themselves shouldn't be overweight. The wheels and tires are simply 19-inch monsters and they're super wide. There's a lot of material here.

Here he is, and you'll find him in every Z-car.

Yutaka Katayama is the reason the Z-car exists. It was his idea and he made it happen. Nissan started the whole sports car thing from Japan in the mid-1960s, and the 1970 Datsun 240Z put both Nissan and the Japanese car industry on the map. Since then, other Japanese car companies have entered the sports car business, but soon or later, they all quit. Acura, Honda, Isuzu, Toyota — they all quit. Even Nissan tried to quit. But the spirit of Yutaka Katayama always reminds Nissan that it's mean to be more than just another car company from Japan, and then the Z-car bubbles up to the surface again.

And now the spirit of the Z-car could save Nissan and the car industry again.

Fifty years ago, there were two strong personalities at Nissan, a sales guy and an advertising guy. Katayama was the advertising guy, a brilliant yet sensitive guy who liked British sports cars and occasionally pursued the traditional Japanese cultural pursuits of flying kites, painting landscapes, and, you know, talking to trees. Needless to say, the sales guy soon had him exiled to America, where he hoped his rival would disappear from view.

Instead Katayama built Datsun (as the Nissan franchise in America then was called) into a sales powerhouse, personally canvassing every town in America and turning used-car dealers and lawnmower repair shops into Datsun franchises. He made Datsun the most important Japanese brand in America, a signature of quality and innovation instead of cheap imitation. For his trouble, the sales guy chased him out of the U.S. company by the late 1970s and put his people in charge. Datsun quickly lost its lead in the sales race to Toyota and became a follower, not a leader.

But as times grew tough for Nissan, the spirit of Mr. K always brought it back from the brink. The 1990 300ZX Z32 was the lead vehicle in a new corporate initiative in vehicle dynamics, a real GT car instead of the Thunderbird clone that the previous generation Z-car had become. When poor sales of sports cars thoughout the car industry led to the Z-car's demise in the U.S. in 1996, a Z-car concept came to the surface again in 1999. And when the 350Z was revived in 2002, it symbolized the Nissan's resurgence with new financial backing from Renault.

And every time, Yutaka Katayama was called out of retirement and asked to provide his blessing. He even became the focus of a notable advertising campaign from which these pictures are taken.

The Z is still the coolest car at Nissan, GT-R notwithstanding. In fact, the new GT-R actually started as a Z-car made serious, a kind of Porsche 911 GT3, until the present, all-wheel-drive big car prevailed in planning sessions. Everyone at Nissan still wants to work on the Z-car project simply because it's always been a car that aspires to greatness.

Unfortunately Mr. K, who turned 100(!) on February 19, isn't really part of the process any longer. Incensed that Nissan uprooted itself from the headquarters he built in Los Angeles for a new corporate culture in Nashville, he's once again in a kind of exile. But as Nissan fumbles once again for a new identity in America, it's clear that it needs him back simply to remind itself that there's more to making cars than slashing costs, playing three-card-monte with a fistful of car badges and one or two platforms, and hunkering down in the bunker with the accountants while the war for the future of the automobile takes place all around you.

In fact, the whole American car industry could stand a little Mr. K. A little aspiration, a little sense of striving for excellence, and a little feel for the emotion with which Americans regard the automobile would go a long way toward making us all face the four-wheel future with more confidence.

Mr. K knew from the start that that the automobile has the power to transform the future. He saw it happen in Japan as he grew with his country through the 20th Century (he is 100 years old, after all). And anyone who has ever heard him speak knows that Yutaka Katayama understands that the automobile is a gift of personal mobility that can make our lives better, not worse. So maybe we should quit apologizing for the car and just get on with the business of making the future.

Where have you gone, Yutaka Katayama?

A lonely nation turns its eyes to you.

I'm obsessed with constantly checking traffic on Google Maps so I love it when cars have navs that show you what's happening on the freeways. Our 2009 Nissan 370Z has one such nav which shows if traffic is flowing, slow or stopped according to whether there's a green, yellow or red line. But one detail that stands out to me is the Sigalerts of actual accidents, as depicted by an icon of an upside down car accompanied by a quick detail of the situation.

BTW, here's a shot of the nav screen at night. Notice how clear the layout is. And you gotta love that day/night button.

I wanted to do a video where you could hear what our 2009 Nissan 370Z sounds like when it matches revs on its own but instead I got a video with a lot of road noise, something clicking against my camera and a quiet engine.Sorry! But at least you can see how smoothly it transitions between each gear with the SynchroRev Match. And, yeah, no hooliganism here. Just me pulling to a stop. Woo. And, looks like I need to clean my camera lens.

This weekend was a scorcher with temperatures in the mid to high 80s and that was just at 10 in the morning! So when I had gone out to brunch and parked our 2009 Nissan 370Z in the hot midday sun, I was dreading slipping back into its darkly swathed cabin.

Before I got in, I even opened both doors to get a nice cross breeze going and then sunk into the seat with a premature "Ow!" but there was no need. The faux suede was, as expected, comfortable but the leather on the sides was only just warm against my bare skin. The amazing part was the cabin itself was only warm as well as opposed to the searing heat that I had initially expected. And all that dark gray on the dash? I could actually rest my hand on it without suffering any burns.

Is this special technology? I know BMW has technology to keep its leather 20 degrees cooler than usual leather but I couldn't find any mention of something like this on the Nissan site. Another editor supposed it was the tinted glass that helped filter out the infrared light but whatever it was I was grateful.

And I also loved how quickly the air-conditioner cooled down the warm cabin. Really made the hot days bearable.

By the way, here's how we enjoyed the beautiful weather this weekend: a leisurely cruise in the Santa Monica Mountains.

Our long term 2009 Nissan 370Z is quite racy.

Details that contribute to this feeling are the oil pressure and voltmeter gauges (along with a digital clock) on top on the dash, just like old-school race cars.

The Z also has well-styled vertical outer door handle with smart entry. The handle is slightly awkward to use. Below are pics of two different strategies you could use to open the door, and both of them are slightly clumsy. But it's not enough of a problem to negate the sexy looks of it.

Speaking of sexy, I think the back end view is the best angle of this car. Look at those wide, muscular fender flares covering the massive 275/35WR19 rear tires.

Compliments to Nissan for continuing to make a sexy, affordable, true sports car, when others have given up.

A couple of weeks ago when we had a bout of hot weather in L.A., I praised our 2009 Nissan 370Z's dark interior for miraculously remaining cool despite the car's being left outside during the hottest part of the day. I forgot to mention, however, that at first glance I couldn't find out how to turn on the A/C to further cool things down.

I mean, looking at the above picture (taken from my POV in the driver seat), can you find the air-conditioner button? Of course I'm only addressing those who aren't Nissan car owners.

Yup, there it is. Under the fan button. Of course from the driver's POV that script is concealed by the protruding button itself.

Naturally, this won't be an issue to actual owners of this car. But maybe this is a good way to keep "friends" from wanting to borrow your Z this summer. "Sorry, it doesn't have an A/C. You can look for yourself."

Whenever I drive our long-term 370Z, I'm led to an overwhelming question:

Why don't I want this car?

I should. I'm smack dab in the middle of the target demographic. Twentysomething guy, likes speed, cares about handling, doesn't care about practicality. But the Z turns me off every time. It makes me think of all the cars I'd rather have at this general price point. S2000. 1 Series. 328i. Genesis Coupe 3.8 Track. G37. RX-8 (and I don't even like the styling). Camaro SS (and I haven't even driven it yet).

Yes, the Z will mop the test track with most of the above, but I don't care. Cars are about more than just the numbers, and that's where the Z falls short. The quality of its interior materials is extraordinary (better than the G37, I'd say), and its ride is surprisingly supple, but road noise is raucous even at moderate speeds. The 3.7-liter V6 makes big power, but it sounds like a Frontier on steroids — it's so loud and thrashy above 5,000 rpm that I keep it out of that range unless absolutely necessary, which is something that should never be said about a sports car. The tires have mondo grip, and body roll is barely perceptible, but the Z feels big and burly in the twisties, more fullback than wide receiver.

So what if it performs like a champ on track day? Sports cars should make me want to take the long way home. This one doesn't.

I tripped my way into the 370Z last night after getting my foot caught on some loose plastic door sill trim. Upon further inspection, I realized that almost all the trim pieces that cover the bottom of the door sill are loose. Disappointing to say the least, especially given the fact that our 370Z doesn't even have 6,000 miles on the clock.

Well, over the weekend my fears were realized. No, a cat wasn't squashed, but when I was slowly backing out of a space at 7-11 a dude slapped the side of my car and gave me the finger through the passenger window. He was walking up to the store directly in my blind spot, I never saw him.

The next day I was backing out of a spot super slow, nervous I was going to get another finger of vengeance. My windows were down, leaning out when I could, looking through the windows, in my mirrors, just trying to get the best look around my car as possible. As my passenger side window cleared the rows, there stood a lady with a stroller giving me the stink eye.

%^$&#!!

There are different ways to do things, then there are incorrect ways to do things.

Today, I ink up my WRONG stamp for the 370Z's fuel gauge, which consists of 16 little lights that go out to indicate its running low on dino swill. I don't like digital fuel gauges and this is one of the worst, since it becomes difficult to read when directly in the sun. This entire digital unit looks like what the 80s thought the future would look like. Or a Borg eye implant. Or that Simpsons episode when Lisa gets married in England and Big Ben's face has been replaced in the future with a digital clock blinking 12.

Sorry Nissan, you are incorrect, and with apologies to Depeche Mode, WRONG.

Nissan has at least one thing figured out with the new 370Z — the seats. Notice that their center sections are fabric — synthetic suede, actually. I had a chance to drive our long-term car on a track last week and, despite the fact that the seats don't fit me perfectly (none do), I wasn't flopping all over and trying to hold myself in place. This is because the "leather" seats which come with the Touring Package actually have fabric on the seat bottom and backrest. On full-leather seats I would have struggled against physics.

Also, see that center bolster between where the driver's legs would be? That's a gimmick. Worse yest, it's a legacy gimmick from the last Z which does nothing. Nissan should do away with it. Otherwise, this is a good setup for hard driving with ample adjustability and good driver retention.

Every once in a while an automotive technology will come along that has me yearning for it to trickle down into other cars. Sometimes it's a small thing (satellite radio) and other times it's a game changer like the Synchro RevMatch manual transmission found in our long-term Nissan 370Z.

The ease of making rev-matched downshifts differs based on pedal placement, throttle tip-in, driver's foot size, position of the moon, familiarity with the car, and of course, driver skill. I don't claim to be a heal-toeing maestro, but I find our M3 and Mini Cooper S to be incredibly easy ... the Challenger not so much.

But none of that matters in the Zed (which is spelled as such for my fellow Canadians out there). Once I got beyond the initial trepidation of dropping the clutch without matching revs, I found myself downshifting a lot more. At traffic lights, I'll go down through the gears just for the hell of it rather than coasting in whatever gear I was in. Sure, there could be a "lost art" element to this new technology, but I think it makes shifting your own gears more fun.

Now if only it was attached to a more pleasant engine. So here's hoping that the remaining purveyors of manual transmissions develop their own Synchro RevMatch. As Howard Hughes said 1,988 times at the end of The Aviator, "it's the way of the future."

In a fortuitous twist of fate, I scored the keys to out 370Z last night, and in the brief time I spent behind the wheel I have some observations as well as a simple maintenance issue.

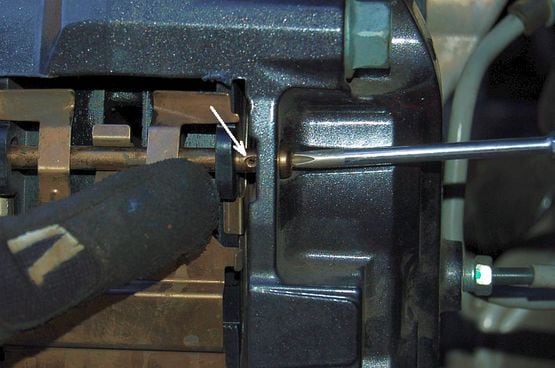

Brakes:

Accelerating off the line with a bit more aggression than needed, I noticed that the "BRAKE" light appeared in the left instrument pod, then disappeared a few seconds after feathering the throttle. This was repeatable at every green light I encountered. Fortunately, I've come across this before in one of my own rides (when pulling serious lateral G's instead of longitudinal, though). My diagnosis: slightly low brake fluid level.

Another issue that caught my eye was the "VDC OFF" light remained lit during my morning commute. The VDC relies on the brake system to maintain stability, so I'm assuming this is related to the low brake fluid level. The light went away after I shut-down and restarted the engine (maybe it's powered by Microsoft?).

Pop the hood, find the brake fluid resevoir, and there's it is — the level's right between the high and low marks. I'll bring this to the attention of the Mikes and hopefully this is the actual culprit of the intermittent BRAKE light.

Blips and Revs:

I've spent the better part of the last decade honing my heel-toe downshift craft, and, I can confidently say, "Yeah, I've mastered it." I'm also fairly proficient at traditional, and more complicated double-clutch downshifts in vintage racecars. With that self-aggrandizement out of the way (bow down to the master of soon-to-be obsolete skills!), I am completely enamoured with the Z's Synchro RevMatch system.

I challenged myself to do it better and failed. **sigh** I've been replaced by a machine...but wait, something's not adding up here. A good heel-toe downshift requires a strong throttle blip that shoots the tach past the point of the matched revs of the next lowest gear. The clutch isn't re-engaged until after the revs begin to fall.

Here's what I discovered about the Z that makes me feel better about being beat by a computer: With the Synchro RevMatch off, I executed the typical heel-toe and noticed that the revs didn't fall as quickly as I'd expected. Using my normal downshift tempo, I was dumping the clutch while the revs were too high. So the solution was to pause before clutch re-engagement (not at all racy), or attempt to blip precisely to where the revs are in the next lowest gear (difficult, but not impossible).

I now contend that Synchro RevMatch is necessary in the Z because of the drivetrain's inability to affect a proper heel-toe downshift without the aid of a computer. That's my story, and I'm sticking to it, anyways.

Had some business over the Memorial Day weekend with motorsport photographer Jesse Alexander at his studio up in Carpenteria and it turned out the 2009 Nissan 370Z was my ride of choice.

We looked over some pictures he'd taken of the very Mercedes-Benz 300 SL that won the 1952 24 Hours of Le Mans. After its racing days were done, it was rebodied as a street car and Alexander drove it on the street in Europe as he drove to racing circuit to racing circuit, taking some now-famous pictures of racing.

Not a bad way to spend a morning, especially as we ate lunch down the street at Sly's. James Sly is pretty famous in his own right, a French-trained chef who cooked for a CART Indy-car team during the days of glamorous hospitality at the Indy 500 in the early 1990s. At the same time, he also wrote pretty insightful stuff as the technical editor of a small magazine devoted to European cars. Now his steakhouse in Carpenteria is where everybody in Santa Barbara who knows anything about cars comes to eat. Some of Jesse Alexander's most famous images hang on the walls.

But for all this stroking around with notable ex-racing guys, the 370Z didn't prove to be the right ride. Sure, I really get the Z-car and even spent Saturday morning looking at the Nissan 350Z that Steve Mitchell drives in the Redline Time Attack series, a high-tech piece with a 580-hp Cosworth-built Nissan V6 that's probably the fastest Z-car in America. But the 370Z proved to be just terrible on the freeway to Santa Barbara. About 90 minutes of driving at a time proved to be as much as I could stand.

It's the tire roar. It's bad enough when you're driving on asphalt, but the grooved concrete of freeways in Southern California really makes this car a penalty box on any kind of real trip. And it's not the tires themselves; it's the lack of acoustic refinement from the car. It makes the 370Z seem like a cross between a dump truck and a National Guard Humvee. As near as I can remember it, the 350Z was a whisper-quiet limousine in comparison.

I sometimes find my truest opinion comes forth when I have to quickly answer the question "so, what do you think about it?" There's no chance to be wishy washy or be swayed by nit-picks (wrong fuel gauge) or pet likes (the excellent iPod interface). Oh, and try explaining Synchro RevMatch to a neophyte in 10 words or less.

Such a situation happened this weekend at a barbecue in Griffith Park when a fellow attendee asked (after first pondering what I was doing taking a picture of my car), "So, what do you think about it?"

"It's really rough. Rough ride, loud, the clutch and shifter are stiff. You have to really manhandle the thing. When you're driving aggressively, it's great, so if you do a lot of weekend driving or maybe a track day, go for it. But I don't think many people would want to drive it every day. It would get old. I'd rather have a BMW 1 Series or maybe a Hyundai Genesis. Looks cool, though."

Hmm, so that's how I feel.

Our long-term 2009 Nissan 370Z got a new key fob today. Thought you might like to see it.

This morning I drove our long-term 2009 Nissan 370Z about 40 miles south of our Santa Monica office to visit MD Automotive in Westminster. MD is where we do all of our dyno testing and we had a couple of supercharged toys to test this morning.

Anyway, when you're testing cars there's always plenty of standing around waiting, so I decided to check the Z's oil level. And guess what?

It was low. So I poured the majority of a quart of 5W-30 (Yes, I checked the manual.).

Total cost? $212. (The oil was just a few bucks, but I spilled some of it on a very expensive shirt.)

Before this week I've only driven our long-term 2009 Nissan 370Z (or any 370Z) for short bursts. One night at the most. No drive longer than 30 or 40 minutes.

And my impression has been; great car but too cramped inside. Reminded me of the third generation Mazda RX-7. Loved driving it, but the feeling of claustrophobia was just too much.

Now I know better. I just spent the bulk of this week in our Z, three days, three nights and several hundred miles of driving. And my impression has changed.

The 370Z isn't too small inside. After a couple of days I acclimated to the Z's interior dimensions and sight lines. The feeling of being stuck in an elevator with a dozen folks washed away and I really began to enjoy the car.

Don't misunderstand, it still doesn't feel as large inside as the bigger 350Z, but it is not longer a deal breaker for me.

I also realized that the black interior of our test car must contribute to that cave feeling. I'll bet a 370Z with a lighter interior feels right from day one.

(The photo really has nothing to do with this blog, I just liked it.)

Last Friday I surprised our local Nissan dealership, Nissan of Santa Monica, by showing up with our 2009 370z. It was about due for an oil change (couple of hundred miles early if you must know), and that broken door sill panel was really bothering me.

The car was ready only a couple of hours after we'd dropped it off. This service was expected to run about $90, that includes the oil change and a bunch of inspections, but came up slightly short at $78.04.

Parts for the broken bits were not in stock and are on order.

The only surprise came at the end. Our service advisor let us know that the brake pads are low and will need to be replaced. Remember back when we first tested this car? When the brakes cooked on only two stops and scored the rotors? Well that's likely a factor in such short pad life. Also a factor is this car's speed, weight and attitude. It gets run pretty hard and the brakes get used harder than do, say, the brakes in the Focus. Pads are about $80 and we're thinking of saving a couple bucks and doing this one ourselves.

Since I'm low man on the totem pole when it comes to the long-term car clipboard, chances are that I'll usually end up with the Smart or the Jetta TDI. Not complaining but it's just funny to see what consistently gets passed over by the editors.

But I've noticed that our 2009 Nissan 370Z has joined the other two at the bottom of the barrel more often. And last night, it was the only car left on the list. Meaning, someone actually picked the Smart Fortwo over the Z. Wuuut?

Curious why this happened, I first asked someone at the top of the list why he skipped over the Z. "I saw the GT-R and the Z and I took the GT-R," said Karl Brauer matter-of-factly. OK, well maybe a fellow low man would be the person to ask. So I asked Automotive Content Editor Warren Clarke who is two above me on the list and who actually picked the Smart.

"I don't like its visibility and it's hard to get out of," he said of the Z. "It's a good-looking car and if I was doing something tonight where I needed a good-looking car I would have picked it. But I'm just going to the grocery store. So I don't want to have to worry about backing out of a space and not being able to see [in a crowded parking lot]."

Other editors, most with longer commutes, have said that they don't like its harsh ride for their everyday needs.

As for me, I like fast cars so yay.

I took a good long look at our long-term 2009 Nissan 370Z over the past weekend and realized something: the car's body lines simply don't work for me.

The problem is more subtle than overt, and it's really only noticeable on profile or rear three-quarter angles, but the swoopy hind quarters, combined with the exaggereted taillight design, looks like something out of my 1970s era Hot Wheels collection. Among my cars is a chrome (literally chrome) Porsche 911 with varying floral print designs going over the hood and roof. Maybe it's the 370Z's vague 911-esque shape, plus its silver color, that furthers the effect, but when I look at the swoops and sweeps of its body I can't avoid thinking of that toy car.

And yes, I did think that Hot Wheels toy was cool...when I was 7.

We just published the results of our Readers Most Wanted Awards and the 2009 Nissan 370Z and 2009 Nissan GT-R cleaned up, winning two categories each. That means these two cars took four of the 15 awards.

The BMW 128i also grabbed a spot on the list, which essentially means three cars in our long-term fleet are favorites of our readers. Plus, several recent long-term blog alums took honors. Readers also voted big time for the Honda Accord, BMW X5, Toyota Tundra, Ford Mustang and BMW 3-Series.

You know, sometimes we take flack for this blog not having cars our readers are interested in. Um, hello.

It's true — our long term Nissan 370Z sits near the bottom of the pile in terms of desirabilty here. It is frequently one of the last test cars chosen and more than once sat unloved at night 'til the next morning. It occupies the same metaphorical space as... the Smart?! What's the problem? These items, I believe:

1. The ride is hard

2. The interior is small

3. The clutch and shifter aren't the greatest

4. It seats only 2

I refute these issues with:

1. It's a sports car

2. It's a sports car

3. True (but both aren't as bad as our LT Audi S5)

4. It's a sports car

One must make certain sacrifices when owning a sports car, but the benefits outweigh these.

The 370Z possesses great, quick handling, excellent steering feel, and a decent powertrain. And although I'm not in love with the exhaust note, it's OK.

It's the only true sports car in our long term fleet. (I consider the GT-R a GT; the name is GT-R.)

The big problem for the most of the people here is the seating capacity. Most of our staffers have friends or family to accommodate, and a 2-seater won't cut it for them.

For me, it's really fun to drive, and becomes even more enjoyable when you push it hard. It's in the top 5 in fun-to-drive for our long term fleet. The sedans, even the Evos, don't compare.

I was even going to sign it out for this weekend. But I may have to cart some people around...

Oh, nevermind.

Nissan has made a big effort to improve the apparent quality of the Z-car's interior, adding a lot more architectural elements, upgrading the quality of the upholstery and trim, increasing the number of features, and multiplying the number of storage areas.

The trouble is, there's just too much going on here for me. Instead of operational efficiency, what we have here is aggressive conceptual complexity. It's like watching Transformers from the front row.

For all the justifiable criticism leveled at the interior of the 2003 Nissan 350Z, I think I prefer this treatment. Sure, the doors are trimmed by featureless expanses of black plastic, but the presentation of the key elements is far better, even though the basic architecture is clearly similar to the 370Z. The 350Z's three instrument dials on the top of the dash were a real design breakthrough at the time, and I still prefer their use of multi-function electronics (including tire pressure and lap times) to the all-inclusive multi-function readout on the left side of the 370Z's dash, which manages to make even fuel level a mystery.

Sometimes good design is about utility, not just stylistic excess. Given the choice between the GT-R execution of the 370Z and the plainness of the original 350Z, I pick the 350Z.

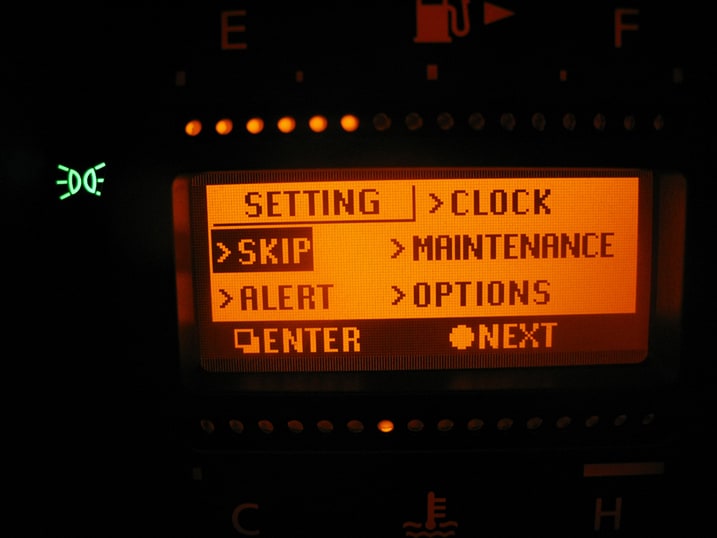

As with my colleague Mr. Takahashi, I enjoy rev-matching on my own, but like him still have to admit that the Z's Syncro RevMatch is pretty cool.

But if Nissan can offer this ground-breaking technology, why don't they have what I'll call Syncro TimeMatch? I'm talking about the two time displays (a stand-alone clock in the upper pod and one in the nav/audio screen) that aren't matched. I've seen other cars with redundant time displays (VW and Audi come to mind) that are synchronized so this strikes me as rather odd here. And yes, I adjusted the clock after I posted this gripe...

So we've been trying to figure out recently why our 2009 Nissan 370Z doesn't get more editorial love, and I keep hearing negative comments about the ride. "Rough." "Hard." "[Insert lewd comment here]." With due respect to my perhaps prematurely geriatric colleagues, I beg to differ. This Z has got one of the most supple sports-car rides I've ever experienced.

I aimed the Z at every rut and pothole in sight on my way to work this morning, and I failed to elicit anything I'd call "impact harshness." The Z's ride is firm, taut, controlled...but rough? Hard? No way. There's a BMW-like refinement in the way this car traverses broken pavement. In fact, I'd say it's more BMW-like in this respect than our 135i — a car that no one (well, other than me) has ever spurned on account of its harsh ride. As for the Evo MR, which has no shortage of suitors in these parts, the Z rides like a Lexus by comparison.

The Z's got issues, yes. The ride isn't one of them.

During my time in our 370Z, it managed to do nothing but confuse me. I thought liking this thing would be a slam dunk. You see, I like coupes. I like sitting low. I like sports cars. I like the way this car rides. I like the stereo. I even like the way this car looks.

But...

...for some reason, I just wasn't getting it. I knew what I liked about the Z, but I couldn't put my finger on what I didn't like. Then, with great relief, I figured it out.

I'd rather have the truck in which this drive-train belongs; the Nissan Frontier.

"Put in a CD with the engine soundtrack of a 'Vette," Romans advised me Thursday afternoon as I headed off on a camping trip to Big Sur. "And bring earplugs for the road noise."

In a characteristically pithy 18 words, our sage Senior Automotive Editor had summed up everything that's seriously wrong with the 2009 Nissan 370Z.

All this car needed was for someone with clout to swoop in during product testing and say, "Hey! Priorities, guys, priorities! This is a sports car, so why doesn't it sound like one? And it's all well and good that the interior is nicer than a G37's, but why does it have more road noise than an '87 Pathfinder?!"

If Nissan takes care of these two issues, I want one. Because after 800 miles in the Z this weekend, I've realized that I'm on board with pretty much everything else.

Note the qualifying phrase "pretty much." The Z does have a few other foibles that are worth mentioning. To wit: the Bose stereo is unimpressive with a CD and downright awful with an iPod, the shifter grinds too easily on quick 1-2 upshifts and 3-2 downshifts, and while I still say the Z's suspension is supple by sports-car standards, the short wheelbase and minimal suspension travel conspired to beat me up a bit over the 5 Freeway's rapid-fire expansion joints — so I can understand why there have been some complaints about the ride.

But the rest of this car is so good, so thoughtfully designed and expertly executed, that I don't really care.

Steering: wired-to-your-brain responsive at all speeds, yet confident and composed on the highway.

Body motions: tightly controlled, but with just enough roll that you can feel the car take a reassuring set as it rockets out of corners.

Engine: awesome V8-like tractability at low rpm. Reminds me a lot of the e46 M3's similarly powerful inline-6, actually, except with some extra bottom end and a little less high-rpm kick (or maybe it's just that the Bimmer sounds a whole lot better up there).

Interior : this deserves its own post, but in a nutshell, the attention to detail in the Z's cabin is simply remarkable for a sports car at this price point, from the stitching running through the center stack and console to the soft-touch dash, signature knee-pads and suede-like padded armrests.

Styling: I still don't dig the jagged headlights and the gaping maw, but this is hands-down one of the most interestingly styled cars on the road.

Moral of the 370Z's first year of production? Fix the engine note and Dynamat the hell out of the floor and wheel wells, and all that "budget Cayman S" noise will start to make a lot of sense.