2002 Chevrolet Corvette: What's It Like to Live With?

Read the latest updates in our long-term road test of the 2002 Chevrolet Corvette Z06 as our editors live with this car for a year.

What do you want to know about?

- Introduction

- Pinging At Full Throttle

- DON'T Brace for Impact

- Burning Gas

- Back to the Dealership

- Easy Trunk Workaround

- Dealership Woes

- A DIY Special

- DIY Fix Part 1: Remove the Rat Poop

- DIY Fix Part 2: New Parts and Pizza

- DIY Fix Part 3: Puttin' Her Back Together

- Ditch The Heads Up Display

- No Yellow. No Moulding.

- Calling In The Pros

- A Real Lightweight

- Injector Flow Report

- Work In Progress

- Back In Action

- It Doesn't Leak

- The C5 Coupe's Weird Trunk

- Explosively Fast

- Oil and Notes

- Scrapes on Everything

- Love the Shifter. Hate the Shifter.

- Rain Dance

- 45,000 Miles and Still Rockin'

- Seating Position Is An Acquired Taste

- They don't make 'em like this anymore

- Makes You Dumber

- Great Pedals

- Taking Pictures Of Your Car

- Dyno Tested

- 'It Just Feels Beat Up'

- Can I Buy a Vowel?

- Feels Old But In a Good Way

- Alignment

- 'Service Steering Column Lock'

- The 150-mph Leather Recliner

- Is It Cool?

- HUD TMI

- Too Big for This City

- Minimizing the Big Butt Look

- Bottom of the Barrel?

- Monterey ALMS Weekend

- "Something Bit Me!"

- I'm hooked

- Want

- Brand-think

- That's A New One

- It Sounds Good, But No

- Stubborn Shifter

- Had a Bad Day

- Extended Drive

- Satisfying My Inner Caveman

- To Be, Or Not To Be

- Going The Distance

- Washing It Manually

- The Tire Dilemma

- Track Tested

- Yep, Even Oil Temp Is Here

- The Mystery of the Leaf Spring

- What Would You Get?

- My Id Is From Hazzard County

- 2002 Chevrolet Corvette Meets C4PO

- How's This Facelift Look?

- Abused

- 50k

- Think These Switches are Waterproof?

- Should We Change The Wheels?

- In Need of New Oil

- Oil is Changed

- The Ol' Hit and Run

- It's My Favorite

- The Downside of Lateral Bolstering

- So Great Minds Think Alike...

- Vote For Our C5 Z06s New Tires

- Shifter Options?

- Good Steering Wheel

- Our Vette Does Dogtown

- Two Thousand Words

- Racing Seat?

- Distant Thunder

- Ajar? What's Wrong With Open?

- A Great Car...for Tools

- The Best Option for a Used Corvette

- At Least It's Not a Viper

- Bogus Basin

- Better Than Coffee

- Time For a New Shifter

- Fast Or Rewarding, Pick One

- Engine Problems? What Engine Problems?

- Plastic Front Spoiler is Lookin' Beat

- Small Slice of Hell

- Pedaling to Work

- Do we have Clearance, Clarence?

- Not Just Another Car

- No Hail Marys Necessary

- Nice Ride, Man.

- The Legend Lives Indeed

- Grand Touring

- What Do You Think of Me?

- Fuel-Saver Smackdown

- Virtual Insanity

- Good Morning To You

- So That's Why the A/C Was On...

- Screwy Dipstick

- Nice Bulges

- My Other Corvette Is a Harley-Davidson

- Child Friendly

- VIN and RPO Codes

- Crash Boom Bang

- Midengine Corvette C5

- A Sincere Samaritan

- New Bridgestone Rubber

- Feel of the Wheel

- Scuffed

- Breaking in the New Rubber

- The 165-hp Stereotype

- Damaged

- The Laser-Equipped Pyramid Stereotype

- Ess El Pee

- Rocker Repair Complete

- Baby's Got Some New Shoes

- 150-mph Dump Truck

- What Should We Replace it With?

- Police Profiling

- On the Road to Buttonwillow Raceway

- Taking on a Storm

- Needs Oil

- 2002 Chevrolet Corvette at 24 Hours of Lemons

- Last Dance?

- Is That a Cupholder?

- Lapping The Streets of Willow

- Explain Climate Control

- Ditch the Seat, Keep the Seating Position

- Seat Wear Gettin' Worse

- Light Barf

- The Shark

- 55K And Still Going Strong

- In The Wet

- 405-HP Delivery

- Exhaust Video For Your Ears

- Trunk Latch Is Fixed

- Dry Cleaners Run

- How It Drives Versus a 2008 C6

- What Mods Would You Get?

- Tire Thoughts

- The Odd Couple

- Shiftin' For The Sake Of Blippin'

- Competitive Driving Mode

- Steady As She Goes

- Service Active Handling

- What Should the C7 Get?

- Freeway Vette Love

- The Future's Alright

- Pop-up Headlamps

- Daily Driver?

- Skip Shift

- Recaro Seat Installed

- Burnouts. Cause They're Cool.

- Puked in My Driveway

- Off to the ER

- Oops. Think it'll buff out?

- No Door Dings

- Coolant Leak Fixed

- It Did Buff Out. Mostly.

- Q&A

- Hand Wash Only

- Answers, Part One

- Answers, Part Two - As Well As Me Being Stoned to Death

- Who Did You Buy the Car for, Dude?

- Service Vehicle Soon Warning Light

- Our Favorite Caption

- Diagnostic Mode

- Legends of Riverside

- Service This

- Active Handling Service

- How I Roll

- What Am I Waiting For?

- Smog Check

- Beastly in Traffic?

- Enjoyable Even at 3/10ths

- Nice Set of Wheels

- Corvette Summer

- Oh My, This is Embarrassing

- What's the Right Number?

- And that Number is...

- Brakes Sound Like This

- Video Classified Ad

- What Should We Get Next?

- So Who's Gonna Buy It?

- New Owner's Dream Car

- Wrap-Up

Introduction

"What You Get For...," a popular column in The New York Times, examines the real estate market based on a set budget. You know, what you get in Queens for $1,000,000 vs. what you can get in Belchertown, Massachusetts, for the same price. Needless to say, the results are predictable.

But the car market isn't the housing market, and for us this is a very, very good thing.

You see, with $20,000 cash in hand, we could have ourselves a brand-new Honda Insight, a Chevy Colorado or two Nissan Versas. Or we could give the new car dealership the finger, take our pile of cash and wave it in front of this guy we ran into who happened to be selling a Corvette.

He took the pile of cash. We took delivery of our newest long-term road test vehicle, a 2002 Chevrolet Corvette Z06. It's a $20,000 car powered by a 405-horsepower 5.7-liter LS6 V8. It's gonna be a good year.

What We Bought

In 2001, the C5-generation Corvette got a shot in the arm and a fancy new Z06 badge. The Z06 package, available only as a fixed-roof coupe (FRC), upped the output from the base Vette to 385 hp from 350 hp, added bigger brakes, reduced the weight and jacked a high-performance suspension under the whole package. But the 35-hp improvement wasn't quite enough, so the following year the 2002 Z06 got a bigger shot in the arm by way of 20 more ponies, bringing the LS6 V8's final tally to 405 hp and 400 pound-feet of torque. This was, of course, delivered to the rear wheels by way of a six-speed manual transmission. That's the kind of used Z06 we wanted — the most powerful one. Unfortunately, that usually means the most expensive one.

It was easy to find 2001 Z06s with reasonable mileage at or below our $20,000 ceiling. It was more difficult to find a 2002 Z06 with reasonable mileage, no aftermarket mods and a careful owner for the same price. We drove a few, ran Carfax on all of them and finally settled on a weekend toy owned by a guy who just couldn't deal with two cars anymore. It's a rough economy out there, so when we said $20,000, he threw us the keys.

The car we found had only two options: self-dimming mirrors and a memory function for the seat and mirrors. When new, these options retailed for $270. When the car was new it carried a sticker price of $51,180.

Why We Bought It

There's a badge on the side of the car that says "405 Horsepower." So that about says it all. The only question is, why didn't we buy one of these years ago?

Times are tough; banks are failing. The government owns GM. The Italians own Chrysler (and so, partially, does the government). Having a second car just isn't as easy as it used to be. But for those with the means and desire to have a metric bucket of fun, there are deals to be had.

The 2002 Chevrolet Corvette Z06 is one of the coolest Corvettes ever. It might have fewer horsepower than a standard 2009 Corvette, but that's missing the point. In 2002 this car had over 400 horses and 400 lb-ft. It ran with Ferraris, Lamborghinis and Vipers costing three times as much.

But with used cars — especially four-wheel toys like this — come a litany of question marks. How well was this car maintained? How much mileage does it really have left? What do 40,000 miles do to a 405-hp fiberglass tub that had questionable (that is to say, bad) materials, fit and finish even when it was new?

We'll find out.

We said in "10 Best Used Cars for Less Than $19,999" that the Corvette was "the fastest car on this list. That it's dropped down to under $20K makes it an astonishing bargain. Compared to the regular C5 Corvette, the C5-generation Z06 was produced in tiny numbers — just over 28,000 were built between 2001 and 2004. And many Z06s were bought by older buyers who wanted the best, but actually didn't put many miles on them. And many have been pampered. So if you're looking for one, scour the obits and hit the estate sales!"

We followed our advice, looked long and hard and bought what we hope is the right car for a staggeringly good price. For the next 12 months and 20,000 more miles, follow along on our Long-Term Road Test blog. It'll be fun; we've already done burnouts.

Current Odometer: 41,906

Best Fuel Economy: 14.9 mpg

Worst Fuel Economy: 13.6 mpg

Average Fuel Economy: 14.2 mpg

Edmunds purchased this vehicle for the purposes of evaluation.

Z06: Knock, knock.

Me: Who's there?

Z06: Detonation.

Me: Oh, s#&@.

Two days after he picked up our longterm 2002 Corvette Z06, Senior Editor Ed Hellwig thought he heard engine knock at full throttle around 4000 rpm. I took it for a drive and confirmed that, sure enough, it was definitely detonation Ed was hearing.

The previous owner didn't pile on the miles. We figured maybe the fuel in the tank was old and had become octane-deficient. So we ran three tankfuls of fresh 91 octane through it. It made no difference — the Z06 still pinged like crazy.

We brought it to the dealer last week to have them check into it. They reflashed the ECU with an updated calibration and separated us from $98. Again, no difference.

At this point we thought maybe we were nuts. To be doubly sure that what we were hearing was in fact detonation and not something mechanical in nature, we added octane. Yesterday I mixed five gallons of 100 octane with the few remaining gallons of 91 still in the tank. The pinging vanished.

We'll bring it back it back to service once all the 100 octane fuel has been replaced with 91. Maybe this time they'll check the timing and verify that the knock sensor(s) haven't crapped out.

It's anyone's guess as to how long the engine has been running in this state. Though it runs strong according to the ol' butt dyno, a basic compression and leakdown test would be a good first step in determining whether prolonged detonation has caused any engine damage.

Car Boss, Mike Schmidt, knows I have the second-longest commute to the office so he asked if I'd be willing to burn some 100-octane fuel out of our new, old "Zed-Aught-Six." Sure, why not? The storms were retreating and I've not driven one of these notch-backs since, jeez, 2004-5 when the C6 came on line. A few things stood out on my mostly-dry drive home and a few more on my rain-soaked drive back.

The first thing that struck me was this passenger grab handle. Do you see anything dangerous about its design? I'm pretty certain it would absolutely be the worst place to grip in the case of a probable frontal impact. Best case scenario: two broken thumbs.

Next, I started to compile a shopping list for our Z06, starting with a new driver's seat and budget permitting, a matching passenger seat. Along with the rest of the automotive scrivenerdom, we've been complaining about Corvette seats for generations of Corvettes and now we have an opportunity to actually do something about it. We have one guy on our staff who has replaced his Corvette seat(s) with a set of Recaros. Have any of you replaced your Corvette seats? What did you get and why?

The next thing we must buy is a skip-shift eliminator. If you don't know what that is, then you haven't known the joys of driving late-model GM V8s in heavy traffic. They range in price from about ten bucks on eBay to $30 from a legit online retailer. Again, anything we should consider here? This seems a pretty easy fix and definitely a DIY project for Dan.

Finally, I realized the car should probably get a new set of front tires. (The rears have enough tread depth at this point.) Why, you ask? Well, the rain has returned in earnest and skiing in a Z06 is not my idea of fun. Of course, I stayed out of the puddle-prone No. 1 lane (closest to the center divider on the freeway), but even so, the car hydroplaned often enough and severely enough to keep me from so much as adjusting the volume on the stereo on my drive in this morning. Sipping coffee was both unnecessary and impossible.

I reached the nearby gas station tingling with adrenaline and about 1/8 of a tank of 100-octane fuel. I figured that was low enough to try a fresh tank of 91, so I filled it up. I've got one more commute in the car tonight/tomorrow morning, but with all this rain, it's highly unlikely I'll be able to go to W.O.T. to see if we've solved the detonation problem.

You've probably been wondering where our 2002 Chevrolet Corvette Z06 went for the past week. It's been on the road. As Jay mentioned, we decided to run 100 octane through the system to confirm the ping issue. Once that was official, we tried to burn off the good stuff.

We chose to put two tanks of 91 octane through the Z06 before handing it back to the dealer for further diagnosis. Our math figured two refills would dilute any remaining 100 octane mix and make doubly sure it was back to 91. The last thing we wanted was the dealer to test it with a higher octane fuel and give us the old, "problem cannot be recreated at this time" response.

Where do we stand now? We've transformed the last of our diluted mixture into ozone and we're back to full 91 octane. So we made an appointment with the dealer for Monday. We'll let you know how that goes.

We dropped our 2002 Chevrolet Corvette Z06 off at Cormier Chevrolet yesterday, as planned, to address the ping. No word yet. But we expect an update by the end of day today. When we know more, you will too.

We've been intentionally limiting how often and how hard we drive our longterm 2002 Corvette Z06 while we sort out its detonation issue, which is why posts related to the silver sports car have been few and far between.

Nevertheless, the handful of editors that have driven it have all muttered about its trunk refusing to pop up more than a millimeter or two when you press the trunk release. This makes the lid darned near impossible to open fully without prying it up with some kind of implement, which none of us dare attempt.

I found a way to make the decklid pop up all the way to a grab-able height without resorting to such cavemen techniques, though. The workaround involves a highly sophisticated fluid mechanics phenomenon that I demonstrate in the video above. Gotta make sure those windows are rolled all the way up for it to work.

By now you know the story behind our 2002 Chevrolet Corvette Z06 and its engine knock. We dropped it off at Cormier Chevrolet as a starting point, expecting the Corvette-centric dealership could mend our ailing LS6. We expected too much.

Office chatter on the day we picked up the Z06 went something like this:

"Is the Vette fixed? What did the dealer say?"

"The tech drove it while hooked up to his computer. He recreated the ping but even at the moment of detonation his equipment showed no signs of error. The knock sensor did not relay a fault. The tech elaborated. He said this ping was an issue he'd seen on numerous occasions and would consider it characterisitc of this engine. Some are cured by the ECU recalibration we had. Others are not."

"Screw the dealer. They are apparently completely incapable of performing even the most basic diagnostic tests on not just a car, but their flagship freaking sports car. The fact that their scanner shows nothing is really odd though, especially as the car has a GM calibration in it and not some aftermarket tune. Cars should not ping like this — bottom line."

We've racked our brains trying to diagnose the problem ourselves. Fuel filter? A clogged filter could cause fuel pressure to drop, making the car run lean... ping. Knock sensor? If the tech's computer showed no recorded knock but we've confirmed audibly that it is in fact there, maybe the sensor is bad.

Our research turned up GM Technical Service Bulletin No. 02-06-04-023A, dated June 2002. Condition: Some customers may comment on a mild to severe engine ping, usually worse during acceleration. Cause: This condition may be the result of corrosion of the rear bank knock sensor due to water intrusion into the sensor cavity. Correction: Replace the rear bank knock sensor and build a dam around the sensor using RTV to divert water away from the sensor.

Corvette owners should be able to go to their dealer for diagnosis and repair of this sort of issue. So we wanted to give ours a shot at fixing the problem. We wanted to give them the the benefit of the doubt. But they let us down. We've done our research. We'd like to find a shop that will do the same. This dealer isn't cutting it. We're headed someplace else.

We've had enough of the run around. We are going to fix our 2002 Chevy Corvette Z06 ourselves. At least that's the plan.

We're convinced (mostly) that our detonation problem is due to a faulty knock sensor. In the last Z06 post Mike Schmidt mentioned that our research turned up GM Technical Service Bulletin No. 02-06-04-023A, dated June 2002. Condition: Some customers may comment on a mild to severe engine ping, usually worse during acceleration. Cause: This condition may be the result of corrosion of the rear bank knock sensor due to water intrusion into the sensor cavity. Correction: Replace the rear bank knock sensor and build a dam around the sensor using RTV to divert water away from the sensor.

So we're going for it. Tomorrow morning at 9 am the Corvette, myself, Josh Jacquot and Jay Kavanagh are meeting at my house. And the wrenches will fly. Before he arrives Jay will buy two new knock sensors and a couple of intake manifold gaskets. I will also make a purchase; beer, which I plan on drinking while Josh and Jay fix the car.

By noon, the Corvette will either be fixed, on a flatbed, or just as sick as it was when we started this stupidity.

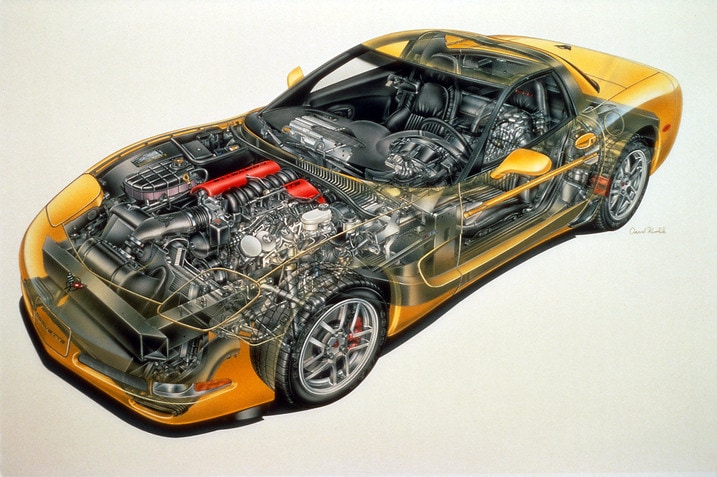

Wish us luck, we'll let you know what happens. In the meantime, enjoy this awesome David Kimble cutaway of the 2002 Corvette Z06 that I found on GM's media site today.

This will be part one of a three-part series as Jay Kavanagh, Josh Jacquot and myself attempt to change the knock sensors on our long-term 2002 Chevy Corvette Z06. The goal, of course, is to solve the Vette's chronic detonation problem.

Just in case anyone out there thinks this job is a walk in the park, let me remind all of you that this procedure includes the removal of the Corvette's intake manifold. Not exactly complex, but it isn't airing up the tires either.

The photo above is step 1: Remove the useless plastic valve cover covers.

More pics and captions await you on the next page.

Josh removes the air intake from the throttle body.

Josh looks for the 8mm open-end wrench he just dropped down into the bowels of the Vette's engine compartment.

Jay disconnects the Corvette's eight fuel injectors while mumbling something about pushrods and how much he hates working on a stupid truck engine.

Jay depressurizes the Corvette's fuel system.

After removing the 10 very long bolts that hold down the LS6's plastic intake manifold it was easily lifted up and out of the way. Um, I think that's rat poop.

It is rat poop. No joke, we found rat poop in the small crevices between the V8's intake manifold and cylinder heads.

A lot of rat poop.

Josh vacuums up the rat poop.

Josh continues to vacuum up the rat poop. Even with the largest shop vac on earth it took a while.

Part 2 is coming soon.

At the conclusion of Part 1 we left you with Josh Jacquot vacuuming up the rat poop we found after we removed our Corvette's intake manifold. .

Well, lets pick up the action with the image above, which is illustrating a key moment in the repair of our Z06. It's Josh asking Jay whether or not he likes his Grave Digger hat. What you don't know is that Jay is a hardcore Tom Meents fan and this exchange caused friction for the remainder of the day.

More pics and captions on the next page.

As you can see, Josh did a great job with my shop vac. Most of the rat poop is gone.

Before we continued to attack the rat poop, we thought it would be a good idea to tape over the ports of the cylinder heads. We've also pulled up the rubber caps and have exposed both knock sensors.

Here's a close up of the rear knock sensor. We don't see any of the rust or surface corrosion that we figured was causing our troubles.

Nope. No rust. But the lack of RTV Silicone told us that our car had not had this TSB performed, so we kept going.

This is us breaking for lunch. We had pizza.

Throttle body. This has nothing to do with replacing the knock sensor, I just thought it was a cool shot.

This is how we removed the knock sensors. That's Jay's hand.

Two knock sensors. Old on left. New on right.

And we installed the new ones, torquing them to spec of course.

Ever try to lay down a bead of silicone while some idiot that's had four beers is sticking a camera in your ear? Jay Kav has.

Not a bad bead Jay. By the way, that RTV belongs to Ed Hellwig. He left it at my house about a year ago. Don't tell him, he's sensitive about stuff like that. Plus, we used it all.

Now all we have to do is put the top of the engine back together.

Part 3 coming tomorrow...maybe.

Manifold is back on.

It's held down with 10 of these very long, but very small bolts.

Josh took off his Grave Digger hat to keep the peace. Jay reattaches something important.

Jay thinks that goes there, but the truth is he's not really sure.

What teamwork.

Right about now Josh got hungry again. Yes he ate the majority of a loaded extra large pizza less than an hour ago.

Almost done.

Jay is a real asset to Inside Line.

Done.

And then we test drove it. And the engine detonated just as it did before we started. In other words, we fixed nothing.

Next attempt at fixing it will come later this week. But we're putting down the wrenches and cracking open the Vette's ECU. Stay tuned.

No, our Z06 isn't fixed yet. But I'm tired of talking about detonation, so I'm going to change the subject.

Anyone out there like heads up displays? I don't. Never have. Whenever I get in a car with one I immediately disable it.

I've never understood the point. How is redundancy good?

Oh, I'm telling you this because our 2002 Corvette Z06 has one of these stupid things. And every time I climb behind the wheel I turn it off.

Besides that, and the detonation problem of course, the Vette is a real blast to drive and it's much more comfortable than you'd think. It rides well, its seats are soft and in the grand GM tradition it has a kickin' air-conditioning system. It's even easy to see out of.

And it sounds great. You can hear it a block away. The other morning it set off a couple of car alarms in our office parking garage.

This is a cool car.

When I sent Inside Line's Senior Editor Ed Hellwig shopping for a C5 Z06, I told him just one thing. I said, "Ed, choose any car you want. It just can't be yellow. It just can't have a detonation problem. And it can't have that ugly moulding on the doors. Besides that, you've got $20,000 to spend. Go buy something."

Well, two out of the three ain't bad.

Check out the photo on the next page to see what moulding I'm talking about.

Personally, I'd rather have door dings than stare at that eyesore.

You're probably as tired of reading about our longterm 2002 Corvette Z06's ongoing detonation saga as we are dealing with it. Here's the latest.

This morning we brought it in to Bothwell Automotive in Torrance, CA. These guys are not Corvette specialists per se, but they do service about 20 'Vette customers and countless other makes and models. Oh, and they know plenty about how to go fast, too — their lobby's trophy case is bursting with about a dozen and a half NHRA Wallys.

First, Steve Bothwell confirmed the detonation. Then he checked the fuel pressure to ensure that it doesn't have a bum fuel pump or clogged fuel filter. Fuel pressure checked out okay.

Then he hooked up the scan tool and checked the engine calibration to be doubly sure we didn't get snookered by the GM dealer. The calibration checked out too, so that's not the source of the problem, either.

With the scan tool, Steve observed the long-term fuel trims and noticed something that might be telling — the fuel trim for the right bank of cylinders is +8%, and the left bank is +13%.

Basically, over time, the ECU has "learned" (based on feedback from the oxygen sensors) to compensate for a general lean condition by commanding the injectors of each bank to stay open longer than normal. Apparently the LS6 can only trim banks of cylinders and not individual cylinders. This is a 2002, after all.

Anyway, a lean condition is a prescription for detonation. An underachieving injector (or two) per bank is the leading candidate as the cause of the lean condition, but at this point there's no way to know exactly which injector(s) is the culprit.

His recommendation is to have the injectors flowed and cleaned, which might be enough to bring a lame injector(s) up to par. If not, we'll at least know which one(s) is frumpy and can replace them accordingly.

Why the ECU doesn't acknowledge and/or correct the plainly audible knock activity remains a mystery. For whatever reason, it thinks everything is just peachy — no trouble codes, no knocksum on the scan tool. Go figure.

Seeing this dew pattern on the Corvette's trunk lid last night reminded me of this car's lightweight construction. And I'm not just talking about the fiberglass body, but the overall emphasis on keeping the weight down to a minimum.

This goes for all Corvettes of this vintage, but the Z06 took just a bit further by ditching the standard model's run flat tires, going to slightly lighter wheels, thinner front and rear glass and finally a trick titanium exhaust system.

All in all, it only amounted to a savings of about 50 pounds compared to a standard coupe, but the Corvette is already a fairly light car to begin with. That feathery feel is what makes the Corvette feel so distinctive on the road. After driving big heavy sedans all week, it's quite the noticeable difference.

We haven't had our particular car on a set of scales yet, but it should be around 3,118 pounds according to Chevrolet. The official weigh in should occur fairly soon, just have to get rid of that pesky pinging and it'll ready for testing.

What you see above is a flow report from RC Engineering of our longterm 2002 Corvette Z06's injectors. Not only is it a converted scan of a fax of a fax, but it looks like a bunch of alphabet soup. Here's a translation:

Our injectors were in pretty good shape.

Recall, Bothwell Automotive's diagnostic work suggested that a bum injector or two was causing a lean condition and making the engine ping.

The left column in the table above lists the flow of each injector on RC Engineering's flow bench rig, which applies a current to open the injector and delivers a pressurized test fluid for a specified amount of time. The fluid's volume is measured to determine the injector's flow rate. Here, the worst injector was only down about 5%.

After cleaning the injectors, RC re-checked the flow (right column) and they had all come up to spec (260 cc/min).

I'd love to be proven wrong when Bothwell reinstalls these injectors on Monday, but I'm skeptical that the cleaning process will solve the detonation issue. Even if the four worst injectors somehow managed to find themselves in same cylinder bank, it'd only be 4% lean on that bank and not the 14% reported earlier by the ECU. This suggests to me that the MAF is underreporting the actual airflow.

But I was wrong about the knock sensor TSB thing being the culprit, so don't listen to me.

This is sort of a non-update update on the Z06's pinging situation as it is still in the care of Bothwell Automotive. But I drove it yesterday and figured I'd keep y'all posted.

As RC Engineering's injector flow test report suggested, the cleaned injectors made little improvement once reinstalled.

Keep in mind that if the detonation had gone away as a result of this, it still wouldn't explain why the ECU refuses to recognize any knock activity. Even physically rapping the block doesn't register knocksum on the scan tool.

This is really the oddest part of the Z06's knock situation. As I mentioned earlier, there are no readiness codes, no DTCs, no knocksum — absolutely nothing anomalous according to the ECU. It thinks everything is just awesome even as the engine pings audibly.

Aware of this, Bothwell was planning on scoping the knock circuit while the injectors were out at RC, but he became deathly ill and was home sick those days. So he's doing that electron work today along with cleaning and checking the MAF in an effort to bring the fuel trims down to a more reasonable level. This fuel trim activity is separate from the knock detection/correction thing above, but the former isn't helping given the latter's current situation.

As for intake leaks allowing in unmetered air, we found none while reassembling the intake when we performed the TSB.

A word on the local Corvette specialists, since you asked: one of them doesn't service cars anymore, another took four days to respond to our inquiry, another was actually a Chevy dealer and not a specialist like we were led to believe, and the last one only does basic routine maintenance.

Is our long-term 2002 Corvette Z06's detonation spell drawing to a close? It appears so.

Bothwell Automotive checked out the MAF sensor and found some damage — one of the sensing elements was tweaked. Rather than just throw parts at it, Steve Bothwell figured he'd first try to repair the MAF sensor. He did so, and then re-checked the fuel trims. Lo and behold, the fuel trims came down from their previous 14% down to low single digits. The knock had vanished too.

Basically, the tweaked sensor dongas of the MAF made it tell lies. The MAF was reporting to the ECU that less air was entering the engine than in reality. This fib had two very significant side effects — it made the air/fuel mixture leaner at full whack than it should have been, and the ignition advance more aggressive to boot (sounds kind of like a non-adjustable SAFC...). Just the sort of conditions that are ripe for a ping.

Now, this still doesn't explain why the Z06 apparently can't hear knock, but if the source of the knock is eliminated (as it appears to be), then we're fairly okay with it.

Also, the MAF damage was caused by a thing, and that thing may have kicked the snot out of the MAF on its way into the engine. Seems unlikely. Our Z06 feels quite strong, and such a snot-kicking thing would cause it not to be so. The damage was more likely done by mishandling. Perhaps the previous owner's mechanic was some kind of ape.

I'll be giving the Z06 a good rogering today to fully convince myself of its knock-free-ness, just to be 100% certain. You know, in the interests of science.

You don't seem surprised by that statement. I am.

As much as Corvettes squeak, Corvettes leak. Every Corvette press car I've had washed, has leaked. The C5 parked in my garage leaks when you take it through a car wash. It also leaks when it rains. And guess what, so did my 1994 TransAm, which did not have t-tops, as did The Brunette's 1998 Z-28, which did. Notice a trend?

They've all leaked in relatively the same spot too; along the trailing edge of both doors and up where the side windows meet the roof. I've always chalked it up to poor design of the door seals, poor assembly and poor fit and finish. So when I was given the Z06 to shake it down this weekend, I took it through a touchless car wash, just for kicks. And much to my surprise, it didn't leak.

Nice.

If you're successfully able to get into our Z06's trunk, this is the strange sight you will see. The Z06 and all similarly bodied C5's feature this weird combination of Corvette hatchback coupe and convertible body style. You get the drop-top's traditional trunk lid, but then you have most of the hatchback's expansive space accessible from the passenger compartment. Weird, right?

Word is you readers want more driving impressions of our 2002 Chevy Corvette Z06. Well, I'm here to deliver.

Ready? Here goes.

Our 2002 Chevy Corvette Z06 is freakin' fast. Like snap your head back, blaze the tires, scare old ladies, land in jail, sorry officer, tear the skin from your face, maybe I shouldn't do that again but it was really fun fast. It explodes with speed in any gear at any rpm. Redline more than one gear and chances are you're well over the speed limit. Nail it off the line with any kind of rapid clutch engagement and its rear Goodyears are worthless. In other words, its exactly how cars should be.

Last week I was digging around in the garage for one of my old Bacce Ball trophies and found an old car mag back from August of 2001. In it was a first drive of the 405 hp 2002 Corvette Z06. It says that GM claimed a 0-60 mph time of 3.9 seconds, a quarter mile blast of 12.4 seconds at 116 mph and a top speed of 168 mph.

And our car really does feel that quick. The Z06 is easily the quickest car in our fleet right now, and it'll smoke our long-term Camaro SS, which is rated at 426 hp, but weighs slightly more than the Empire State Building.

We'll track test our Vette soon to see if it can match those performance numbers with 50,000 miles on its odometer. Stay tuned.

I finally got in our long-term Corvette Z06. Though I could've had the car earlier, I wanted to wait until its pinging problem was cured. Now that it has a clean bill of health, I figured I'd be able to enjoy it as the creators of its 405-hp V8 intended. I'm sure I'm not shedding any light here when I say "Damn, this thing is fast!" but I'll say it anyway.

Blasting down freeway on-ramps and out of corners reminded me just how great an old two-valve-per-cylinder, pushrod V8 can be. The vocals (sorry, too much American Idol) from the exhaust are cool too — quiet enough when you're just tooling around and downright rocking with a gutteral roar when you're leaning on it.

Follow the jump for other observations, some of which aren't as well, obvious.

— I checked the oil and found the 'vette was down a quart. Though two quarts of Mobil 1 were secreted in the trunk (see below) I stopped by Pepboys and got the vital synthetic fluid (cost: $7.49). Thankfully, the LS6 V8's dipstick and oil fill cap were very easy to access. The oil fill opening is dead level and large enough so I didn't spill a drop. Conveniently, it's also just larger than the bottle's neck, so I stuck the bottle in there upside-down for a few minutes to get the last bit of oil out (and minimize the hurt to the earth).

— This being the top-dog performance Corvette, I expected a stiff, bone-jarring ride but my finicky back was glad to discover that wasn't the case. The Z06 was actually pretty compliant over the crappy roads in and around L.A. (La Cienega, I'm looking at you). And it sticks like a cat to a drape in the corners — there's more capability here than I was willing to exploit on public roads.

— When I went to put my gym bag in the trunk, I discovered the lid barely moves when you hit the release. As the trunk is open to the passenger compartment, I saw that there were a few quarts of Mobil 1 stashed in its rearmost left corner, but I couldn't get to them unless I crawled back there, hence the trip to Pepboys. Later in the day, it dawned on me to try shutting the door quickly (with windows up) to pop up the lid, the theory being that if the car is airtight enough that would do the trick. It did. My "Nice going Johnny!" moment was short-lived — I found out later that Jay Kav already discovered this method and even made a short video on it.

— The center console lid can't be opened all the way if the parking brake is up. So after parking the car and pulling up the p-brake, my instinctive flip-the-lid-and-grab-my-wallet action was thwarted time and again, until I remembered to open it first and then set the brake. Furthermore, it gets pretty warm in that compartment so I wouldn't advise stashing any chocolate bars there.

— I love the meaty feel of the shifter but dislike the 1>4 skip-shift (big surprise). I got around that annoying "let's lug the engine to drive up our fuel economy estimates" feature by either accelerating a bit more briskly in first (so it didn't kick in and thus really defeating its purpose) or, if I took off more gently and it did kick in, giving it a throttle blip mid-shift to cancel its action.

I've been driving and enjoying our long-term 2002 Chevy Corvette Z06 for the last few days, but I have one significant gripe: The black plastic front spoiler (highlighted above in red) hangs so low it scrapes on everything.

And I mean everything. Every driveway in, every driveway out. Every speed hump up, every speed hump down. It'll even touch down on road dips or intersections than have any kind of elevation change.

It's obviously is meant to do that. That's why Chevy makes it out of flexible plastic, but it's hard to look cool when your car is crunching against the ground constantly. Pedestrians and other drivers look at you like you're a fool. A fool that just took out his front end. The only way to avoid it is to come to a complete stop and roll over the obstacle, and that only works about 50% of the time.

To this extreme, this problem is unique to the Vette. No other supercar I've driven in the last 10 years hits the pavement this often, and that includes our old long-term 1984 Ferrari 308.

I have a love/hate/like relationship with the shifter in our long-term 2002 Chevy Corvette Z06.

I love the way it takes a heavy hand to operate and the way it actually feels like a true mechanical connection to the Corvette's drivetrain.

I hate the way it fights back when the light turns green and you need to find first gear quickly. It's not a huge issue but pulling it to the left gate from neutral does take little too much muscle.

I like the Vette's shift knob, which isn't really round, but it also isn't quite square. And I like the shifter's height, but wish it was a little shorter.

So I had our 2002 Chevrolet Corvette this weekend and I couldn't figure out how to switch the display from showing coolant temperature to the tripmeter...

Just kidding. I know you guys were looking to read more driving impressions on this car and although I'm not the target market for the Z06 I did get the chance to drive it so figured I'd just share what I thought for what it's worth.

I found the Z06 easy to shift, handle, drive. Even at a really low ride height, traffic didn't intimidate me. With all that power I could get myself out of situations right quick. WEEEEE! And so much loud, raw power. Radio off, let me listen to the car which burbles loudly even at just 2,500 rpm. On this sunny weekend, the only thing I really had to be careful with was going over bumps and stopping too closely to the car in front of me as the front end is a lot longer than I thought.

But things changed the instant I had to drive the Vette in the rain this morning. Some minor wheel spin at the green light wasn't so much a concern as was the constant shimmying of the car on the wet freeway. Couldn't tell if it was tramlining the grooves on the road or if the gusts of wind were batting it around but it felt like the car would lose control at any second. Editor Jay Kavanagh said he had experienced the same thing when he drove it in the rain: "Our Z06, for instance, is downright eerie in the wet even in the absence of hydroplaning." He blamed the dampers.

Whatever the reason, I didn't like it. I took my favorite curve of the 90 freeway oh-so carefully especially when I knew that hitting the gnarly seam on there would make the car dance. I definitely felt compelled to drive wayyyy more conservatively than I do in most of our cars.

So suffice it to say, wouldn't trust this car in the wet stuff but it's fun to drive all the other 364 days of the year in L.A.

PS: Just took a picture of the instrument panel since no one had posted one yet.

Our long-term Corvette Z06 hit 45,000 miles yesterday. This was after I'd spent over 200 miles in the car and I'm happy to report all systems are functional...mostly.

The trunk release that doesn't actually release continues to annoy me, the always-shifty shifter feel is disappointing, and the 7/8 scale seats that don't fully support adult human bodies are a travesty. But it's still a powerful and capable performance machine that can smoke the majority of performance machines on the road, even those that are newer and more expensive.

This Z06 reminds me of two Corvette trademarks. First, the basic platform is excellent, but the execution of the details leaves something to be desired. This fact leads to the second point: GM's "sports car" has always been, and will probably always be, more of a two-seat muscle car than a true sports car in the traditional sense of that word.

So I recently commented on how easy it is to get comfortable in the Mazdaspeed 3. And the Z06? Well, it takes a little more wrangling of the controls. I've set the memory several times, but someone always screws it up by the time I get in it again.

So last night, I get in and everything feels screwy. A twist of the knob here, a pull of a lever there and the Corvette slowly started to get comfortable. I still can't decide which notch in the tilt steering I prefer, but you know, once you're situated it's not a bad place to be.

Sure, the seat itself is too soft, but I like the view and the proximity of the controls. The pedals feel right and the shifter feels really solid, like you can rip shifts all day and never feel like you're hurting the thing. And isn't ripping gears what this car is about? Yes, yes it is.

Wow, what a car.

"It's a beast." warned Scott Oldham when I told him I had the keys to our 2002 Z06 for the weekend — the first time I've been able to drive it without fear of knocking the engine into pieces. "Be careful."

And he's right, the Z06 is a monster. It's scary. Scarier than a new Z06. Scarier than a new Viper. Not because it's faster, but because it's sort of bad and not as well sorted as those other, newer cars. Nail the gas from virtually any speed (and we're talking really nail the gas here, no feathering or gradual application, just stomp it to the floor.) and the Z06 claws and shimmies and shakes and sort of scuttles it's way forward hunting for traction. The chassis twists and the steering gets spooky light and it's just awesome. Hit a bump or pavement inconsistency during that and hold tight, it's about to get all sorts of crazy.

And it's in this vein that the Z06 excels, doing something I wish the new Camaro would do: Roll along near the middle/top of first, 20-30 mph and, again, like a goon, just stand on the gas. From this speed the Z06 absolutely melts its rear tires. Do it right and you can leave rubber from a roll. The Camaro doesn't do that. The Camaro just goes forward faster.

Sure the Z06 is stupid fast when you drive like a grown-up, but who wants to be one of those guys all the time? Not us as evidenced by our recent burnout competition, that, btw, would have been owned by this Z06.

Well, not technically speaking. Actually, our Z06 just makes you want to do dumb things.

Like launching from stoplights with the tires at full smoke. And I mean every stoplight. Corner exit tail slides are also ridiculously easy and nearly impossible to resist. Just ease into that 400 pound-feet of torque and away you go. On the sidewalk, old women scowl, dogs bark and children squeal, it's great.

It's the kind of fun you expect from a car that has its horsepower spelled out on the quarter panel. Kind of a shame that more people don't appreciate how much fun can be had in a car like the Z06. Glad I'm not one of them.

Just had my first evening in our long-term Z06, and I love the layout of the pedals. As Ed has written, the seating position is bit weird, and as Scott has written, the shifter won't have you rushing the gearchanges.

But the pedals are perfectly set up for heel-and-toeing. It's very easy to let your big toe do the braking while the right side of your right foot prepares to blip the throttle.

When I bent down to take a photo of the pedals this morning, I noticed that the clutch and brake pedals are beautifully finished. They have a more rough-hewn, function-before-form look than the polished pedals that are fashionable today, and I think they're better for it. So instead of 1 photo, I took 3 photos of this well executed detail.

You probably saw Donna's post earlier this week asking you about your interest in a weekly feature of our readers' cars. As such, I thought I'd share some general tips with you on taking photographs of cars. Assuming we start this weekly feature, your chances of being selected will certainly be influenced by the quality of your submitted photos.

You'll find the tips on my "How To Take Pictures Of Your Car" post over on the Edmunds CarPool blog.

Dyno Tested

I've been wanting to take our long-term 2002 Corvette Z06 to the dyno since day one. A certain detonation issue sort of sidetracked our plans, though, as you really need to avoid full throttle in those circumstances... unless you like engine salad.

But that's all behind us now. We've since been relishing the ability to hoon the Z06, which we've found has an aptitude for powerslides and can slither its rear end on a straight road with nothing more than a third-gear roll-on.

This car certainly feels strong. Always has. Without further ado, here's what we learned at the dyno.

Hit the jump for the dyno chart and photos. And pardon the video quality above, which was done not by our usual crack video team but by some hack with a tempermental and sub-par point-and-shoot.

When new, the Z06's 5.7-liter pushrod V8 churned out 405 horsepower at 6,000 rpm and 400 lb-ft of torque at 4,800 rpm. That's as measured at the crank.

Here's what we found at the wheels of our silver long-termer, as measured on a Dynojet 248 chassis dyno:

The rev limiter intervenes at 6,500 rpm, which is just the same as the engine has long since stopped increasing power at this point. Still, it's worthwhile to shift this car at redline since you'll maximize average power this way.

Peak power of 382 horsepower arrived at 6,200 rpm and its peak of 375 lb-ft of torque was produced at 4,900 rpm. This was the stabilized output achieved after four fourth gear runs on the dyno. A 1% SAE weather correction was applied.

Not bad, eh? When you consider that the driveline saps some 13-15% of the engine's output, I'd say time has been kind to this car when it comes to its ability to turn ol' Dino into heat, noise and forward motivation.

Either that, or all LS6s are similarly stout. Anyone know how well these Dynojet results stack up against other bone stock Z06's with similar miles on the clock?

After coming to the end of an hour-and-a-half drive, my fiancee declared her opinion of our long-term Corvette Z06: "It just feels beat up."

I thought about it and had to concur. The Z06 indeed feels like a beat up super car — partly because it has more than 46,000 miles on the clock and partly (possibly mostly) because that's just how C5 Corvettes are.

You open the door, it creaks. And then it won't stay in place. You sit in the squishy formless seat and it feels like it's lived its life under the butt of a 350-pound man named Walt. You roll down the window and the entire door panel flexes inward. You open the trunk using air pressure. Almost every interior panel is misaligned, hard, hollow, cheaply grained or have nasty flashing on its edges. The center console cubby door struggles to open. Monumental amounts of road noise pour into the cabin from the trunk.

So it feels like a beat up super car, but it's still a super car. You sit practically on the pavement like in a super car. The view over the long, wide hood is pretty indicative of a super car. The look may not be Gallardo-like, but I still think the C5 looks pretty bitchin'. The growl of engine and exhaust? The power? Those goes without saying.

So our Z06 feels beat up, but given its price, maybe you could tolerate that if it was just your weekend car. After all, what one man considers flaws are what another calls "character."

According to my dictionary: Gage: n. something, as a glove, thrown down by a medieval knight in token of challenge to combat.

So, I'm assuming if you're at a red light, and some kid next to you in a lowered STi starts revving his engine, you can hit this button and something like a sun visor will automatically be ejected and slapped to the pavement as a signal that you accept his challenge.

No? OK, fine. Chevy used an antiquated spelling to fit this particular button rather than swap it with the "trip" button below it — which has plenty of space for a "u". Any way you cut it, it's wrong.

Last night I had my first chance in the Corvette Z06. My first impression is that it feels older than it is. It's only a 2002. That's newer than my personal car, but it feels well used.

I'm glad, however, that the original owner got his money's worth while owning it. I feel bad for my car at times when I pass it in the garage and walk over to a Corvette instead. A car should be driven.

Here are my general first impressions:

Spooling through our underground garage, I kept triggering the traction light, so I figured I better calm down. I wasn't going fast but all of those turns drove the Vette crazy.

But I left the office late and traffic had settled down. I sat at the light at the top of the freeway entrance and smiled. The empty road looked out enticingly before me and I was sitting on the back of a bull. The car shook with anticipation. This Vette really moves.

The shifter takes some muscle. No light little German shifting in this baby. The distance from first to second seems like a yard. But you connect to it and really feel you are in command of the car. It's very satisfying.

Much to my dismay, I discovered our Vette has that damn 1-4 skip shift feature. It took me by surprise after I exited the freeway. I really dislike that and the car doesn't seem to like it either. After that I just held onto first until the light went out. I like feeling that travel from first to second.

This morning's commute was the complete opposite. I even left late to avoid the rush. But the travel gods were against me and I got stuck at every red light on every hill possible. But this Corvette doesn't roll back much, which is nice. I expected an 8-year-old car to go into backwards freefall.

Like the shifter, the clutch requires some muscle. Good thing I had all of those ballet lessons. By the time I got to the office, my calf had a good workout and my left foot was actually getting numb from the pedal. But small price to pay for such a great ride.

I apologize, I forgot to take a picture. The one above is by Kurt Niebuhr.

Before we send out 2002 Chevy Corvette Z06 out to the test track, we wanted to make sure this 45,978 mile Corvette was aligned properly. We haven't experienced any driving anomalies, but crazy things happen at 10/10ths. Plus, those tires are big and look expensive, might as well make sure we're good.

So we took it to Stokes Tire Pros here in Santa Monica. They know us and let us cut in line (take that, guy with the Subaru wagon) — we just wish they'd give us a price break. An alignment there cost $110.

Follow the jump for some nerdtastic alignment numbers!

Before After

Front Caster: L: 7.80 L: 6.97

R: 7.72 R: 7.36

Camber: L: -0.91 L: -0.81

R: -1.16 R: -0.79

Toe: 0.10 0.01

Rear Camber: L: -0.60 L: -0.84

R: -0.80 R: -0.85

Toe: 0.19 0.01

After my softball game last night, I was standing around the Z06 with our right fielder when he mentioned he'd never been in a Vette before. I told him to get in and he plummeted into the squishy driver seat with a declaration of "it's so low." As a former M3 owner, I don't think he was impressed. As he climbed out, though, he must've used the steering wheel as leverage to get out and activated the steering column lock.

When I started the car, the gage cluster read-out ominously said something to the affect of "Pull Key; Wait 10 Seconds." I was going to ignore it (probably not the best idea), but when I went to move the wheel I found it was locked. This engaged a new read-out saying "Service Steering Column Lock." Uh-oh. So I pulled the key, waited 10 Mississippis and tried again. No luck, still locked. I tried it two more times, waiting longer each time. No luck.

At this point, good buddy and catcher SubyTrojan entered the scene. "Vette's broken," I declared through the window. We chatted for a few moments about possible causes, solutions and just abandoning the Z06 at Cheviot Hills to become a bird sanctuary. Then I said, "OK, let's just try this all over again." I got out of the Vette, locked the door, waited a few seconds, unlocked the door, got in and fired it up. Low and behold, the steering column lock was disengaged. No service (or tow truck) required.

To double check, I locked the steering column again this morning, but it unlocked once I started the engine. Go figure. Though I have to wonder how common this issue is when the trip computer has both a specific warning and solution for it. Hmm.

Oh well, I guess this just proves once again that if you want to fix something — anything really — just unplug it and re-plug it back in.

Every time you crawl into the seat of this aging Corvette, the leather squeaks and groans like you're getting into your dad's old recliner, the one down there in the basement in front of the used-up TV from the 1980s. Whatever the high-tech environment of the modern sports car is meant to be, sleekly designed and ergonomically correct, the Corvette is the opposite.

Which is exactly the point.

The Corvette is meant to be as familiar as that old leather recliner, although maybe a patch of duct tape on the upholstery might be going a bit too far. It's a sports car, not a piece of art. Especially as a used car, all the pretense has been dropped, which has always been the most objectionable part of the whole Corvette thing anyway.

Americans have always been ones for stripping away pretense. In the first decade after the turn of the 20th century, they would make a sports car by throwing a car's bodywork in the barn and then lashing a seat and a fuel tank to the motorized buckboard that remained, which pretty much describes the iconic 1912 Stutz Bearcat. When the Ford Model T came along, they did the same thing and then bolted an overhead-valve cylinder head to the engine besides. Before and after World War II, all those fenders came off the Ford Model A.

Sadly, you can't pull off all the Corvette's bodywork. If you could, you'd discover that the car is actually better looking underneath, a stunning exhibition of compact packaging and component integration that is very different from any British, German or Japanese sports car you've ever seen.

You don't treat a Corvette as if it were special. You just drive it every day, enjoying the things that make it friendly and the things that make it eccentric, so you know just how long the brakes will last before they get hot and you know when the transmission wants to give you second or skip-shift to fourth.

It's just your car, a little ragged and a little tired, but no quit in it and still able to make anything else look not only slow but also pretentious.

The only way this car could be better would be if we had a fender finished in primer gray.

I don't think it's a secret I'm not a Corvette fan. However, that status comes entirely from driving the thing. Prior to my time behind the wheels of umpteen Corvettes, I actually thought they were pretty cool. I was never exposed to (or just never noticed) the owner stereotypes of white-haired men or greasy dudes with gold chains. So when our very own Brent Romans got a Vette, I was a little confused as to why he seemed to be defending the purchase. 'Why?' I thought, that's awesome.

Maybe its because of where I'm from. When I lived my formative car guy years in Indianapolis, C5 Corvettes were all over the place and certainly seemed like the sports car of choice. I thought they were a pretty cool car — even in 1998, when a certain notorious pace car edition was roaming around (you'd be surprised how many people had them). Earlier when growing up in Toronto, the fastest car I ever got to drive in was a family friend's 1980s C4 vintage. I thought that was really cool.

So I wouldn't buy a Vette; it's just not my cup of tea. Is it cool, though? I'm saying yes.

That's too much information. But no, the heads up display on our Z06 isn't broken — well, it's broken, but it's functioning as intended so it's not more broken — that's just what it does when the sun hits it in just the right spot. And just the right spot happens to be my entire morning commute.

There doesn't appear to be a way to avoid this without putting something — I used our Long Term Fuel Log — over the hole on the dash. Of course, this results in the reflection of a fuel log on the dash to fly over the IP and hit me in the face when I get a chance to use the big V8.

"Sorry, officer. As you can see, my gauges are broken. I was going less than 188, right?"

I almost didn't take our 2002 Chevrolet Corvette home for the weekend because as much as I have fun driving it, it's kind of a pain on city streets. The Vette is just too big for this city. There. I said it.

So all weekend, I ended up parking in spots far away from my intended destinations since those were the only spaces roomy enough to accommodate it. And never mind that its front end dips down so I can't really see where it ends and I fear that I'll scrape or bump it into the car parked in front of me. In the above picture I thought I was a lot closer to the car in front of me than I actually was.

If this were a city of free parking lots or I didn't have an aversion to valet, my only issue with its size would really come up when driving down residential streets. With cars parked on the sides and other cars coming the other way, I instinctively hold my breath and squeeze my arms into my sides as if that will magically make the Vette smaller so I can get by this oncoming car unscathed. Then I realize I'm doing that and instead move the car as close as I can to the side and wait until the other car gets by me. Almost as worrisome as driving a truck.

Just for giggles I looked up the dimensions of a 2010 Porsche 911, which actually seats 4 (2 adults and 2 kids, really).

2010 Porsche 911 — Length: 175.6 in. Width: 71.2 in.

2002 Chevy Corvette — Length: 179.7 in. Width: 73.6 in.

The Porsche has managed to package a working backseat into less overall length than the Corvette.

In any case, for me the Vette is not a practical, everyday urban runabout. Traveling open highways and byways? Definitely. Rushing to meet a friend for lunch in the heart of West Hollywood? Nuh uh.

Though Sir Mix-A-Lot may beg to differ, a lot of car enthusiasts think the C5's butt is simply too big. The upshot is that this sports car's hatch (or trunk if it's a notchback body style like our Z06 or a ragtop)) has a massive capacity — 25 cubic feet for the hatch and 13 cubes for the trunk. Still, it's the least flattering aspect of the C5's style, and unfortunately the notchback version only emphasizes the height and breadth of that bountiful booty. However, as any artist who has used trompe l'oeil can tell you, the eye can be tricked.

I recently saw that yellow Z06 at a car show and though I'm usually not a fan of body kits, liked how this cleanly executed aftermarket rear fascia visually reduced the big butt's mass. Whereas the stock 'vette's rear end has about an acre of monotone body, this modified Z06 has it broken up and made more attractive via a full-width black taillight panel. Though it's still wide, it looks much sleeker than the factory setup. The only change I'd make would be to black-out the lower portion of the fascia above and next to the exhaust outlets.

What do y'all think? Big improvement or not?

When you're returning home from a press trip and your flight doesn't get in until 7:34 (PM) you're pretty much assured of being the last man out of the Edmunds.com parking structure. You're also likely to be last on the priority list, meaning you get whatever car is left after everyone else raids the test fleet keyring.

What that meant for me a couple nights ago was walking out to our parking area and seeing a lonely Corvette Z06 waiting for someone to show it some love. I'm not sure if this is a reflection of the Z06 being undesirable or our other test cars being very desirable, but after using the car to drive home (and work the kinks out of four flights in the previous 36 hours) I have to believe the latter.

For future reference, any time the rest of you guys want to leave the Z06 for late-nighters like me, that's just fine.

Yep, that's our Long Term 2002 Chevy Corvette Z06 parked in the Corvette Corral at this weekends Mazda Raceway Laguna Seca ALMS race. I didn't register for the Corral, but managed to sneak into (read: They saw I had a corvette and put me here without the super-special green pass) anyway.

Including a couple of pointless excursions and a getting lost 2,658 times while in Monterey, I put 909.1 miles on the Z06 during 16 hours and 15 minutes of seat time. Average MPH was 55.9. And during that time I averaged a staggering 22.6 mpg with a best of 25.9 and a worst of 20.3. 20.3! With 405 horsepower! And me behind the wheel, lost in a strange little town...awesome.

But beyond the numbers, I really fell for our Corvette during this trip. Road noise at freeway speeds over California's crummy concrete gets old, but everything else was an absolute blast. The shifter is deliberate and the pedals take some effort, but put them together and you're rewarded with a noise...oh the noise... let's just say that after a few hours hearing Corvette C6Rs and their E85-fueled 5.5L V8s thunder around, I was still grinning when our Z06 roared.

Would I want more supportive seats? Sure. But consider this: I sat on a shoehorn for 4 hours — 4 hours! — and had no idea. Now that, friends, is comfort.

Give it an iPod hookup and this is, hands down, the best car in our fleet. Period.

I was in a rush coming from the grocery store. I didn't want to eat dinner at 8 and what I was planning took two hours to cook. I had to get a move on.

I swung open the door to our ZO6 with five plastic bags worth of groceries in hand and tried to slide it. Instant pain in the ass. Literally. No, not trying to handle the groceries and getting into the car at the same time, that damn massive seat bolster. I smacked my tail bone right on it trying to get in!

I rolled over the seat both laughing and crying. I'm not the first victim of this thing, but I am the latest and probably the most in pain. The bolster is nice when you're in the seat, but ridiculously big and in the way while trying to get in.

I got dinner finished in time but I still wasn't totally comfortable so I took a siesta. My lady came home and saw me laying face down on the bed. After I explained what happened she busted out laughing right in my face.

Awesome. That's love right there.

When I said the other day that our 2002 Corvette Z06 was the best car in our fleet (save for its lack of iPod integration — an easy aftermarket fix), I wasn't kidding. I want one. Bad. Real bad.

But, because I'm a young guy with all of my hair, I just can't do the gold chains and embroidered leather jackets. So instead I went for something classy and hip, a skull! Corvette Racing's Bad Boy Corvettes mascot, Jake, to be specific.

So until I can swing a C6.R or Z06 Carbon, I'll just grab the keys to this at every opportunity and always keep the hat at my desk, just in case.

Cammed Z06? Yes please.

Turn up your speakers. Watch. Repeat.

Ours needs to sound like this. Now.

Corvette is a brand, not just a car.

From the beginning, GM set the Corvette apart from Chevrolet. That's why Harley Earl's design team worked so hard to create a unique logo in 1953 (complete with the European visual imagery Earl liked so much). That's why Zora Arkus-Duntov's famous memo about Chevrolet and the enthusiasm of young hot-rodders for performance earned him lasting influence as the Corvette's first chief engineer.

Because Corvette is a brand, not just a car, everyone on my street has come by asking about a ride in the Z06. Just like the guy a couple doors up who has had a series of American cars, from his 1966 Pontiac GTO to his late-gen Thunderbird. He's always wanted a Corvette.

But that's just the trouble.

Everyone I meet says that they've always wanted a Corvette or always wondered about a Corvette. The strength of the brand has given them lasting awareness of the car. Yet almost never do I meet someone who says that they're going to get a Corvette. Everybody knows the brand, but too few know the car.

And that's why this used Z06 with 48,305 miles on it is such an important automobile. This is a Corvette that is cheap enough to own. It's not some exotic automotive icon; it's a car that you can drive. As my friend Bill Cooper, the winner of the 1989 Corvette Challenge racing series, frequently tells me, you can want a Porsche, but you can drive a Corvette. It's the difference between $80,000 and $20,000.

If I were the Corvette guys, I'd be working hard on the certified pre-owned program and I'd be telling everyone to visit guys like Corvette Mike. Even better, I'd be reminding people that one day soon you'll be able to buy a Corvette Z06 like this one for $15,000

Managed to snag a pic of this alert in our 2002 Corvette Z06 just before pulling out of our parking garage. It came on about 20 seconds after key-on and shortly thereafter was replaced by another alert reporting that everything was just peachy, or something like that.

A brief check suggests that this alert has nothing to do with warming up, per se — logical, since there's nothing to warm up. Rather, the system, once you're rolling, does quick check of various chassis sensors including the steering angle sensor. It needs a brief straightaway to check this guy.

Since our garage is a series of slow 90-degree turns immediately after another, the system couldn't get a proper read on the steering angle sensor in the allocated amount of time. Owner's manual says this is normal and that the Active Handling is not operational during this period.

No worries here. I usually go full stability-off commando-style but hadn't yet hit the buttton this time. Anyway, I don't beat on cars til the coolant is fully warmed up (and then some — that way the oil can get warm too), which takes far longer than it took for the Active Handling to be ready in this case.

OK, stick-in the mud warning here. It's pretty incredible to think we could get a Z06 for $20,000, particularly one that still goes and sounds as good as this one. Whenever the little niggling details about this car started to get on my nerves over the weekend, planting the throttle seemed to do the trick, adjusting my attitude if not the car's as well.

But I do hold those niggling details against our Corvette Z06 — so much so that it wouldn't be a good deal for me no matter how tantalizing the price. Yeah, the disintegrating interior is part of it, but it's also the steering, which feels like it's at the same heavy effort level at every speed yet is still low on feedback. I never feel like I'm tuned into what's going on with this car, and I feel like that's not too much to ask even for just $20 grand.

And although the packaging of the car may be something to marvel over from a performance standpoint, it makes for a cramped cockpit with almost no storage space. There is, at least, some room for cargo in the generously proportioned Corvette butt.

I'm about to complain about the ride, too, but I'm going to hold that one until we replace the Goodyear F1 Supercar tires, which are just about done. With fresh new tires, I might very well be able to cross this one off my bellyaching list.

It was a pretty oppressive commute last night. The 10 Freeway was bumper to bumper, making my 8-mile commute take about an hour. Still, the Vette held up pretty well. After I exited the freeway, though, th shifter started giving me a little grief.

When a traffic signal went green, I tried slipping the shifter from neutral to first. Nope, it was having none of it. I dropped it into second gear easily, then tried to ease it into first again. Nope. So rather than suffer the wrath of the impatient drivers behind me, I rolled out in second gear. Further down the road, at another traffic light, it dropped right into first with no problem. But the shift from first to second posed a similar issue. It wasn't a skip-shift situation, either. It just flat out refused to engage second gear. Ok, fine, third gear it is.

My old SVT Cobra had the same problem, but I attributed that to abuse on the racetrack and a Hurst short-shifter I had installed. I'm guessing this is just wear and tear on the Z06, though, since other Vettes I've driven of this vintage we're fine when they were new.

Has anybody else out there had this problem?

Yesterday wasn't a good one for me. It started early with dude flaking on me for stuff I'm selling on Craigslist followed by a crazy lady driving the wrong way up a freeway entrance on my way in to work.

After nearly a 14 hour day of work I got back to the office from a shoot around 9:30pm. I put all my gear away and was ready to leave the office a half hour later when realized I left my keys in the car I shot. Which left with the editor. I called my lady and she didn't answer. I called the Editor and he didn't answer. (Insert loud French expletive).

Realizing I was stuck at the office late at night after a crappy day was the turd cherry to my poo-poo Sundae. I wandered upstairs in desperation to see if there were any cars left and there, shimmering in the darkened office, were the keys to the Z06. To say I was in a bad mood was an understatement. The Z06 was the antidote.

Sitting at the light waiting to get onto the freeway I was fuming. The light turned green and I punched that gas hard. The headlights splashed back and forth across the road as I broke the end out in a cloud of smoke. I ripped through first to near the rev limiter, blowing past a taxi on the entrance ramp like he was standing still. Pumped it through second gear, screamed through to third and I blazed down the 10. A big grin spread across my face as I shifted into fourth on the empty freeway.

The sound of that American beauty when it's running hard is pretty sweet. When you ease it down into fourth the snarling Pit Bull of an engine settles down into its bed and becomes a calm, submissive puppy.

By the time I made it home, I didn't care about the bad day I had. My lady let me in the house and everything was good. Thanks, Z06. You really know how to cheer me up.

I usually don't get the opportunity to live with a car more than one night at a time. Does that make me an automotive gigolo? Nah. In a rare moment yesterday, keymaster Schmidt asked me to sign out a car for the night, as well as for the weekend. Four days with the same car? The choices were slim, but diverse, including the Mazdaspeed 3, Flex and Volvo XC60.

My choice? The Vette. Magrath's got some sort of love-fest going on with it, so I need to see if there's something to it. I do like the wallop of power and furious engine note, so we'll see how much of the rest of the car will endure itself to me. I probably won't be wringing its neck too much, though, because there's this nutty Yamaha R1 that I have for another three weeks. With any luck, you'll see it popping up from time to time.

I spent the last four days with the Z06, and yes, I do like it a lot better than before. I didn't take it into the canyons for a bombing run, I mostly used it to blast from one side of town to the other. But here's what I discovered.

It's fun. Really fun. But in order to have fun, I'd have to break the law. At least for me, the Z06 is only entertaining when I'm roaring at full throttle or sliding it sideways (as illustrated in the poorly photoshopped image above). With the pedal down, this thing is way too loud for my tastes. Don't get me wrong, I love the way it sounds, it just attracts too much attention from the good men and women that keep the peace. Oh how I wish I had a "get out of jail free" card.

For fun this weekend, I opted for the Yamaha R1 that we have downstairs. Talk about bang for the buck! Plus I got all that entertainment by bending the law, rather than breaking it altogether. More on that later, stay tuned.

Again, I had a long day of work and I knew I'd be stepping out of the office doors well after 9:30pm. I purposefully chose the Z06 for my ride home with the "L.A." version of an empty freeway. The Z06 wasn't meant to idle in traffic.

I hit the lights and with a squeak they tumbled open. Instantly it reminds me of a debate I had with a friend some time ago about about the redesign of the Miata. I preferred the new integral style whereas he preferred the old pop-ups. He felt the pop-up gave it character that the new generation lacked. I felt the new style returned to the sexy British race car lines and improved the looks.

What about our Corvette? Same deal as the Miata, it switched from pop-up to integral. Which do you prefer the look of? I don't think anyone can deny that starting up the car at night and having the lights swing open is a little cool and sinister. But is it that cool?

Failing electronics/mechanical issues aside, do you prefer the classic pop ups or the sleek integrals?

Of the cars in the long-term fleet right now, I think we could all agree that the Z06 ranks near the bottom for long-distance freeway driving comfort. Editor James Riswick best described the driver seat as "a squishy and formless seat [that] feels like it's lived its life under the butt of a 350-pound man named Walt." The considerable and constant tire roar from the rear is complemented by what sounds like small arms fire when you drive over pavement cracks and tar strips. There's no interior storage, satellite radio or auxiliary audio jack. Oh, however did people tolerate the torture of driving cars eight years ago?

Well, maybe it's just not that bad. Magrath drove it to Monterey and back and came out loving the thing. As for me, I did a 4.5-hour freeway drive last night. It wasn't great, but it wasn't terrible either. I didn't have any CDs with me, so I ended up listening to the radio at points where I decided my ears could tolerate both music and road noise. Classic rock (Van Halen, Led Zeppelin) seems to suit the car's character. And most other motorists seem to give this car some respect when you come up behind them. That's right, American Muscle here. Get your cruise-control-set Camry out of the way, please.

I think a car like our 2002 Corvette Z06 should be hand-washed for a couple of reasons. The first one can't be avoided — the Z06's super-low ride height makes the car just too low to go through most automated (track-based) car washes. Even if the front airdam somehow clears it's likely that the chassis will scrape or hang up, too. But honestly, is hand washing that difficult? It's a Z06, for heaven's sake. Treat it with some admiration. I hope other owners feel the same way.

Also, I'm curious what your thoughts are on washing a car yourself (either at home or coin-op) versus a professional car wash, particularly in regards to environmental impact. Maybe you've read write-ups like this one that argue that a professional car wash is better because it uses less water and cycles its waste water through the sewer rather than a storm drain. The sewer part makes sense to me but most of the estimates I've seen for hand-wash water useage at home (in the realm of 80 to 140 gallons) seem way over-inflated to me. I'm sure I use fewer than 10 gallons total washing a typical car at home. Spray off the car (a couple gallons maybe), fill up a bucket (three or four gallons), wash and spray off. Done.