1997 Mazda MX-5 Miata: What's It Like to Live With?

Read the latest updates in our long-term road test of the 1997 Mazda MX-5 Miata as our editors live with this car for a year.

What do you want to know about?

- Project Miata Lives

- You Said Knob

- List of Quirks

- Bugeye

- Glass versus Plastic

- Kraftwerks Supercharger Install, Pt. 1

- Knobless

- Kraftwerks Supercharger Install, Pt. 2

- Too Small for a Carry-On?

- No Soundtrack Needed

- Dripping But Driven

- Stoptech Stainless Brake Lines and Fresh Gear Juice

- The Lid

- Old's Cool

- Refined Yet Potent

- The Roof and Other Impressions

- Getting a (New) Grip

- Kraftwerks Supercharger Kit Meets Three Dynos

- Momo Wheel Gory Details

- Rear Window Defogger

- More Praise For Supercharging

- Personal Hygiene

- Yipes, Stripes!

- A Case for the Soft Top

- Mottle-y Trunk Lid

- Flying Under the Radar

- That's a Lotta Roadsters

- Happy Wheels

- Alignment

- Palomar Perfection

- The Wheel of Death - Before and After

- And Another Great Thing About Wheel of Death?

- Boots

- A 6UL Experience

- Aftermarket Is Not MySpace for Cars After All

- My Favorite Flavor of M

- Track Tested

- Seat Fixed...Finally

- How The Grip Stacks Up

- Seats are Good!

- HVAC Mode Slider Stuck

- Flyin' Miata Clutch And Flywheel

- 130,000 Miles

- Sorry, Tubby

- Deja Vu Cockeyed Gearshifter

- Seriously Fun City Car

- Positives and Negatives

- Adding Some Character

- Just Out of Reach

- Water Tight

- Could the 1997 Mazda MX-5 Miata Beat the 1985 Porsche 911 Carrera?

- No. There is Another.

- Riders on the Storm?

- Rotrex Acceleration Tested

- Minimal but Manageable

- Not the Usual Valet Parking Report

- Well, This is Awkward

- Look! It's an Engine!

- Need to Keep an Eye on That Oil

- Meaty

- For Blips

- More Room Than Our 911

- In Praise of Analog

- Ping

- Gimme Lightness

- School Bus?

- Blackbird Fabworx GT3 6-Point Roll Bar

- Blackbird Fabworx GT3 6-Point Roll Bar, Part II

- Roll Bar And Visibility

- The Beauty Of Dual-Purpose Cars

- The Beauty Of Dual-Purpose Cars, Pt. II

- The Beauty Of Dual-Purpose Cars, Pt. III

- The Beauty Of Dual-Purpose Cars, Pt. IV

- The Beauty Of Dual-Purpose Cars, Epilogue

- Wrench-Turning Update

- Young Dad Approves

- Sticky Belt

- Needs A Pull Strap

- 20th Century Relics

- Curing The Overheating

- Workaround

- Less Grip Please

- The Next Level

- Lash

- How About This for a Project Miata?

- Tuned on Forza

- Telltale

- Killin' the Wiggle

- Not for the Squeamish

- Room To Stretch Out

- We Meet Again

- I Guilty

- What The Heck Is This?

- A Look Underneath

- Back In Action

- Everything We've Done So Far

- The Other Downside to Being Low

- The Little Guy

- Affordable Excellence!

- Not Quite House Trained

- What Year Would You Get For A Project Car?

- Limited Practicality For Me

- Works Well In The Mountains

- Tuned By JKav

- Now That's a City Car

- The Three-Pedal Dance

- Where's the Reading Material?

- Now That's a Racket!

- Capable

- Long Rod BP Conversion And Nerdery

- Wait, What?

- JE Pistons Forged Side Relief Slugs In The House

- The Fork

- Hate That

- The Case for Analog

- Clean Cars Run Better

- Not For Me

- What Flashing Brights via Pop-Up Headlights Looks Like

- Seat Time

- Rattlecan

- Will It Fit?

- Master of the Obvious

- Self Tech

- The Seven Year Itch - Part One

- An Appetizer

- Green Vs. Yellow

- The Seven Year Itch - Part Two

- Its Life Flashing Before My Eyes

- Not Immune To Fuel Cost

- The Poster Boy of Compact Space Parkers

- Things To Like

- Another Reminder This Is a Driver's Car?

- Totally Convincing

- In The Zone

- Plate Spotting

- Slide Right In

- Keegan Engineering Head And Porting Tech

- Kumbaya

- The Door Bars

- The Steering

- Role Reversal

- Shut The Buzz Up

- Exfoliated

- KINOD Gathering

- Rattle Patrol

- Valvetrain Tech

- Rattle Patrol, Driveshaft Edition

- Trip Out, Man

- Two Screws and A Twist

- +1

- Assembly By Keegan Engineering, Pt. I

- Mil.Spec Connecting Rods

- Assembly By Keegan Engineering, Pt. II

- Blackbird Fabworx Is Replacing The Seat

- Blackbird Fabworx Is Replacing The Seat, Pt. II'

- Electronic Surprise

- Too Hot

- It Helps To Be Slim

- Less-Speedy Getaways

- Younger Brother

- Pro, You Say?

- Pie Hole

- DIY NB2 Coil On Plug Option

- Rotaries Are Good For Something After All

- Chasing The Squish

- To Laguna and Back

- Screeeal

- 140,000 miles

- Aftermarket Seat Tips

- Ride Quality

- Aftermarket Seat Tips, Version Two

- Door Bar Conflicts With Dead Pedal

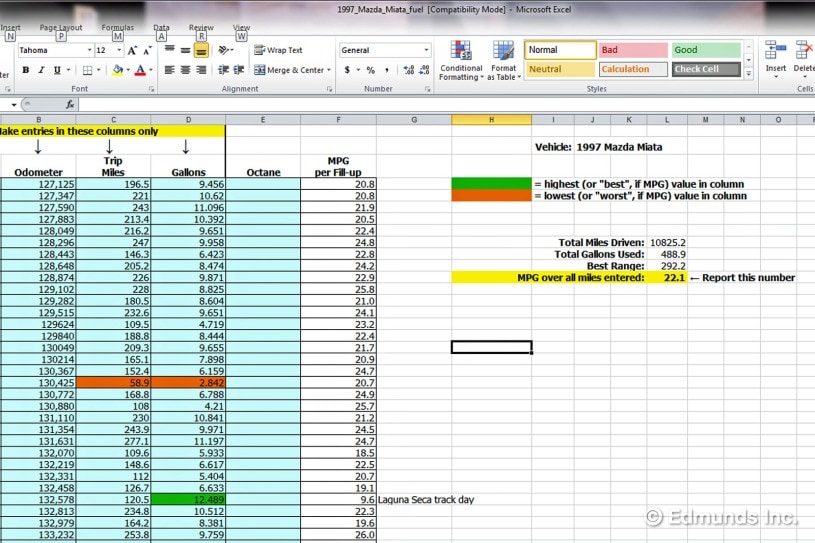

- Fuel Economy Update for January

- Two Valve Stems, But Why?

- Fuel Economy Update for February

- Saturday at Laguna Seca

- Sunday at Laguna Seca

- The Drive Home

- Thanks

- Synapses

- Racing

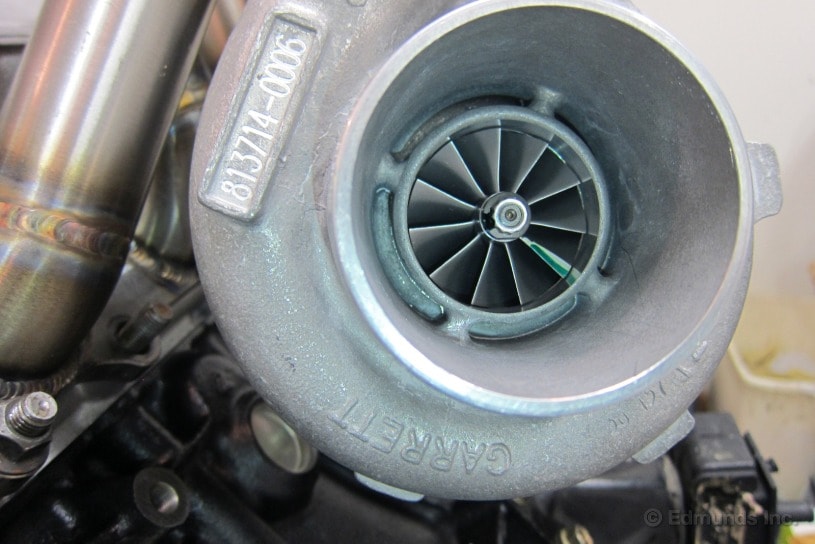

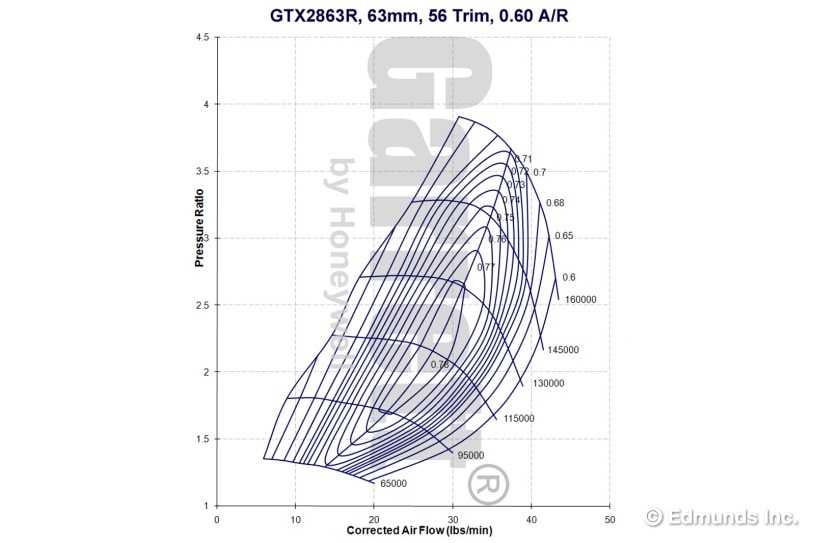

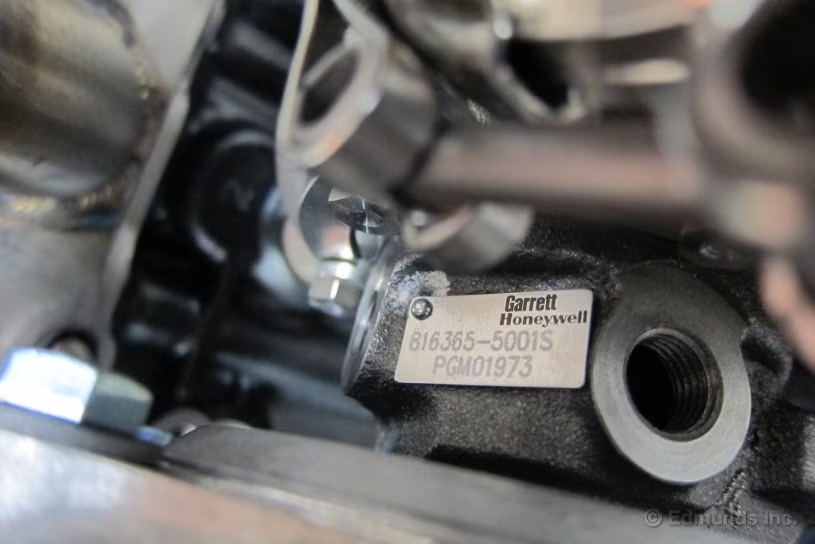

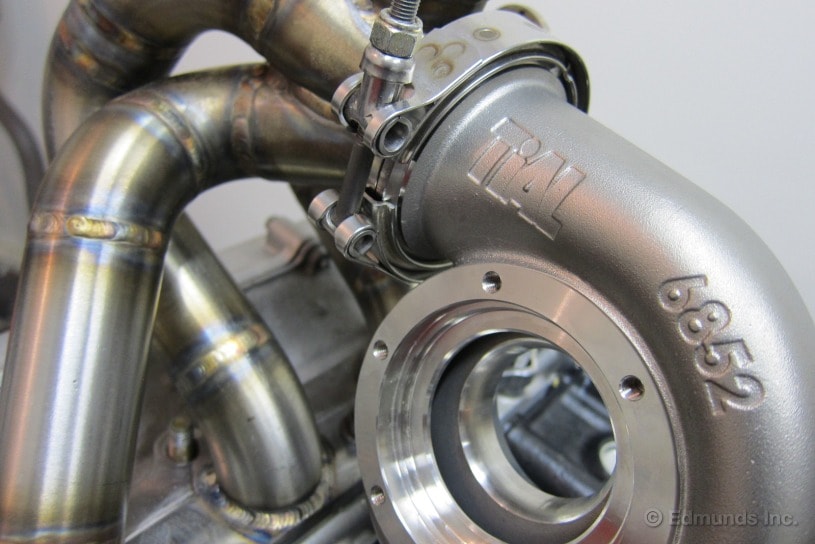

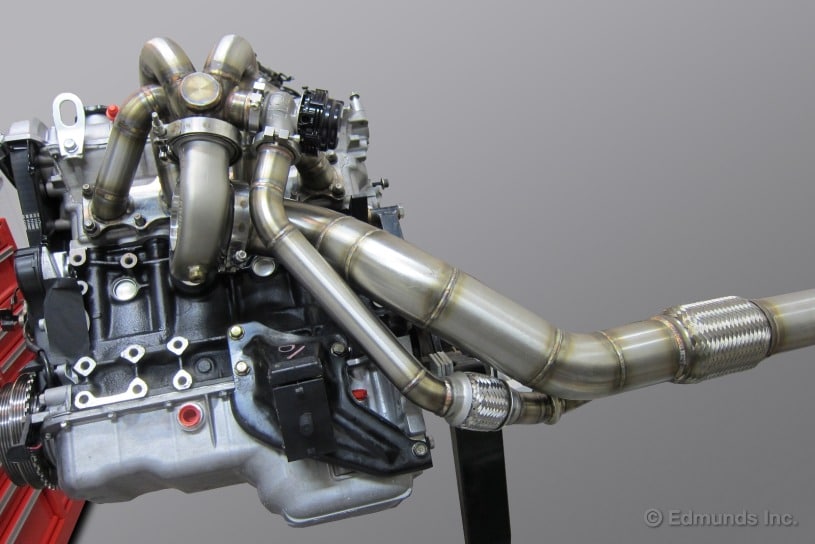

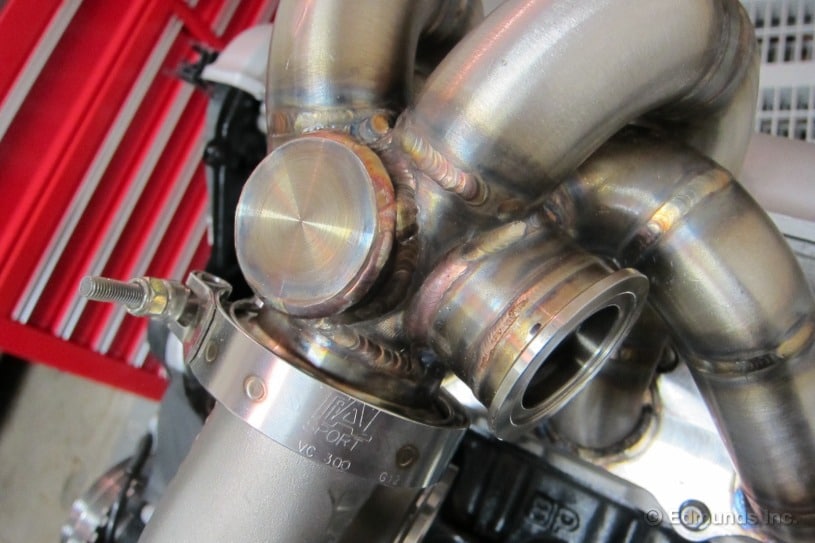

- Turbo Conversion With Garrett And TiAL Sport

- TiAL Sport Turbine Housing And Wastegate

- BHJ Dynamics Crankshaft Damper

- Check Engine Light

- Pulling the Codes

- The Catalytic Converter Is Dead

- Replacement Cat From Moss Miata

- Fuel Economy Update for April

- Chassis Stiffness

- Power Restored

- Fuel Economy Update for June

- Fuel Economy Update for September

- Speaker Distortion

- Busted Air Conditioning

- Engine Update

- Hide-And-Seek With the Seatbelt Latch

- Aftermarket Seat Is a Hug Machine

- Exiting the Roll Cage

- Problem. Solution.

- Close To You

- Fuel Economy Update for October

- Still

- Fuel Economy Update March-ish

- Holding Cups

In 1994, Mazda introduced that nadir of Miata-ness, the special edition M-Edition, which persisted like a lingering sore through the '97 model year at which point Mazda mercifully euthanised the concept.

Essentially loaded Miatas with different paint, trim and hideous chrome wheels, the M-Edition was that shameless money-grab by automakers — the badge and sticker job. M-Editions were the poodle chariots of Miatas. The wine-and-cheese version. They were given names like Fifi by the kind of people that name their cars.

They're also a goldmine for hardcore Miata enthusiasts.

Say what?

If you're befuddled, good. And I swear I'll tie this in to Project Miata, but you'll have to hit the jump first.

Being loaded, all M-Editions packing a manual gearbox also came equipped with a Torsen limited-slip differential. Meaning that unlike other trim levels, there are no questions or guesswork when you find one for sale in the classifieds or craigslist — stick equals Torsen.

And being the range-topping frilly-frill version, M-Editions tended to be bought by affluent (read: older) buyers that maintained their cars well and drove them only as hard as they needed to get to bingo night on time.

It turns out being asspacked by a Blazer was a blessing in disguise for Project Miata. The insurance settlement worked out very nicely, especially once I located a one-owner 1997 Miata M-Edition to replace the totaled white '94. This froggie had the optional ABS, a clean title, no damage of any significance and an integrated poodle harness. I might be lying about that last bit.

The fact that the owner was asking just $2000 made it an easy decision — we bought it on the spot several weeks ago and swapped over the bits from the white car when time allowed. So far that includes the suspension (FatCat Motorsports coilovers, Racing Beat stabilizer bar, 949Racing endlinks) and nearly-new service items including upper wishbones, ART hubs, R/LE tie rod ends, plus Stoptech 309 brake pads.

With 125k miles on the clock, this bass-boat green Miata has 50k fewer miles than the white car and was obviously treated better. Still, it's a used car, and it turns out some older drivers can't hear, and the butt-dyno of their inner ear ain't what it used to be. During my test drive this one pinged at part throttle and pulled hard to the right at speed on throttle and hard to the left off-throttle.

Fortunately, those are easy fixes. A compression check showed that the pinging was benign, and one rear tire was responsible for the pull since the differential can't tell the difference between turning and when its simply dealing with mismatched tire diameters. Once I put on the 14" Dunlops Star Specs we had lying around, it tracked straight and true. The 949Racing 6ULs will go on once I get the fenders rolled.

What's that? STFU and tell you why it's on the dyno in the lead image? Right, then. The gentleman behind the wheel is one Oscar Jackson, proprietor of Kraftwerks Performance Group, and it's being baseline dyno tested as part of its Kraftwerks supercharger kit installation.

Lots more to come. Enjoy your holiday, you crazy kids.

Uh huh huh huh.

Well one of you did (jstandefer, to name names) when you asked if our "new" Miata still had its Nardi shift knob. Follow the jump to see what I'm talking about.

To the left of the above photo is the Nardi piece that came special on our M Edition Miata. A Nardi knob it may be but it looks like a high school wood shop project, and a bad one at that. As soon as he could, Kavanagh swapped that Nardi nonsense with the knob from our original Miata, which is pictured on the right.

As for the steak knife brake lever, well, Kavanagh has decided to leave that in for the time being.

Anything else you'd like to see us swap out of the interior?

I love our new Project Miata: 1997 Mazda MX-5 Miata. It doesn't have that grindy 2nd gear nor the zombie interior of the old one and I don't feel grimy after sitting in it. And some of the quirks this one does have aren't that big of a deal but I'll just list them here.

1) A loose bolt behind the driver seat that clunks around, especially during acceleration and braking. Apparently you have to put the top down to get at it and since this top is a bit more involved than the old one — zippers, buttons and straps — no one has bothered.

2) Aftermarket radio has an annoying "don't forget me" chime after you turn the car off. I'm probably the only one annoyed by this though.

3) Molting steering wheel, but I hear that may change soon.

4) ... Actually that's all I got.

The interior is in pretty good shape. The previous owner took great care of it. No tears or mystery smells. And like the older Project Miata, this is just so much fun to drive.

Driving this car home at night, it's kind of a surprise to see the popup headlights floating there on the Miata's hood. When the Miata was first introduced for 1990, it was kind of a big deal to have popup headlights on such a small, affordable car.

Of course, you can see what the consequences might have been otherwise, as the Miata could have looked just like the 1958 Austin-Healey Sprite MK I, the famous Bugeye Sprite, of which 48,987 rolled out of the old MG plant before the more conventional Mk II appeared.

Popup headlights were introduced by Gordon Buehrig's Cord 810 in 1936, then Harley Earl copied them for his Buick Y-job concept car in 1938. The 1963 Corvette Stingray popularized popup headlights. Lotus also was an early adopter, and I remember a field of unsold Lotus Elite Type 75s at Lotus East in Millerton, New York, sadly winking with one headlight up and the other one down because their vaccuum-operated systems had leaked.

Plenty of cars had popup headlights during the 1980s, but as DOT regulations about headlight height and positioning relaxed, the design fell out of fashion. Only Corvette guys seemed to notice when the C6 ended the whole popup thing when it was introduced with conventional exposed headlights in 2005.

These days popup headlights just seem wacky, but it's kind of fun to see the Miata get all animated when it opens its eyes at night and becomes a tribute to another cheap yet incredibly influential sports car of long ago.

A common gripe for first-generation (1990 to 1997) Miatas (and many other older convertibles for that matter) is the plastic rear window. These tend to get yellowed and/or scratched up in time, reducing rearward visibility and in the process making one's Miata look like an aspiring hooptie. The upside of the flexible window is that it allows one to quickly drop the top — just unfasten the header latches and flip the top back.

Our '97 has a replacement top and the former owner opted for a glass rear window. The downside is that when you go to lower the top you must first unzip the rear window (glass doesn't like to fold) to allow it to drop down flat and then you flip the latches and flip the top down. If I were replacing the top on my own first-gen Miata, I'd gladly take the trade-off to get a perfectly transparent back window that won't eventually look like a cat mistook it for a scratching post or a dog mistook it for a tree.

And how are things going on the Miata's modification front you may ask? Pretty darn good. Stay tuned as an update is forthcoming.

When it comes to modifying cars that are well-seasoned like Project Miata, our 125k-mile longterm 1997 Mazda Miata, it helps to begin at the beginning. Go back to basics.

Oscar Jackson, owner of Kraftwerks Performance Group, had reminded me of this before we even met in person to install the company's Rotrex supercharger kit. I made a mental note of it. Thing is, my memory is spongelike — a few things soak in but there are a lot of holes.

Our well-maintained, strong-running, no-oil-burning, issue-free Miata appeared in normal working order, especially as it was completely stock and previously owned solely by a well-to-do senior gentleman. I'd earlier made sure the ignition timing was correct, and the engine made as-new compression numbers, plus the car drives with as much or more pep down low as these things ever did. Pretty much a best-case scenario for bolting on a forced induction thingie, right?

Yeah, that hole-y spongelike thing. There was one thing I didn't check, and we found out what it was when we threw it on Kraftwerks' Superflow chassis dyno for a baseline performance check. Oscar immediately noted something was amiss. Peak power was down quite a bit compared to other stock Miatas he'd tested and, more tellingly, power after peak nosed over more aggressively than it should. Come to think of it, it did feel tepid in the upper reaches of the rev range...

We both suspected the cam timing was off. Pick up a well-used car and it's a sure bet that many, many people — with varying mechanical skill levels — have mucked about with the greasy bits.

In Project Miata's case, the last mechanic to change the timing belt was a primate of some kind and he buttoned it up with the intake cam off by two teeth and the exhaust cam off by one tooth. I like orangutans and all, but their attention to detail in mechanical matters could be better.

Once the cam timing was re-set to stock, another dyno check showed our Miata was right on the money for peak power and picked up power everywhere else. Dynos rule.

Now we can throw on the Rotrex supercharger with confidence.

The What?

Kraftwerks' Rotrex supercharger is not a traditional Roots blower or even a traditional centrifugal supercharger. Okay, it is a centrifugal supercharger (we'll shorten this to CS for brevity's sake) in that it has a radial outflow compressor wheel just like that of a turbocharger.

Rotrex's twist on the CS is the high drive ratio (12.7:1) of its planetary

gearset

traction drive (it employs rollers, not gears), which allows higher shaft speeds than those found in a conventional CS. The Rotrex's shaft speed capability means it doesn't need to rely on as large a compressor wheel to generate meaningful boost. The smaller compressor wheels better match the engine's breathing characteristics and package better to boot. Also, the planetary drive system doesn't have the gear whine of conventional CSs.

The smaller wheel means the Rotrex doesn't have the banana-shaped boost profile often associated with CSs, either. Instead the Rotrex's boost characteristic is basically a straight line that rises from zero at idle and peaks (at around 6 psi in the Miata) at redline.

This low-boost approach (plus the fact that the whole shebang is self-contained) makes the Rotrex well-suited as an affordable bolt-on kit to a stock engine. If this approach sounds like deja vu, it's probably because you remember the popular Jackson Racing blower kits from years ago which took a similar tack.

Yes, Jackson Racing was Oscar Jackson's business before he decided to retire several years ago. It was the Rotrex supercharger that compelled him out of retirement to form Kraftwerks.

Naturally, 6 psi isn't going to make huge dyno queen numbers, but the Kraftwerks' 160-ish whp will be a nice bump from the stock 100-ish whp.

More later.

When I got into our revamped Miata last night I was slightly shocked. The Nardi knob was no more. I read about the transplant on our blogs and heard the chatter around the water cooler. Ok, I get the symbolic gesture of taking the shift knob from our recently departed Miata and transplanting it to this one. I know the powers that be prefer the plastic over the wood. But I hadn't seen it with my own eyes.

When I opened the door to our Miata, I stopped and stared. I wasn't mad. I was disappointed.

Maybe I was upset because it reminded me of that Nardi wheel in the first Miata I drove. I thought that was one of the coolest "car things" I've seen. It's right up there with the leather driving gloves that came with the Mercury Capri my Dad bought when I was a little kid. (My brother subsequently destroyed the Capri and the garage door by dropping the car into reverse before he actually opened the door. Hilarity ensued.)

I guess I'm in the minority in regards to the Nardi. I'll miss that knob. I felt it was one of the cool details that made the M Edition special.

What you see above is a peek into Oscar Jackson's brain. That little restrictor pill is an example of the persnickety-ness built into the Kraftwerks supercharger kit in Project Miata, our longterm 1997 Mazda Miata.

I'll spare you an excruciating step by step installation process since Kraftwerks includes instructions far more comprehensive than I could (or would) write here. Instead, here are a few details that illustrate the gray matter behind the Kraftwerks kit.

That pill lives in the vacuum line that links the supercharger's bypass valve to the intake manifold — manifold vacuum is what provides the muscle to actuate the valve. As it turns out, sans restrictor, the muscle was too strong and the bypass valves in Kraftwerks' beta test cars would open and close abruptly when feathering the throttle. This in turn made the boost hit and release too quickly, upsetting the cars' driveability. Picture Oscar frowning.

Making the bypass valve actuator breathe through the restrictor's tiny little pee-hole forces it to move more gradually, eliminating the abruptness. An elegant solution. That's Oscar smiling.

A few more examples — this cylinder with the extrusions is the reservoir for the Rotrex's magic oil. It's a thing of a certain size, and the best location for it was already taken by the factory horn. The kit includes a lower-profile replacement (also shown here) for the factory hood latch bracket and relocates the horn to the other side of the latch. The lo-pro bracket also serves as the mounting point for the reservoir.

Same goes for the power steering reservoir, which gets a new mounting bracket — supplied in the kit — to make way for the intake plumbing. Also, the stock washer bottle of ABS-equipped cars is in the way of the intercooler hose, so Kraftwerks includes a new (factory NB) washer bottle and bracket that mounts near the brake master cylinder.

Suffice it to say that every bolt, clamp, ziptie, hose and bracket in the kit has been similarly scrutizined, and the company tells us they've accounted for every possible Miata build variation of a/c, power steering and ABS. It doesn't get any more 'bolt-on' than this.

It's Traction Fluid

Oh, and that magic juice is a key part of how the Rotrex works. It's a shear-thickening oil (like the stuff in a viscous coupling AWD system) which is critical for the planetary traction drive to actually transmit torque. Don't go putting, say, gear oil in there else the supercharger will do a fine impression of a torque converter with an infinitely high stall speed.

This means that unlike a turbo, the Rotrex requires its own independent lubrication loop. The oil is fed via a pump in the supercharger's case, and then evacuated by a second integrated pump. In turn the internal planetry drive receives a fine mist of oil rather than being drowned in liquid. The oiling system uses a dedicated filter and cooler (shown adjacent to the reservoir above) and said oil & filter can go 50,000 miles before needing to be changed.

Engine Control

The kit includes a clip-in injector harness, a higher-flowing fuel pump and a black box that extends the pulsewidth of the stock injectors. An integral MAP sensor lets the box know when and how much to modify pulsewidth while an oxygen sensor clamp keeps the stock ecu happy at all times.

This approach, combined with an auxiliary 8:1 fuel pressure regulator, is said to provide enough additional fuel to keep things rich and cool at full boost and revs. There is no ignition timing control in the black box, the thinking being that the boost is mild enough that the stock ignition curve allows ping-free motoring on premium fuel.

While tinkerers will prefer a unit that is user-adjustable, nonadjustable devices make CARB happy since the car runs exactly as stock during start-up, idle, cruise and many part-throttle conditions. It's a kit intended as a straightfoward and no-fuss way to get a modest but meaningful power bump.

How much of a bump, exactly? Will let you know shortly.

OK, I know you guys really want to hear more about the new supercharger in our 1997 Mazda MX-5 Miata. But Project Miata editor JayKav will be doing another update on it soon so stay tuned.

In the meantime, the other day, I had to take my visiting sister to the airport. But before I picked her up, I asked her how big her luggage was since I was driving our 1997 Mazda MX-5 Miata. "I just have a carry-on," was the reply. But when I arrived and saw her fat carry-on, I was a little concerned.

See, we have a spare tire in our already tiny trunk. Would there be enough room back there for even this standard-size carry-on? As I stood there pondering this, my sister said, "If it can fit in the overhead compartment it can fit in there." She had a point so I gave it a shot.

Sure enough if we shoved it into the side of the trunk top first, it slots in nicely. We just had to lift the bottom up and slot it out again when we wanted to take it out.

On a side note, after some heavy rains, the trunk showed that it has a leak. There wasn't standing water a la Cruze but if you poked the lining, water seeped through. Suffice it to say it drenched a backpack I put in there. When I told Project Miata editor JayKav, he said this is nothing a hardtop can't fix. Nooooo!

I got a chance to take out our Miata last night, but it has an aftermarket radio with a detachable face, and I couldn't find the darn thing. And so I drove home without tunes. But between the road and wind noise and the whine of the supercharger, this car makes enough sounds to keep your ears occupied. It was an unadulterated, mechanical sound, reminiscent of our Corvette Z06 — only much less throaty.

As I listened to the music of the road, I had to wonder how effective those faceless units really are at deterring thieves. My car stereo was stolen a few years ago — while the detachable face was resting safely in my house. I have no idea how the thieves got the stereo to work without it.

Yeah, the trunk gets damp, but that just proves that Project Miata, our longterm 1997 Mazda MX-5 Miata, is being driven despite the deluge we've been experiencing here in LA for the past week or so.

First, that leak. Then the driving with the supercharger.

My esteemed colleague Ms Pardilla mentioned earlier that the Miata thinks it's a Cruze. For those readers that for some reason don't read every word we write here at the gilded IL halls, the trunk of the Cruze leaked early on and apparently passed this bad habit down to our lowly Miata.

Some experimentation with a pot (that's A pot, you fiends) of water showed that the leak is centered right above where the spare tire lives (see lead pic). Pouring water down the softtop triggers the drip, so either the softtop's rain rail is cracked or misinstalled, or the car's drain channels are plugged.

Regardless, the top's got to come out to resolve it. If you've read my previous diatribes regarding Miata softtops, you know I'm no fan, and this is yet another reason softtops suck. This will be my excuse for perma-installing the hardtop when I'm finally in town long enough to remove the soft and install the hard.

Much more exciting than that, though, is the Kraftwerks supercharger kit. It's given the Miata's rather trucky 1.8-liter BP engine a more urgent character and a much-needed heaping of beans. It's definitely not a bottom-end grunter like you'd expect from a Roots blower, though there is a bit more low-end sauce than before.

Nor is it some high-strung, peaky thing. Lay into the throttle and the shove builds linearly as the revs pile on. Unlike a stock Miata, acceleration is now more than adequate for passing maneuvers, and we've taken a few people by surprise on LA's ever-present onramp drag races.

Finally, thanks to the supercharger, the engine is not totally overshadowed by the capabilities of the chassis around it. A degree of balance has been brought to Project Miata's equation. Speaking of balance, the linear response from the go pedal makes the car a cinch to balance using the throttle, provided you've got the revs dialed up. You can meter out or reign in the power in a predictable fashion. It's now a sharper tool for driving.

It's actually worth revving it to redline now, the way a sports car should be.

I took the opportunity recently to flush out Project Miata's fluids of unknown provenance and install a set of Stoptech braided stainless brake lines. For the geeky deets, hit the jump.

Gear Oil Gotchas

Be careful when choosing gear oil. It is categorized into different performance classes, known as API Categories. Mazda specifies API GL-4 for the Miata transmission. But, hey, check out this API GL-5 stuff. Bigger is better, so GL-5 must be one number better than GL-4, right? Wrong.

GL-5 oils have much higher concentrations of extreme pressure additives that make them suitable for use with the low speeds and high torque levels experienced by the ring and pinion in your differential. This sounds like the hot setup for the manual gearbox behind a highly modified engine, except that GL-5 oils lack the friction modifiers needed for the gearbox's synchros to operate correctly. Simply put, using a GL-5 oil in the Miata's gearbox will eventually turn the synchros into Captain Crunch.

Some modern manual gearboxes however can live happily with GL-5. Your owner's manual will tell you.

Redline MT-90 is GL-4 oil. It's synthetic, so it ought to tolerate higher temperatures better than non-synth stuff. Same goes for the Redline GL-5 gear oil I spurted into the diff. Both are 75W90 viscosity, same as the OEM specifications. The conventional wisdom that 'thicker is better' for performance cars really doesn't hold much weight (har har) with respect to modern oil formulations.

Stoptech Braided Stainless Brake Lines

It's true that braided stainless steel brake lines expand much less than the stock rubber ones and that this translates into better brake pedal feel. However, replacing the brake lines in Project Miata is as much about safety as it is performance. Brake lines do fail, and the older they are the more prone they are to degradation.

The car has 127k miles, and the original brake lines have lost much of their original compliance. The last thing I want is for some crusty old stock rubber brake line to spring a leak in the braking zone of turn two at Laguna Seca. Enter Stoptech stainless steel brake lines.

Stoptech's brake lines are a PTFE inner sleeve surrounded by a snug-fitting stainless steel braided sheath that resists the expansion caused high brake line pressures. Atop the braiding is a clear plastic coating that prevents the stainless braid from chewing through anything it comes in contact with (if the line rubs anything on the suspension then they're been installed incorrectly anyway).

At the ends of each line is a hefty strain relief and plated steel fittings and new copper crush washers for the banjo fittings. All robust-looking stuff. The Stoptech lines are DOT-compliant, too, each line being subjected to a 4500 psi leak test before being packaged up. The only thing that's missing from the Stoptech lines is an orientation tab on the fitting at the caliper end (the stock ones have this), so you just have to take some care to ensure you've aligned the fitting properly before and after torquing the banjo bolt. No big deal at all.

During threshold braking, Miata brakes have a tendency to be difficult unlock once you've locked one up (exacerbated by too much front brake bias, particularly in the early cars sans ABS). This is due to compliance elsewhere in the system — flexy calipers are the likely culprit. The stainless lines won't cure it, but they will reduce a bit of that hysteresis in addition to the peace of mind they provide.

At last, the Miata has been couped.

Gone is the tan, floppy vinyl roof and in its place is now the second-hand, black hard top salvaged from round one of Project Miata. What's better? What's worser? Click below to find out.

So what's better? Well, for one thing, visibility is now really good. Check out the view from the driver's seat below.

Where before there was nothing but buffeting vinyl, there is now glass; nearly eliminating any blind spot. Another obvious difference is how much quieter the cabin is now that it's got a proper roof covering it up. It's still a noisy ride on the highway, remember, there isn't much in the way of sound deadening in this car, but it's much less boomy than it was before. Another benefit is the increased headroom, thanks to the lack of the convertible top's metal trellis which brings up yet another benefit. There are now no longer exposed steel rods fractions of an inch from your head just waiting to dent your noggin. Yay, benefits!

So what's worser? Well, not that the color combination of bass boat green and tan really looked all that great in the first place (someone figured that's what old British convertibles actually looked like) but now with the black top, this Miata is just plain weird looking. It's a total mutt.

I don't know, it might grow on me. Maybe.

Behold a relic of the 20th century. It has no panic button. It does not cost $150 to replace. It has an actual shank that slips into the ignition and starts the car.

The key could stand for a lot of things in the Miata, which felt like old-school driving to me, as someone accustomed to 21st century automotive appointments. As my colleague Ron Montoya pointed out recently, the Miata's radio is out of commission at the moment, so what I heard was the engine and road (and a weird chattering at higher speeds, like an angry chipmunk on helium. Didn't seem like a serious problem). It does have a hardtop now, which seems to upset some of you, but even with that and closed windows, I could smell eucalyptus trees on my drive home. Finally, I felt the road. Did I ever.

I was very conscious of how low I was, flitting along like a minnow in streams of motor whales. That took some getting used to. ("I'm lower than that Smart. I'm lower than that 911. I'm lower than that Mini?" Yes. I was.) I flipped up the lights and drove that way through late-afternoon traffic. It made me feel more visible. I'm not sure I really was.

But for all that, once I hit about 65, the car seemed to come into its own. At whatever speed, it's extremely responsive, and in reading up on some Miata history, I found that Mazda was striving for Jinba Ittai ("rider and horse as one") handling. It's a fitting description. Side and rear visibility are excellent. I could pick on the heater, which forced me to choose this morning between warm hands and warm feet. But that's a mere cavil.

I wanted a Miata, back in the day. My instincts then were good ones.

I was spoiled by our third-generation long-term 2006 Miata, whose neatly packaged trunk would accept rollaboard bags. I know Caroline fit one in here, but not so for my heavyweight 24-incher. Ah, nevermind. With my passenger loaded, I drove off and my thoughts immediately turned to Project Miata's supercharger installation.

What tractable power the blown 1.8-liter delivers at low rpm. The car accelerates smoothly off idle and gets stronger and more exciting as rpm build — and it all happens without a hitch. No random stalling, no stumbling, no burping, no snorting, no strange odors. If I didn't know better, I'd think this '97 Miata came this way from the factory.

And honestly, I wouldn't mind if that was the case. If all Miatas were this quick and this easy to drive, Mazda would probably sell a few more.

I think if this were one of my personal cars, I'd keep the folding soft top. I like convertibles, always have. Maybe if I put the Miata on track, I'd pop the hardtop on. As it is, the top of the side windows are about an inch above my eyes. In most cases, I have to duck my head down slightly to get a good view out the side. I have to duck even further down to see traffic signals if I'm first in line. I'd rather go top down, where I the only impediment is the windshield frame.

Where the performance upgrades are concerned, hats off to the talented Mr. Kavanagh. The supercharger produces smooth and linear power. There's none of the harshness that I've experienced in lesser project cars. Sure, it's a little loud, but I like the hiss when you let off the gas. I wasn't all that impressed by its straightline acceleration, to be honest, but in the turns the Miata feels like it has the perfect amount of power.

The new brake lines are a huge improvement, too. No more soggy pedal that squishes sloppily when you need to get on the binders. If this were a track car, though, I'd prefer a firmer pedal — especially if there's no ABS.

Put some sticky tires on this thing and it'll be a riot to drive at the Streets of Willow. I think it'd be interesting to see how it stacks up against my darling Elise.

The latest mod to project Miata is something I could really wrap my hands around. Jay Kav installed a new Momo steering wheel and it's perfect for this car. First off, it's a proper sports car style — meaning it's a three spoker. The previous wheel (like most of the '90s era) looked like a vinyl-upholstered throw pillow with a ring around it. Mind you, the Miata's wasn't quite as bad as this, but still. Since then, car makers have been able to package the air bag in a smaller hub, making for much better aesthetics.

But back to the Momo. Yes, we sacrificed the air bag. But not only does the Momo look just right, it feels the same way. The leather-wrapped rim's medium thickness should be about right for most folks — not too thin and not Python-like, as with some newer BMW M sport wheels. Whether cruising with my thumbs resting on the reliefs or quickly shuffle steering, it provided a great tactile connection between Miata and me.

Stay tuned for an upcoming post by Jay which will provide details on the install.

You've seen Project Miata's baseline output numbers. To recap, there were two sets of baseline dyno data since the car's cam timing was off when we bought it. Blame the primates. Once the cams were set to stock and the car's health confirmed, we forged ahead with the installation of the Kraftwerks supercharger kit in confidence.

This situation precluded measuring the car's real, actual, proper baseline output on our usual dyno — MD Automotive's Dynojet. We've built a large library of dyno runs for dozens of cars on this dyno, and I try to be scrupulous about capturing each change here so that we can compare to other cars we've run. I had the foresight to run a baseline dyno test on the Dynojet, but that was when the cam timing was unknowingly jacked up.

In this quandary I saw opportunity. We can turn this frown upside down and quantify the differences between three dynos. Yes, three — along with Kraftwerks' Superflow dyno and MD Automotive's Dynojet, I ran the now-supercharged car on Church Automotive Testing's Dynapack dyno.

If all you want to know is how much sauce the Kraftwerks supercharger kit added over stock, look no further than above. Peak power rises by 60 horsepower, while peak torque ratchets up by 37 lb-ft over the baseline post-cam adjustment run.

Hey, the math is easy on this one — that's a 60% increase in peak power. As you can see from the torque curve, the kit's effect at high revs is more pronounced than in the lower reaches of the rev range, but there's no denying the across-the-board increase.

With the supercharger, our Miata's 1.8-liter four drives in a nicely linear fashion — the power rises in lockstep with your right foot's position, and this effect makes it feel simply like a larger, more rev-happy version of itself. It's worth revving now. I dig that. It's not hopelessly slow anymore, either, and I dig that, too.

So what'd it do on our standard dyno, MD Automotive's Dynojet? See here. Just a day after running the supercharger's numbers at Kraftwerks, with the same fuel in the tank and pressure in the tires, we have about as apples-to-apples a comparison as we can get.

What stands out here is that the Dynojet says peak power is now 173 horsepower and peak torque is 141 lb-ft.

Green lines are supercharged. The purple traces are the pre-cam adjustment baseline numbers, of course.

Moving right along to Church's Dynapack (orange traces to your right), the measured output of the supercharged setup is higher still — 187 horsepower and 157 lb-ft. Again, same fuel in the tank, and run within hours of hitting MD's Dynojet.

What's going on here is painfully obvious but lost on many performance enthusiasts — different dynos are different. The Dynapack, for example, attaches directly to a car's hubs, thereby eliminating any tire slip losses. It's a loading-type dyno like the Superflow, the ramp rates of which can be set differently.

The Dynojet is simply a large drum of known mass with no provision for holding load points or modifying ramp rates. Great for consistency, but tuning part-throttle and steady state stuff is difficult unless you spring for one of Dynojet's newfangled dynos. MD's Dynojet 248 is the OG inertial-only one.

Here's an overlay of the our supercharged Miata's torque (easier to visualize than power) as measured by the three dynos. In the case of the Dynapack, perhaps there's more going on than just the tire slip losses, as those would increase with engine speed. Here the difference is not rpm-dependent. Hmm.

Weather is another factor to consider, particularly in regions that aren't southern CA where the girls are hot and the weather consistent. We applied SAE weather correction to all runs here as per SAE's procedure and saw less than a couple percent correction applied among all three dynos. It is worth noting that the air density in the supercharged car's intake manifold isn't necessarily fully represented using ambient conditions as the basis of correction. But weather correction is at least a step in the right direction, particularly for normally aspirated and supercharged (but not turbocharged) cars.

With that said, we tested on all three dynos within 18 hours, and the weather conditions in southern CA are as stable year-round as one could ask for. Still, we observed some variation in ambient pressure at each shop. There might be some variation from sensor to sensor, and the way to address this is to bring a weather station to each shop, something I might undertake if there is interest in more of this dyno-a-thon-ing (plus I'd add a Mustang dyno to the mix, use an n/a car, and quantify 2WD vs 4WD).

But your average enthusiast doesn't have this luxury. The numbers he gets are what he gets. What's important are the gains observed on a given dyno rather than the absolute numbers.

And in our case, observing 60 additional horsepower in Project Miata is a step in the right direction.

Perhaps you're perplexed as to why one — namely, us — would want to replace the steering wheel in a car like Project Miata, our longterm 1997 Mazda Miata project car.

Well, I'll tell you why.

Mainly, the size and position of the stock Miata's wheel sucks. The non-telescoping, non-tilting, smashed-against-the-dash tiller forces you to move the seat forward into a somewhat more knees-bent driving position than you'd find in other cars. It's got a large-ish overall diameter (and has a pencil-thin rim) to boot.

As a result, tall guys tend to bang their right knee against the steering wheel and/or have difficulty executing heel-toe downshifts.

It appears the driving position was arranged around the proportions of a Japanese guy instead of an American dude (don't laugh, it happens; see first-gen Honda Fit). Or it could be that the US airbag requirement drove the engineers to put some real estate between the wheel and the driver's torso to minimize collateral damage during an airbag deployment. Note that Canada-spec (non-airbag) Miata steering columns of this era located the wheel closer to the driver.

Whatever the reason, the last straw in our case was that the leather on our stock 128k-mile wheel was delaminating and pockmarked like Edward James Olmos' face, and the two probably felt similar. It had to go. Yes, the airbag goes with it, and I'm okay with that, as airbags of this era were designed for unbelted occupants and so deployed with considerably more force than today's bags. I'll stay belted, remove the bomb and save myself the broken arm, thanks. But with what to replace the stock wheel?

First thing is to settle on the desired overall diameter. The stock wheel is 365 mm. The selection of 350 mm aftermarket wheels is huge. This size will also provide more knee clearance and slightly quicker steering with a touch more effort. Fine by me.

Then you need to decide how much closer you want the new steering wheel to you. In this case, the target was an inch or so, as this is enough to make a noticeable difference (more than you might think) while still leaving the stalks within easy reach. Since the stock wheel is about 120 mm in overall height (from rim face to the back of the splines), the target dimension (this is known as offset) for the new wheel is roughly 145 mm. The installation of an aftermarket wheel always includes an adapter of some length which must be added to the wheel's offset. Learning the adapter's length prior to purchase is easier said than done.

As for the rim, wood is just out. No silly flat-bottom nonsense, either. Suede provides great grip when used with racing gloves, but can be slippy with bare hands (until your palms sweat), plus suede dirties very quickly and gets crusty due to UV exposure.

Leather wrap and round rim it is. Easy decision.

It turns out the Momo Mod 08 ($180 online) fits the bill, as the offset is 90 mm while the Momo adapter is 55mm in length, giving us 145 mm overall stack height. Clearly, the Mod 08 is a deep dish wheel, so it looks bitchin, too. I wanted to avoid adding spacers if possible, since more stuff stacked atop the adapter is, well, more stuff. Less is better.

Ah, the Momo adapter. This piece of metal is simultaneously indispensible and infuriating. It turns out Momo didn't develop an adapter specifically for the Miata, instead simply reusing one they developed for another Mazda. Go figure. Best-selling sports car in the world, and Momo couldn't be bothered with developing a plug and play adapter. But I digress.

The Momo adapter makes the installation a pain, but the fact that it is engineered to collapse in an impact means you really, really want it. There are other aftermarket adapters that allow for easy installation, but none of them appear to have been designed to be crashworthy.

Looky here. The Momo adapter has a face and struts made of steel, around which an aluminum base has been cast. Each strut has the built-in mechanical fuse shown here which makes for controlled deformation in an impact.

When you attempt to actually install the Momo adapter onto the steering shaft, you quickly realize that the adapter runs right into the clockspring connector. This doohickey houses a long ribbon of wire wound in the shape of a loose circle, and its function is simply to allow the wiring for the horn and airbag to make the leap from the steering wheel, which moves, to the dash, which doesn't. Horns are important, even in race cars, so the clockspring (below left) needs to stay.

In short, you need to clip off the connector for the horn and airbag (don't bother de-pinning it; there's not enough space in the adapter to package the stock connector shell), modify both the clockspring connector (center) and the adapter, and when you've hacked them both away to the extremes of your comfort level, they'll just barely coexist peacefully. It takes a die grinder, a Dremel and many cuts-and-tries to get it right. Above right is the adapter midway through hacking it up.

The rest of the installation is straightforward stuff — wire up the horn, click in the airbag resistor purchased from a friendly member of clubroadster.net, tuck the wires inside the adapter and bolt on the wheel.

With all that said, the Momo wheel is truly a nice bit of kit. There's no flex to speak of and the leather looks and feels great. Its thicker rim just feels more substantial, and the wheel placement is much more agreeable and, yes, there's now more knee room. The new wheel makes a surprising difference. I'm a fan.

As a bonus, the horn button is now in the location to which your brain automatically guides your palm when that douchebag in the bro-dozer changes lanes on top of you.

After hopping into the Miata early the other morning, I noticed the rear window obscured by fog. I also noticed the lines in the hardtop's glass indicating the presence of a defroster/defogger. Knowing our car didn't originally come with this optional hardtop, I wasn't sure if this feature was operational. I checked the dash (and the owner's manual to be sure) and nope — where the rear defroster switch would be there is a blank. Actually, as our Miata was fitted with an aftermarket anti-theft system, there is a red LED there.

In any event, I kicked it old school and just wiped the sucker off in about 10 seconds. Back east on the same day, it would've been a different story...

Just had my first drive in the now-supercharged Miata, and color me impressed. The extra power makes the little Miata far more exciting to drive, and it gives us a much better chance against unsuspecting Honda S2000s in stoplight races.

What's more, the 60 extra ponies come with zero reduction in drivability; just plenty of smooth, linear power from throttle tip-in to redline. Well done, Kraftwerks.

One thing that is noticeable is a constant (but mild) whooshing of air from the bypass valve whenever you're off the throttle or at steady-state light throttle on the highway. It's only slightly annoying (honestly), and quite often it's drowned out by the thrum of the tires anyway. The sound goes away when you get on the throttle, replaced by the music of a now-robust four-cylinder that loves to rev, with a small whoosh from the bypass valve with each shift.

The supercharged Miata doesn't have the kind of sauce to make lurid powerslides as simple as just planting your right foot midcorner, but it definitely ups the fun factor.

Count me in the camp that's glad JayKav added the hardtop. Even though the color doesn't match, it still cleans up the Miata's lines and makes it look a little tougher (if that's possible for a Miata). The more airy rear window is a bonus for rearward vision.

The new Momo steering wheel is also a nice addition. Personally I would've chosen something with a thicker rim, but hey, Jay's doing the wrenching so he gets to make these decisions. Never once did I give a thought to the lack of an airbag, though. Call me a crazy risk-taker.

Not sure if you're aware of this, but there's a whole industry devoted to just making your car clean.

There are washes and treatments, lotions and potions — all designed to keep your car looking good. You don't even have to do it yourself, as there are these big places where people will do it for you. They are called "car washes."

It kind of makes you wonder how our poor old Miata ever got to looking so bad. How many years did it suffer, parked in the back of some apartment without even a carport to keep off the sun? And yet it's never too late for cleanliness. Even in its worn and sun-bleached state, the Mazda still seems to sparkle once it's been to the car wash.

It's not that a little cleaning makes a car look like new. (This Miata will never look new again, no matter how hard you rub on it.) But when a car is clean, it seems like it's been prepared just for you. The connection is a little stronger in some special way. Even when you're just at the car wash and they tell you that your car is ready, it just seems like your relationship with the car is a little more personal.

It's always tempting to dismiss all that car wash stuff, those weird concoctions of chemicals that seem like patent medicine. Totally not worth the money. And yet if you keep thinking you're too smart to squander your money on such frivolous stuff, pretty soon your car starts looking as bad as this poor old Miata. So instead of saving money, you've actually squandered the intrinsic value of your car.

So go to a car wash, maybe go off your usual menu and get something special, maybe a clay bar treatment and some good wax.

Well, I've been off the track and spinning in the grass before myself, windlassing the steering wheel left and right with the windshield wipers going (as inevitably happens as your desperate hands brush the control stalk) while desperately trying to get the car straightened out. That's when you find yourself kind of wondering which way the front tires are actually pointed.

Which is why racers — especially rally guys and off-road racers — like to have a stripe on the rim of the steering wheel. Engineering Editor Jay Kavanagh knows this, and in fact he races a Miata himself in the 24 Hours of LeMons. So he has a good reason for picking out a Momo steering wheel for this car that has the racer's stripe on the rim.

And yet as short and responsive as the MX-5 is, most steering corrections are a matter of just a few inches of input. It's not the kind of car that really gets very far out of shape in a corner.

So when I saw the racer's stripe on this steering wheel, it made me wonder just how bad things would have to be in a Miata that you'd be wondering which way the front tires were pointing. Probably things would have to be really, really bad.

Of course, maybe Kavanagh just drives the Mazda a lot harder than I do. (Note to self: Don't ride with Kavanagh, especially in the Miata.)

This will probably get me in trouble with Project Miata editor JayKav but it has to be said. I saw this Miata the other day on the way to the beach. Now, if this was a hard top the driver wouldn't have been able to take his boogie board (?) to the beach and his Saturday would have sucked.

Some of you debated whether that was oxidized paint or morning dew on the trunk lid of our 1997 Mazda MX-5 Miata in this post's photo, so here's a closer look. Yup, definitely not dew.

Damn, this 1997 Mazda MX-5 Miata is so much fun to drive. The above video (warning: turn sound off) of Project Miata editor JayKav's 24 Hours of Lemons racecar in last year's Thunderhill race is the closest way I can convey what it feels like to drive this long-termer. (Yes, there is a turbocharged Miata underneath that Enterprise disk.)

Our Miata's quickness and nimbleness make it really easy to just get around all the slow pokes on the city streets. And I credit its ability to jump in front of other motorists without offending them due to its low-to-the-groundness and diminutive stature. Now, if I pulled that same maneuver in a larger car, like a Honda Civic, I know for a fact it would incite road rage.

As it is, the Miata flies below most everyone's eyeline and disappears before it even occurs to the other motorist that someone (me) got around them. But although it's a blast to drive in the daytime because of that, I find it kinda dicey at night for the same reason. This is compounded by the fact that the huuuge headlights really aren't all that great.

Wow. The Mazda Miata roadster passed the 900,000-build milestone this week. Read more in this article by Autoweek.

I wonder what number our Miata is?

Congratulations, Mazda. Zoom Zoom.

Wow. Those small pulleys generate tons of fun. I'm not sure you could get any better response to throttle input unless you were riding atop the engine, pulling on the butterfly. It wasn't until driving back to the office this morning that I put two and two together. Several years ago, Oscar Jackson said he was working on a new project with Rotrex superchargers. I remember that his original company, Jackson Racing, not only excelled at Honda supercharging, but also in force-feeding Miatas. Then the light went on, and I was happy to hear Editor JayKav confirm my hunch.

Oscar was one of the first heavy technical minds I met in the Honda world, and always gracious with his time. He indulged our magazine staff's notions of building a Super GT-spec NSX for the street. A raised glass to him and JayKav for this ridiculously fun car in its present state.

Even after a loud and bumpy 100-mile commute, no muscloskeletal complaints. It's stiff, but not stone.

Momo wheel and shift stalk feel perfect. The Miata is like a perfect bookend to the Z06; they appeal to different senses, but both get to the matter: thrilling acceleration and satisfying speed.

But Project Miata is loud. All that tire, road, and bypass valve noise sounds like an old faucet left to run wide open. There's a radio in there — a nice Sony and some good speakers — but it's a losing battle. It's more fun to listen to the blower whine, anyway.

That slight, rising whistle is the only thing I can figure attracted a pair of clownballs in separate Mazda3's to buzz by at different points in the commute, one in a 5-door, one in a sedan. Both were either just showing some oddball Mazda love or asserting some misplaced authority.

Then later, a Miata came up quick in the rearview mirror, hung on the bumper for a couple of seconds, then made a clean jerk to the left and eased up alongside. Don't think he was prepared for Project Miata to put three car lengths on him in seconds. Good laugh watching him scramble to catch up, then hammer off to whichever Kookville he came from.

Still not sure what inspired all the attention. To a nearby motorist, Project Miata looks like a quiet, docile two-seater. No aftermarket exhaust grumble. Maybe it's the stance? The hardtop? The molting trunklid? Come on, Jay - straightpipe and racing stripe next!

We got the Project Miata aligned yesterday. Although eventually we'll be stuffing bigger wheels and tires under the Miata's fenders, the '97 hadn't been aligned since Engineering Editor Jason Kavanagh swapped over the suspension bits from the '94. So it needed to be done.

Jeff, the tech over at Stokes Tire Pros, was cool and did his best to get the Miata to the camber, caster and toe specs requested by JayKav.

Now properly aligned and with increased negative camber at the front, the Miata should be more lively and willing to turn in. I'll wring it out a bit on some mountain roads this weekend to see how Project Miata performs when driven the way it was meant to be driven.

Okay, not quite perfection, but pretty damn close. If you aren't familiar with Palomar Mountain's South Grade, this 7-mile stretch of serpentine asphalt in southern California (comprised of largely tight, decreasing radius turns) rises to about 5,500 feet. On the weekends it's a sportbike playland.

But the Project Miata proved its combo of light weight, reasonable-enough supercharged power and phenomenal grip make for one sleeper of a sports car (doubly so because the tires never squeal, unless you hit a patch of painted line). You have to really work to get this car loose, and when you do (usually with a bit of power-on oversteer, but occasionally also under hard braking while entering a turn) it's so well balanced and forgiving that it's easy to catch.

It could definitely use a bit more torque to make those oversteer moments more accessible. But it's truly remarkable just how stuck this Miata is to the road simply via stiffer suspension, a lower ride height and sticky (albeit wimpily-sized, at 185/60R14) Dunlop Direzza Sport Z1 summer tires.

You'll never be wowed by the power from the supercharger up a hill like Palomar, that's for sure, but Project Miata isn't wheezy like a stock Miata. And the "whoosh" from the bypass valve with each upshift adds to the car's flavor.

The brakes held up remarkably well, especially considering how hard the Miata was being pushed on some of the downhill runs. The pedal always felt just a bit mushy, but it never got worse (other than a bit of squeaking) and there were never any "Oh crap!" moments heading into a turn because it felt like the car wasn't going to stop.

There's so much about this car that makes it a willing back-road partner, from the quick turn-in and communicative steering to the precise, short-throw shifter to the excellent pedal placement for heel-and-toeing.

And because this was a two-up weekend trip with the old ball and chain, that parcel shelf where the soft-top would sit was a real boon since we couldn't quite fit everything in the small trunk.

Things that don't work as well: Those crappy stock seats. Not only do you sit a bit high, but the seatback gets so narrow toward the top that there's basically zero lateral support for your upper back.

Beyond that, noticed a few squeaks that I hadn't previously heard, including one toward the back of the roof on the passenger side and on the dash on the driver's side; but they only made themselves apparent on coarse, bumpy roads. And, this is a 14-year-old multi-owner car with almost 130,000 miles on it.

The steering wheel has started making a squeak when you turn it from left of center back to the right beyond center.

Oh, and Project Miata's low ride height made the short drive up a dirt road to our weekend cabin a bit challenging.

But the overwhelming experience was a fantastic one, with lots of admiration for just how quickly the Miata could blast up and down Palomar; it's all about corner speed in this thing. And the car proved bulletproof, the gauges barely rising at all, even during the hardest running.

Here's something to think about: The grip this car will have once it gets bigger wheels and tires. Then JayKav will definitely need to add some more power for the drivetrain to keep up with the chassis.

Ok, let me break this picture down for you guys. As you can see, my right leg is pressed right up against the rim of the original steering wheel. It's like that for two reasons. The first being the diameter of the old wheel was a little big. The second reason is because the steering wheel did not telescope. While my legs were happier with the seat moved all the way back, with the seat in that position my arms were all but locked out when I would turn the wheel past fifteen degrees. In a car with an old-skool airbag, getting in an accident, even a minor one, with your arm crossed over the airbag would likely give you and ulna induced lobotomy. I'll pass.

Click on through to see what the new wheel hath wrought.

That's better. Because of the dish the new Momo wheel offers, I can move my seat back. That makes my legs happy, as well as my knees, which are no longer pressed against the bottom of the dashboard. There is also around a three-finger gap between the bottom of the wheel and my leg. Now I can finally pull off some heel-toe trickery.

Something that will take a little time to get used to is the distance of the new Wheel of Death to the turn signal stalk.

It's not an impossible distance, but the first couple of times I swiped for the stalk, I whiffed. Every time since, I've reached it without a problem.

I should also mention that as someone who runs an aftermarket wheel in my personal car, this Momo is a really nice piece. The leather wrap feels great and the overall construction of the wheel is top notch.

To piggyback on Photo Editor Kurt's praise for our 1997 Mazda MX-5 Miata's new Momo steering wheel, another great thing about it? The horn. No more unsatisfying horn honking with thumbs! Horn honking with purpose FTW!

Sports cars are the biggest culprits in requiring fancy driving booties in order to properly operate their pedals, but our Miata is different.

Not only could I stuff my size 12 (44 for our European readers) Doc Martens into the pedal box, but I had plenty of room to use the pedals without once accidentally hitting the wrong one. Try that in a Lotus. Actually, don't - you'll never get out of the parking lot.

And no, I don't own a pair of Pilotis. Sacrilege, I know.

It's funny to think that 15-inch wheels can be larger than what was on Project Miata, our longterm 1997 Mazda Miata, up to this point. Yet the 949Racing 6ULs are one inch larger in diameter and a full three inches wider.

Given a long weekend, no travel plans and the Miata in my keep I finally had some time. Time to have the fenders rolled to accept the 15-by-9 inch 6UL wheels and 225/45 Hankook Ventus RS-3 tires. That's quite a bit more sizable than the 14-by-6s and 185/60s the car wore previously. FYI the stock wheels on the 1997 M-Edition were 15-by-6.

You might remember these wheels from when they were on the white car. I think these wheels look even better when contrasted against the green paint of this car.

And yes, with this wheel swap complete we'll run handling numbers to go along with the acceleration testing of the Kraftwerks supercharger kit.

The other day I saw spinners (to see what I'm talking about here's a video of 20-inch spinners on a Blazer) on a lowered, purple Impala. Another time a rear spoiler that looked similar to this one on a Civic. It's because of customizations like these that I had previously disliked aftermarket enhancements. Aftermarket stuff seemed to just give leave to car owners to treat their rides like a MySpace page. Chaotic mess with no rhyme or reason.

But the Project 1997 Mazda MX-5 Miata opened my eyes to the fact that aftermarket could actually be used to improve a car's looks and performance (wuuut?), when you know what you're doing that is.

With the hardtop, Momo steering wheel, and 6UL wheels, to name a few, our little Miata stands out from all others in a good way. Subtle enhancements that make this a kick-ass sleeper.

Yes, that's just M, not M&Ms. Our Miata is an M Edition, essentially a loaded version of the car that came with leather seats, a unique color and special wheels. If we're talking strictly first generation here and I get to pick from the dizzying array of M Editions / Special Editions (as we point out in our comprehensive Miata history), I've got to go with the 1995 M edition. The '95 M came painted a rich shade called Merlot Mica, which was nicely accented by the BBS wheels and tan upholstery. Though I like the look of real wood trim, I prefer the tactility of leather for vehicle controls, so I'd replace the wood shift knob and parking brake handle. Oh yeah, I'd also put in a Kraftwerks supercharger kit.

Any Miata fans out there agree with my choice or have a different M Edition / Special Edition of the first-gen Miata they'd prefer?

Sometimes, things just don't go as planned. The goal was to run acceleration, braking and handling numbers on Project Miata, our 1997 Mazda Miata, now that it's been infused with a Kraftwerks supercharger kit and meaty 6UL shoes.

Two out of three ain't bad.

Project Miata struggled this time around with a very tired and very stock clutch during the runs down the drag strip. After a single acceleration run with the thing slipping, we decided to scrub any further acceleration testing. Thus, the acceleration performance it posted is not representative. Nevertheless, that single accel run is shared below as an FYI.

We have a new clutch on the way and will re-test once it's in.

Our testing of its handling, on the other hand, went quite well. Check out the grip and the slalom speed, as well as Chris' comments. Yowza!

To recap, we'd run numbers on the current FatCat Motorports suspension back when it was on the white car. We never had a chance to track-test this hardware in conjunction with the 949Racing 6UL wheels and Hankook R-S3 tires, though, until now.

Vehicle: 1997 Mazda MX-5 Miata

Odometer: 129,627

Date: 3/1/11

Driver: Chris Walton

Specifications:

Drive Type: Rear-wheel drive

Transmission Type: Five-speed manual

Engine Type: Supercharged and intercooled inline-4

Displacement (cc/cu-in): 1,839/112

Redline (rpm): 7,200

Horsepower (hp @ rpm): 173 @ 6,900 (Dynojet chassis dyno)

Torque (lb-ft @ rpm): 141 @ 5,900 (Dynojet chassis dyno)

Brake Type (front): 10.0-inch one-piece ventilated cast-iron discs with single-piston sliding calipers

Brake Type (rear): 9.9-inch one-piece solid cast-iron discs with single-piston sliding calipers

Steering System: Hydraulic-assist rack-and-pinion power steering

Suspension Type (front): Double wishbones, FatCat Motorsports adjustable ride-height coilovers with coil springs and monotube dampers, Racing Beat hollow stabilizer bar and 949Racing endlinks

Suspension Type (rear): Double wishbones, FatCat Motorsports adjustable ride-height coilovers with coil springs and monotube dampers, 949Racing endlinks

Tire Size (front and rear): 225/45ZR15 87W

Tire Brand: Hankook

Tire Model: Ventus R-S3

Tire Type: Summer

Wheel Size: 15-by-9 inches front and rear 949Racing 6UL

Wheel Material (front/rear): Aluminum

As Tested Curb Weight (lb): 2,344

Test Results:

Acceleration

0 - 30 (sec): 2.8

0 - 45 (sec): 4.9

0 - 60 (sec): 7.7

0 - 60 with 1-ft Rollout (sec): 7.4

0 - 75 (sec): 10.7

1/4 Mile (sec @ mph): 15.6 @ 90.3

Braking

30 - 0 (ft): 27

60 - 0 (ft): 112

Handling

Slalom (mph): 71.8

Skid Pad Lateral Acceleration (g): 1.01

Comments

Acceleration: Clutch cannot handle both an aggressive launch AND wide-open throttle upshifts — obvious clutch slippage after each upshift. Still, it feels and sounds like the meanest Miata I've ever driven. Still love the shifter, but I would move the pedals slightly for easier heel-toe action.

Braking: Cold tires really confused the ABS system for the first stop. I thought it was just the tires and ABS not getting along so I did several non-ABS stops which proved very easy to find the threshold. After returning to ABS, found it worked best in the end.

Handling: Skidpad: Awesome balance, poise and compliance. This is how I would want a racecar set up. Steering is direct, precise, responsive and informative. The nearly-identical counter-clockwise and clockwise times speak to the amazing balance in theis setup. Didn't hit/feel bump stops or rub a tire.

Slalom: Took a few runs to get the tires to proper temp (first few I could tell the fronts were cold and not working). Then the balance I was expecting gave me confidence to attack. Like a Lotus, there's more roll than expected in transition, but also tons of grip and control (throttle-steer and steering-steer are both available and predictable). Joy!

Gary Coleman. Danny DeVito. Emanual Lewis. Wee Man.

Until yesterday, these were the only four people that could drive our Project Miata comfortably.

Personally I've been complaining about the Miata's seating position since I drove a pre-production Miata back in 1989. The seat angle is all wrong (kinda dumps you into the footwell) and the seat is just mounted too high. Combine that with a steering column with no tilt and I've always wondered why Mazda wanted you to sit on a Miata and not in a Miata.

Until yesterday I thought the only solution to this is an aftermarket seat. I was wrong. Dan Edmunds had another solution. "Pull the seat foam out," he said. "I did it to one of my Miata race cars about 20 years ago."

So I did.

Yesterday I pulled out the Miata's driver's seat and went for it. I peeled off its seat bottom upholstory as much as possible, stuck a hand in there and began tearing. What I found was very dense foam more than two inches thick. More platform than padding. I even had to use a steak knife to cut some of it out.

When I was done, nearly all of it lay on my driveway, but only sections from under the driver's butt. I left the side bolsters and the thigh support alone. The entire process took about two hours, and I did loose more than a little knuckle skin (blood everywhere), but the results were worth it.

I'd still like the seat to be about a half inch even lower, but now the top of the steering wheel isn't covering the top of the gauges, and you no longer feel like you're sitting on top of the car.

Perspective. That's something I neglected to include with Project Miata's most recent round of performance testing.

Like, for example, how it measures up in terms of outright grip.

Beyond the jump is a list of the top fifteen grippiest cars we've tested in the past four years. The results might surprise you.

Lat. Accel (g) Model

1.02 2010 Chevrolet Corvette ZR1

1.01 1997 Mazda MX-5 Miata; Project Miata

1.00 2011 Chevrolet Corvette Z06

0.99 2011 Porsche Boxster Spyder

0.99 2010 Porsche 911 GT3

0.99 2008 Mitsubishi Lancer Evolution X

0.99 2008 Porsche 911 GT2

0.97 2011 Audi R8 5.2 quattro Spyder

0.97 2011 Ford Shelby GT500

0.97 2010 Porsche 911 Turbo

0.96 2011 Porsche 911 Carrera S Convertible

0.96 2010 Chevrolet Corvette GS Coupe

0.96 2010 Porsche Panamera 4S

0.96 2009 Nissan GT-R Premium

0.96 2008 Lotus Elise SC

Note that the Porsche GT2 and GT3 use R-compound tires. Project Miata is on traditional street tires.

Also, we've had a few cars produce higher numbers at a facility other than our usual testing site — for example a ZR1 that produced 1.10 g and a GT-R Spec V that turned 1.11g. The list above shows new production cars all tested at the same site.

Now For Some Geeky Background On The Skid Pad

We use a 200-foot diameter skid pad. It's flat asphalt. It's not perfect — there are paint lines and probably some seam sealer here and there on the surface — but it is consistent. Surface temperatures, too, don't vary much. You won't see 30-degree temperature swings; Southern California is good like that.

Every car is run clockwise and then counter-clockwise, timed, and the results averaged. This always results in a less-impressive result than the instantaneous grip most tires are capable of briefly generating.

Often, the first run in each direction is the quickest. Subsequent orbits usually suffer since the heat liberated at the tire-road interface adversely affects their grip. It's rare to have to make more than two runs in each direction, and that's with alternating the direction each time to keep the tire temperatures in check.

The driver keeps the inside tire on the line all the way around the skid pad, and the "lap" time is measured. We use 103-foot radius for calculation purposes as that's roughly where the centerline of each car is located as it arcs around.

All cars, including Project Miata's most recent test, are tested with a full tank of fuel and all ancillary equipment in place unless specified otherwise. That includes a jack and spare tire or tire inflator kit, blowup doll or what have you.

Here's even more detail on how we test cars.

More Grip? For Reals?

Project Miata could be set to a lower ride height and likely generate even more grip. However, this would eat into its street livability — its current ride height of 4.75" front and 5.00" rear as measured at the pinch rails is about a half-inch higher than what you'd want on the track, and this, in turn, limits the amount of front camber that can dialed in. As it sits today Project Miata has -2.1 degrees front and -1.9 degrees rear camber.

Gaining additional negative camber while retaining the current ride height (which I like) would require offset control arm bushings. Perhaps a project for another day.

Also, a diet wouldn't hurt. For the car, I mean — I'm a wall of muscle. A 2,344-pound first generation Miata like this one is something of a plumper in the context of track-driven examples. Some targeted weight reduction is in order, I'd say, keeping in mind that it's a dual-purpose car. Meaning the a/c stays.

One of the worst things about this generation of Mazda Miata is the complete lack of steering wheel clearance. Let a pedal out and my knee hit the wheel. Turn the wheel and my hands hit my legs and the bottom of the wheel is ALWAYS rubbing up on my thigh in a very unwelcome way. It's unpleasant.

But not anymore. Oldham dug about six loaves of foam out of the seat this weekend and I'm happy to report that not only did this increase clearance, but it increased comfort. The seats in our M edition were ultra-firm and dead-flat. Now there's some squish (you could drive it for hours if not for the noise) and, being lower, the side bolsters actually work as bolsters.

I avoided driving the Miata because I hated the seat / wheel position so much. Not anymore. Now I just wish he'd scooped more foam out of the back, too. Next time.

Hmph. Well, I usually just leave it set to vents-and-feet anyway. So there.

The slider is jammed in the position you see above, so I crammed my torso into the driver's footwell to see what is amiss among Project Miata's various cables and rod linkages that regulate the direction of the breeze. Found nothing obvious in the time it took for my bum shoulder to really get pissed off, which is about thirty seconds. A problem for another day. Or another person.

In other, less-pedestrian news, I installed a Flyin Miata clutch and flywheel this week. And I'm likin' it. More on that later.

After Project Miata's tired stock clutch scuppered our plans to run acceleration testing, it steadily worsened. We needed a solution, so we tapped the fine folks at Flyin' Miata, the universe's single largest player dedicated to the Miata aftermarket.

Hit the jump.

A few days later, a box arrived containing what you see above — a Flyin' Miata Level 1 clutch and lightweight flywheel along with new pilot and throwout bearings, a clutch interlock override doohickey and an alignment tool.

"Level 1" might sound tame, but consider the specs: this clutch is rated to hold 318 lb-ft of torque (as measured at the flywheel). Project Miata in its current guise is twisting out 141 lb-ft at the wheels (Dynojet), so Level 1 gives us a wee bit of margin. Plus, it's purple.

The clutch disk itself is an organic friction material with a heavy copper loading that increases torque holding capacity. Here are some words of wisdom for the noobs in our midst: if you want to drive your car on the street, you want an organic clutch lining and not some ceramic puck-type nonsense. Non-organic clutch linings provide engagement that is like a lightswitch and/or very juddery and you will hate (and I mean HATE) your car. Track-only cars that don't need progressive engagement can get away with the more aggressive friction materials.

Barney the purple pressure plate is a unit with a relatively high clamping force. Clever detail work within means this clamping force is achieved without ridiculous pedal effort. By using more of the available pedal travel, the Flyin' Miata clutch can pile on more total clamping force with little change in effort. Flyin' Miata are smart like that.

A lighter flywheel is one of those decisions that seems like a no-brainer but is easy to overdo and then regret. Like the clutch lining question, prudence should rule here. On a race car, sure, make the flywheel as light as you can. We're building a true dual-purpose car, so it's got to be streetable. Go too light and it will be tough to modulate engine speed every time you leave a stoplight.

Really, talking about flywheel mass is incomplete. We should be talking about rotational inertia if we're to be totally accurate, as two flywheels of identical mass could have radically different inertia, depending on how that mass is distributed. This is because inertia changes with the square of the radius. But until flywheel manufacturers start publishing product data in units of lb-in^2, we're stuck with mass.